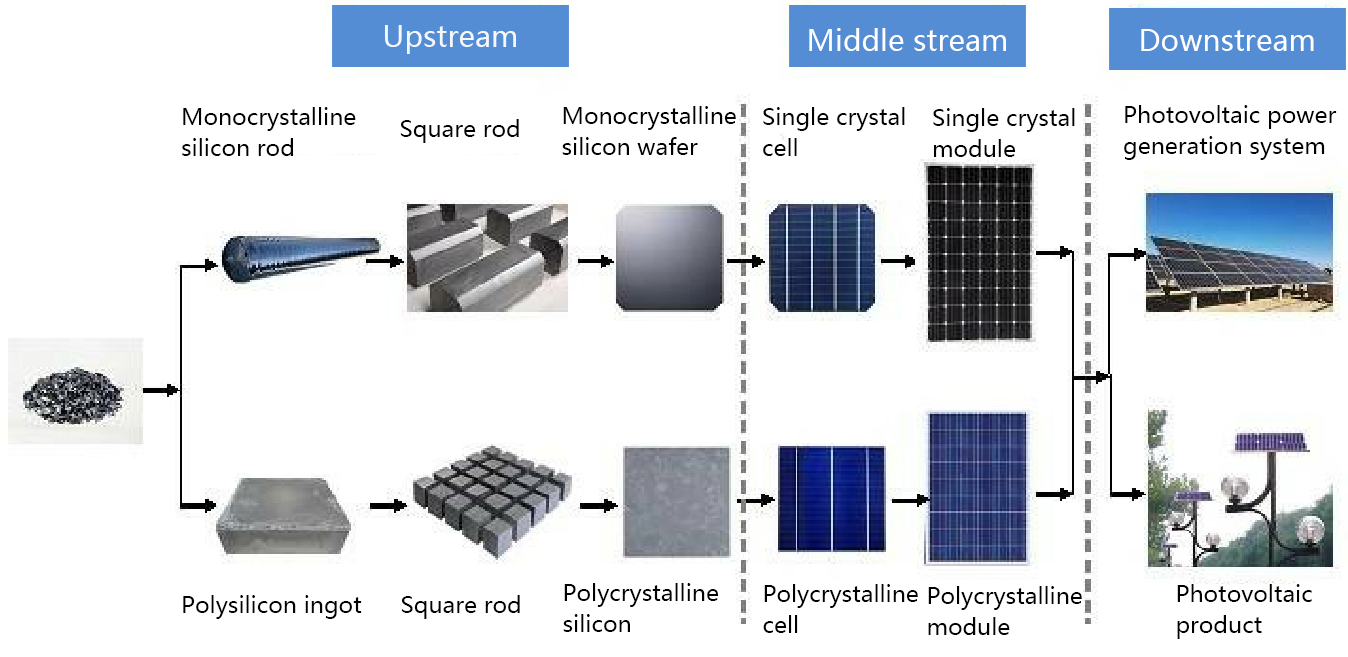

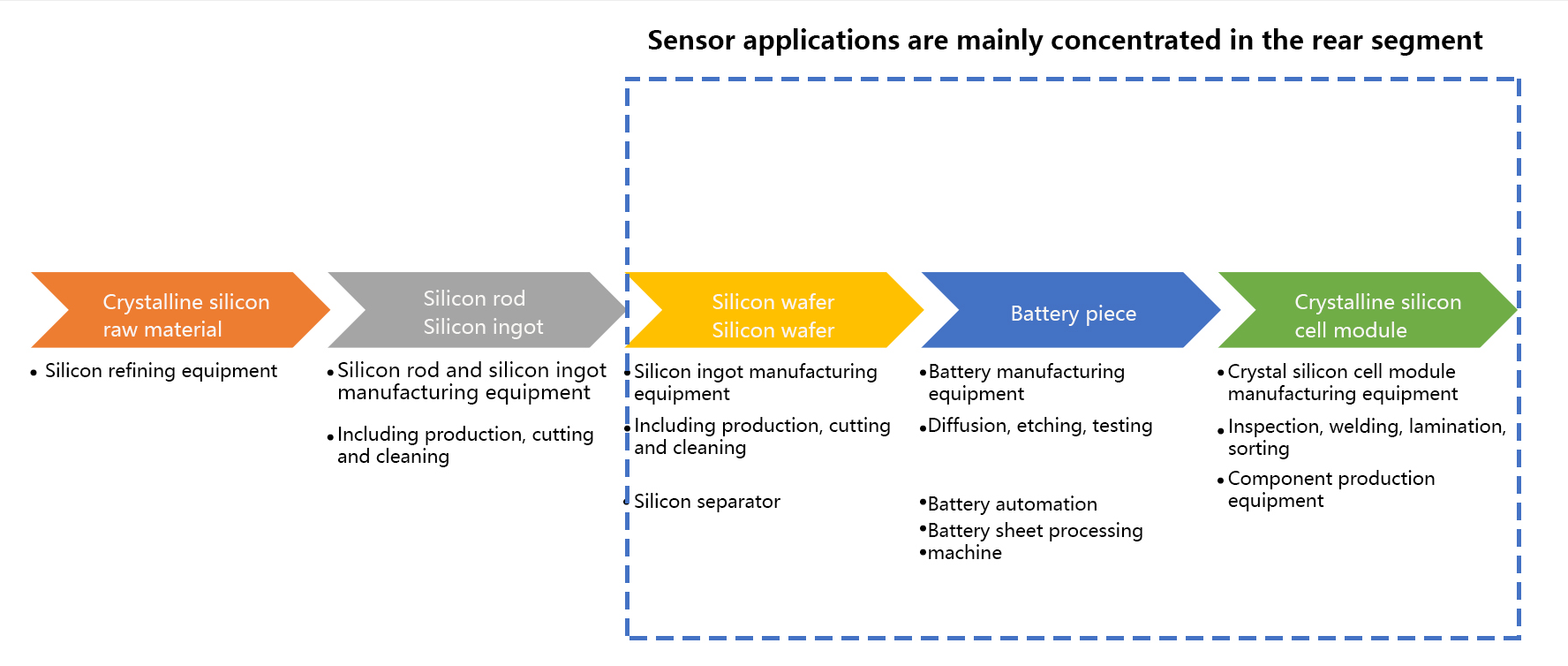

As a clean renewable energy, photovoltaic plays an important part in the future energy structure. From the perspective of the industrial chain, photovoltaic equipment production can be summarized as upstream silicon wafer manufacturing, midstream battery wafer manufacturing and downstream module manufacturing. Different processing equipment is involved in each production link. With the continuous improvement of production technology, the precision requirements for production processes and related production equipment are also constantly improving. In each process production stage, the application of automation equipment in the photovoltaic production process plays a key role in connecting the past and the future, improving efficiency and reducing costs.

Batteries play a pivotal role in the entire production process of the photovoltaic industry. Each square battery shell is composed of a shell and a cover plate which is the core component to ensure the safety of the lithium battery. It will be sealed with the shell of the battery cell, the internal energy output, and ensure the key components of the safety of battery cell, which has strict requirements for component sealing, relief valve pressure, electrical performance, size and appearance.

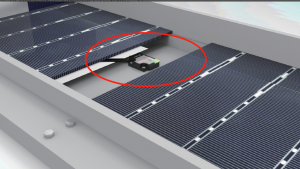

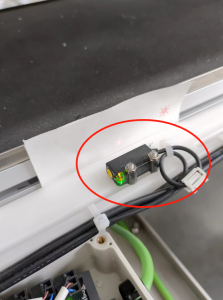

As the sensing system of automation equipment, sensor has the characteristics of accurate sensing, flexible installation and fast response. How to choose a suitable sensor according to specific working condition, in order to achieve the purpose of cost reduction, efficiency increase and stable operation. There are various working conditions in the production process, different ambient light, different production rhythms and different color silicon wafers, such as silicon after cutting diamond, gray silicon and blue wafer after velvet coating, etc. both have strict requirements. Lanbao sensor can provide a mature solution for the automatic assembly and inspection production of battery cover plate.

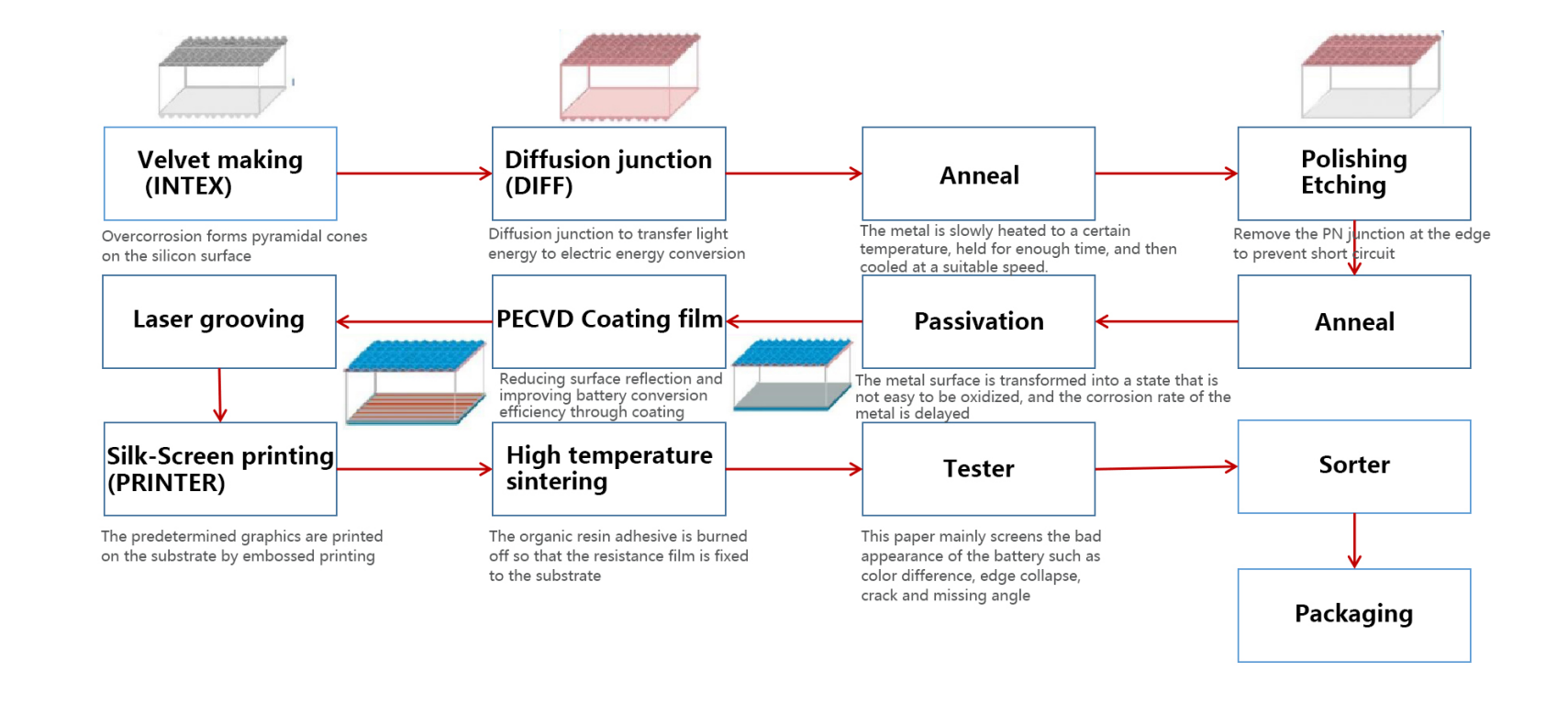

Passivated Emitter Rear Contact, namely passivation emitter and back passivation battery technology. Usually, on the basis of conventional batteries, aluminum oxide and silicon nitride film is plated on the back, and then the film is opened by laser. At present, the conversion efficiency of PERC process cells has been close to the theoretical limit of 24%.

Lanbao sensors are rich in species and widely used in various process segments of PERC battery production. Lanbao sensors can not only achieve stable and accurate positioning and spot detection, but also meet the needs of high-speed production , boosting the efficiency and cost reduction of photovoltaic manufacturing.

Sensor applications of cell machine

| Working position | Application | Product |

| Curing oven, ILD | Place detection of metal vehicle | Inductive Sensor-High temperature resistant series |

| Battery production equipment | Place detection of silicon wafer, wafer carrier, railboat and graphite boat | Photoelectric Sensoe-PSE-Polarized reflection series |

| (Screen printing, track line, etc.) | ||

| Universal station - Motion module | Origin location | Photoelectric Sensor-PU05M/PU05S sloat slot series |

Sensor applications of cell machine

| Working position | Application | Product |

| Cleaning equipment | Pipeline level detection | Capactive Sensor-CR18 series |

| Track line | Presence detection and spot detection of silicon wafer; Presence detection of wafer carrier | Capacitive sensor-CE05 series,CE34 series, Photoelectric sensor-PSV series (convergent relection), PSV series (backgroud suppression) |

| Track transmission | Detection of wafer carrier and quartz boat location |

Cpacitive Sensor-CR18 series, photoelectric sensor-PST series (background suppression/ through beam reflection), PSE series (through beam reflection) |

| Suction cup, buff below, mechanism lift | Presence detection of silicon chips |

Photoelectric sensor-PSV series (convergent reflection), PSV series (backgroud suppression), Cpacitive Sensor-CR18 series |

| Battery production equipment | Presence detection of wafer carrier and silicon chips/ Position detection of quartz | Photoelectric sensor-PSE Series (background suppression) |

Post time: Jul-19-2023