Coater is the core equipment of anode and cathode coater in the first stage of lithium battery production. The so-called coating, is from the substrate into the coater to the coating after the substrate out of the coater a number of continuous processes. "To do a good job, you must first improve the machine", a high speed, high precision, high stability coater, can produce uniform thickness, high consistency of the pole sheet, laying the foundation for the next manufacturing of higher capacity lithium battery.

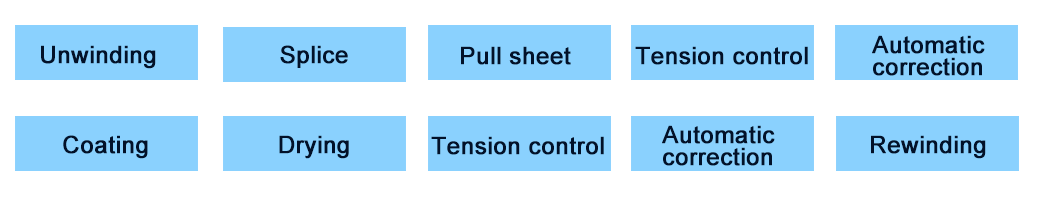

Coater process flow

The above process, such as unwinding and winding diameter, coating thickness and accuracy, accuracy of correction, are factors or parameters that affect the coating performance of lithium battery anode and cathode sheet, which requires sensors to help the coater to accurately monitor and efficiently produce!

In this issue, we understand the application of Lambao sensor in coater.

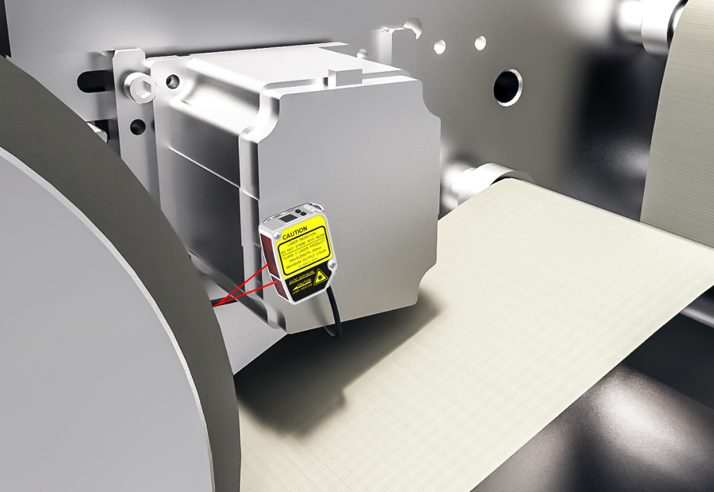

01 Coating thickness detection

The Lambao laser ranging sensor PDA series is installed above the conveying line track, which can accurately detect the thickness of the positive and negative slurry coating in the front, middle and back three sections of the pole piece, so as to avoid too low or too high battery capacity and affect the battery life.

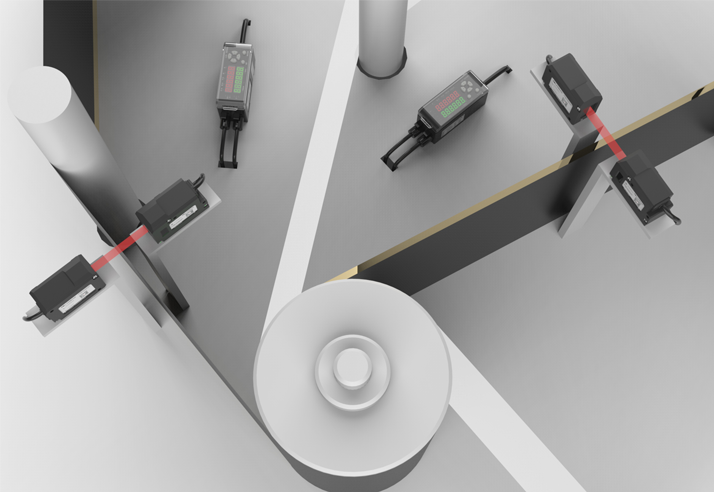

02 Foil coating for deflection correction

Lambaol CCD linear diameter measuring sensors are installed on the foil feeding and unwinding conveyor tracks. By comparing the deviation between the tested value and the designed value, the edge of the coil can be quickly corrected to avoid the coating-machine error and improve the working efficiency.

03 Remaining film thickness detection

Lambao laser ranging sensor PDB series installed on the production line, can detect the thickness of the remaining coil, high precision, fast sampling speed, can accurately control the material surplus, avoid the waste of coil film.

Today, many customers use Lambao sensors to help automated production, not only improve production efficiency and product quality, but also achieve the purpose of cost reduction and efficiency. In the future, Lambao Sensor will adhere to the original intention, cast high-quality sensors, to provide high-quality services for coater manufacturers.

Recommends

PDA-Laser Measuring sensor PDB-Measuring Displacement Sensor PDM-CCD-Measuring Sensors

Post time: Jan-10-2023