On July 24th, the first "three typhoons" phenomenon of 2025 (" Fanskao ", "Zhujie Cao", and "Rosa") occurred, and the extreme weather has posed a huge challenge to the wind power equipment monitoring system.

When the wind speed exceeds the safety design standards of the wind farm, it may lead to blade breakage and damage to the tower structure. The heavy rain brought by typhoons may cause problems such as moisture and leakage of electricity in equipment. Coupled with storm surges, it may lead to instability or even collapse of the wind turbine foundation.

In the face of increasingly frequent extreme weather conditions, we can't help but ask: Should we continue to bet on the climate war of the 21st century with the operation and maintenance methods of the 20th century, or should we arm every wind turbine with digital "iron armor"?

Lanbao's inductive, capacitive and other intelligent sensors collect key parameters of components such as blades, gearboxes and bearings in real time, building the "nervous system" armor of wind power equipment, making sensors an invisible driving force for the intelligent upgrade of wind power.

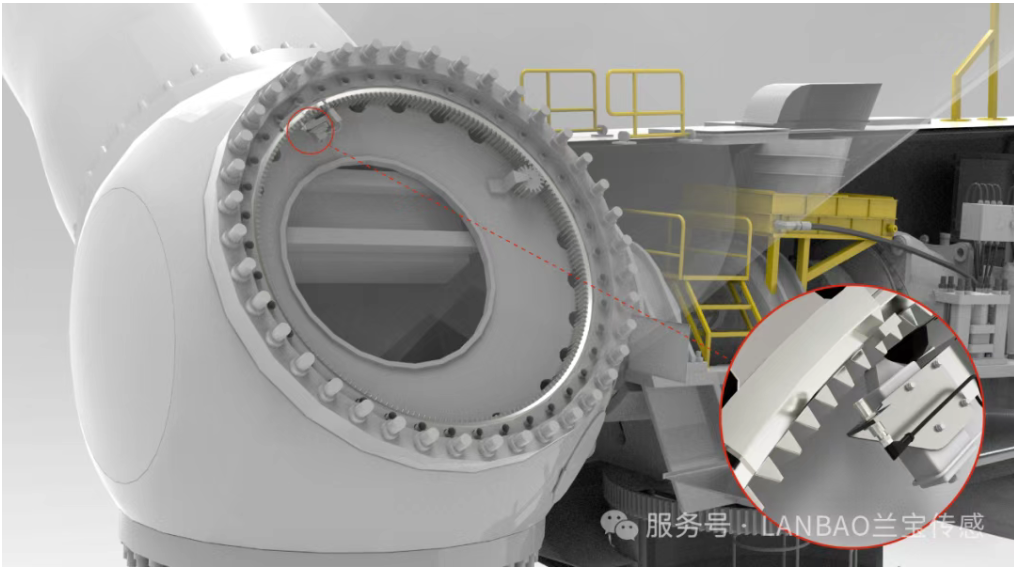

01. Pitch Angle accuracy detection

During the self-rotation of the blades, the LR18XG inductive sensor from Lanbao detects the metal markers at the end of the rotating blades in the electric pitch system to determine whether the blades have rotated to the preset Angle. When the blades reach the target position, the inductive sensor outputs a switch signal to ensure that the pitch Angle is within a safe range, thereby optimizing the wind energy capture efficiency and avoiding the risk of overloading.

02. Speed monitoring on the low-speed side

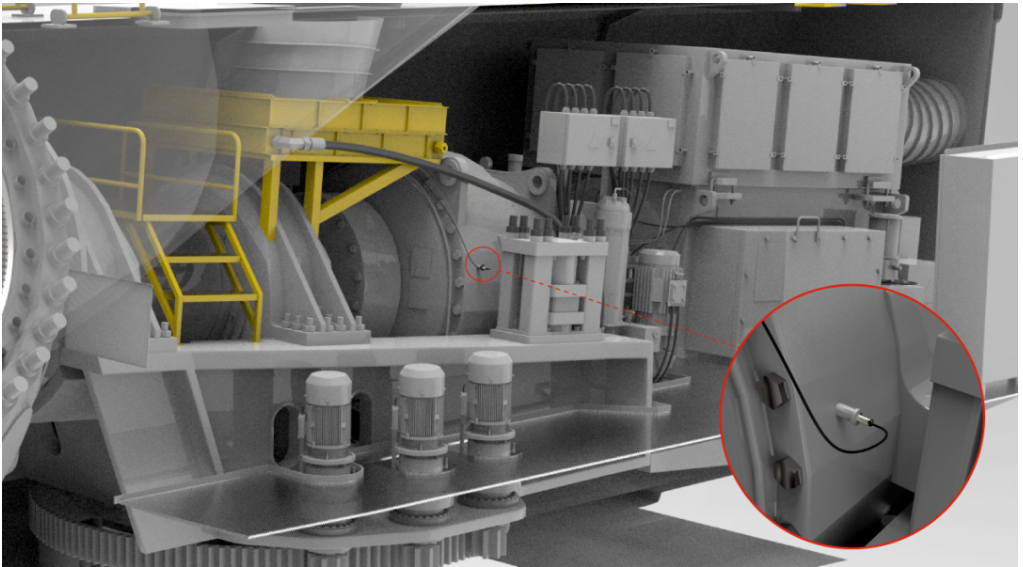

In the process of wind power generation, the rotational speed of the blades must be within a certain range. In severe weather conditions such as typhoons, to prevent mechanical damage to wind turbines caused by overspeed, it is necessary to monitor the main shaft speed in real time.

The Lanbao LR18XG inductive tspeed sensor installed at the front end of the main shaft (slow shaft) monitors the rotor speed in real time, providing key data for fault diagnosis of the transmission system or couplings.

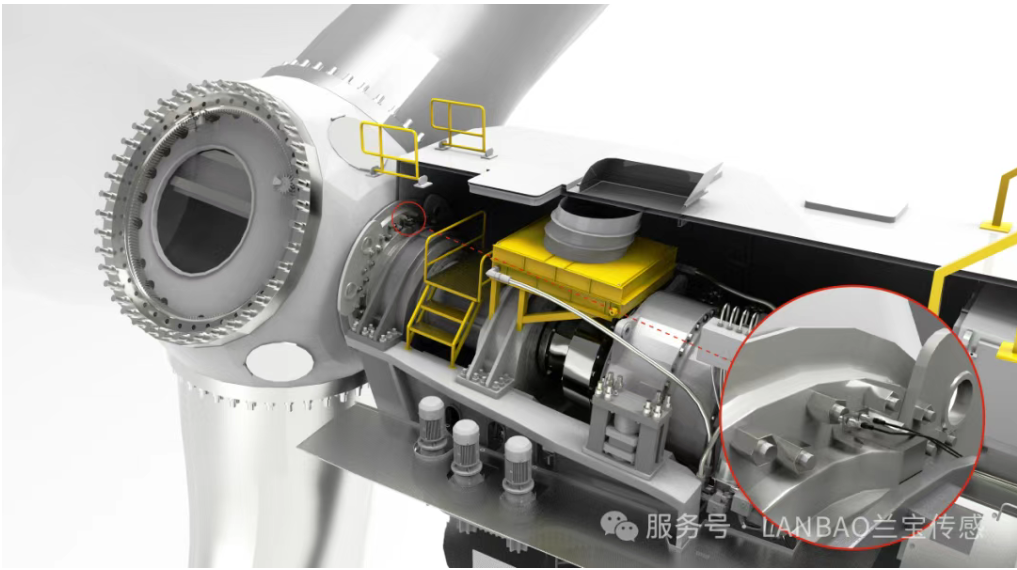

03. Hub rotation concentricity detection

In wind turbines, damage to the generator and water pump often occurs due to bearing vibration, imbalance and cavitation. Bearings are the core components of the mechanical transmission system of wind turbine units. Many faults of gearboxes, blades, etc. are also caused by bearing failures. Therefore, real-time monitoring of the operating status of bearings is of vital importance.

The Lanbao LR30X analog sensor can effectively identify the fault modes of bearings by collecting and analyzing vibration signals, providing data support for subsequent fault diagnosis and maintenance.

04. Liquid level height detection

The Lanbao CR18XT capacitive sensor monitors the oil level in the gearbox in real time and issues an alarm signal when the oil level drops below the preset threshold. The capacitive liquid level monitoring sensor supports contact-based medium identification and can calibrate parameters according to the characteristics of different oils.

As the wind power industry accelerates its transformation towards intelligence and digitalization, sensor technology is playing an irreplaceable bridging role. From blades to gearboxes, from towers to pitch systems, densely deployed sensors continuously deliver precise data on the health status of the equipment. These real-time collected parameters such as vibration, displacement and speed not only lay the foundation for predictive maintenance of wind power equipment, but also continuously optimize the operational efficiency of the units through big data analysis.

With the deepening application of sensor technology, Lanbao sensors will play a key role in the full life cycle management of wind power equipment, providing continuous technological impetus for the wind power industry to achieve the goal of cost reduction and efficiency improvement.

Post time: Aug-26-2025