What is a bottle sharpening machine? As the name suggests, it is an automated mechanical device that organizes bottles. It is mainly to organize the glass, plastic, metal and other bottles in the material box, so that they are regularly discharged on the conveyor belt of the production line, so as to transfer the bottles to the next process. Its emergence effectively improves the production line operation efficiency and product quality, favored by pharmaceutical, food, beverage and other industries.

" If the bottle sorting machine is so popular, what are the devices that help it? Today, let's take a look at the specific application of Lambao sensor in bottle sorting machine, and decrypt the efficient working method of bottle sorting machine together."

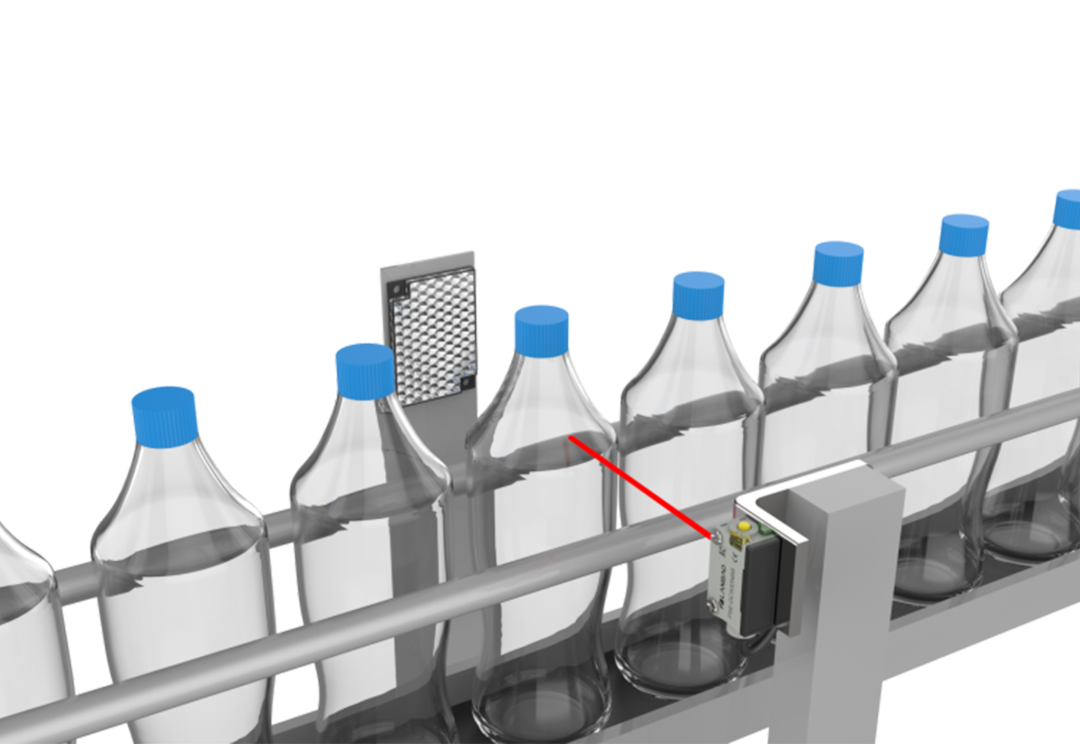

Transparent bottle inspection

" Before filling, it is necessary to locate transparent packaging bottles/cans on the production line or cooperate with a counter for counting and detection, so as to prevent congestion in the rear bottles during filling. However, the general photoelectric sensor always fails to detect the instability of transparent objects. In this case, Lambao PSE-G series photoelectric sensor can be used with coaxial optical design. Stable detection of transparent objects, and no detection blind area."

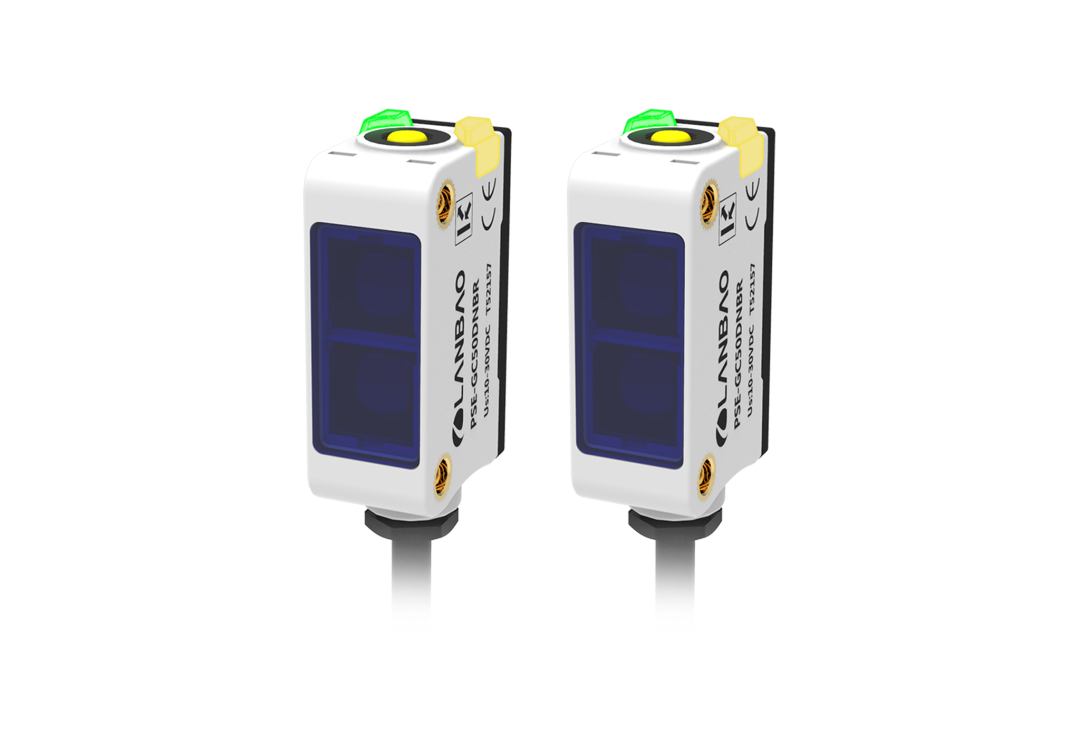

Product characteristics

• Normally open and normally closed can be switched

• IP67 compliant, suitable for harsh environments

• Coaxial optical design, no detection blind area

• Sensitivity one-button setting, setting accurate and fast

• Can stably detect various transparent bottles and various transparent films

There are liquid packaging bottles tested

" When filling, it is necessary to detect the height of liquid in the bottle to prevent excessive filling and overflow. At this time, Lambao's PFR fiber heads +FD2 fiber amplifier can be used to install the light head against the mouth of the bottle, and the liquid level height can be easily identified by the different light return amount of liquid at this position."

Product characteristics

• Standard thread shape for easy installation and use

• The optical fiber head is made of stainless steel with high durability

• Suitable for installation in narrow space, high detection accuracy

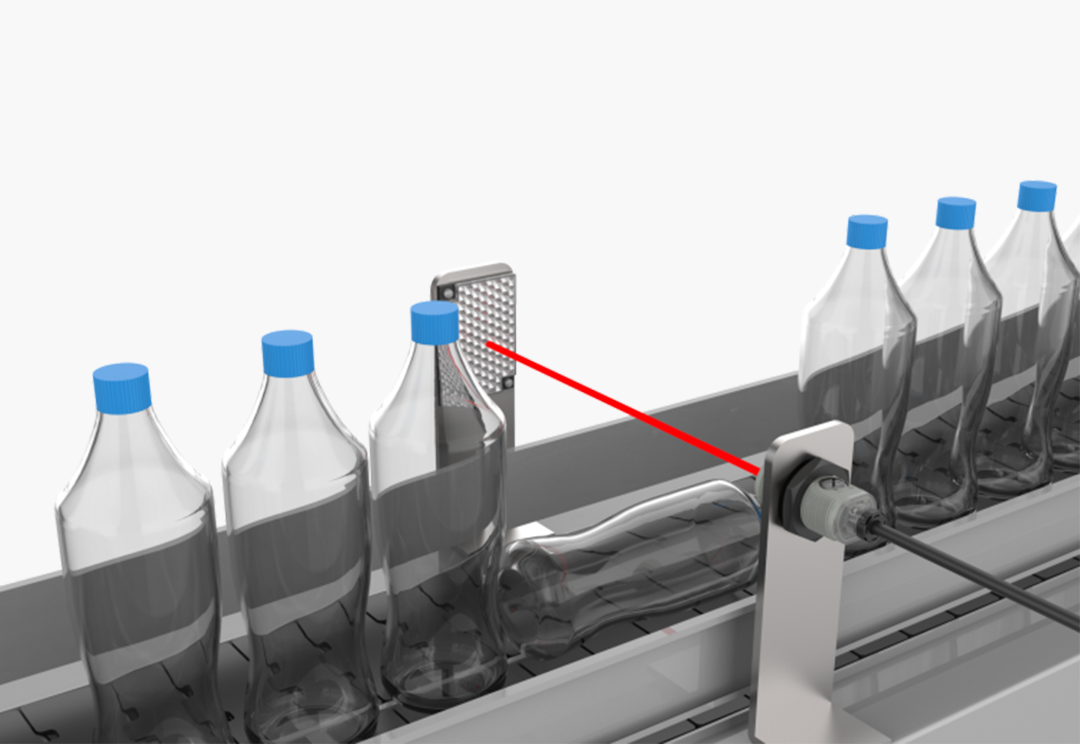

Bottle condition detection

" When the bottles are transported on the production line, some of them will fall over, which will lead to the failure to complete the subsequent process, or even lead to the passive stop of the subsequent production. At this time, the state of the bottles can be detected by Rambault PSS-G series photoelectric proximity sensors."

Product characteristics

• IP67 compliant, suitable for harsh environments

• 18mm thread cylindrical installation, easy installation

• Suitable for testing smooth transparent bottles and transparent films

• Bright LED status indicator with 360° visibility

• Short case to meet the requirements of narrow installation space

Post time: Mar-14-2023