From May 15th to 17th, the 3-day 17th Shenzhen International Battery Technology Exchange Conference (CIBF2025) successfully concluded! As a key vane in the global battery industry, this exhibition focused on battery technological revolution and collaborative innovation across the entire industry chain, bringing together more than 3,000 top enterprises worldwide, aiming to inject surging momentum into the global energy transition.

01 Booming popularity

Live from Lanbao's Booth Scene

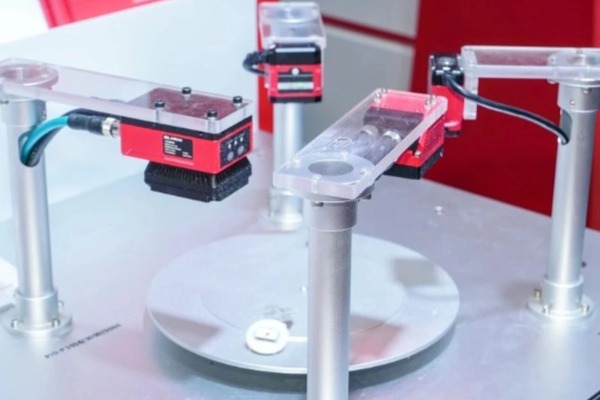

Lanbao Sensing made a grand debut at the exhibition with cutting-edge sensing technologies and intelligent solutions. Starting from the key links of battery production, it provides precise quality control and efficiency improvement for battery manufacturing through highly reliable and explosion-proof sensor products and intelligent system solutions!

The sensors independently developed and produced by Lanbao Sensing build a solid foundation for products with "full-life-cycle quality control". While the ex-factory products meet the established industry standards, they are also synchronously certified in compliance with UL, CCC, CE, UKCA, EAC, E-Mark and other certification systems according to market demands.

02 Star Products for Lithium Batteries--Explosion-proof design, free of copper, zinc and nickel

Directly address industry pain points

Star Products for Lithium Batteries

Lanbao Inductive Intrinsically Safe Sensor

◆ Product advantages

- Rich installation specifications and multiple product sizes;

- Multiple circuit protections ensure stable and reliable output signals;

- Sturdy metal casing enables longer detection distance;

- Adoption of excellent EMC technology design ensures more stable product performance.

◆ Mechanical Position Detection in the Oven of Coating Machine

【on of mechanical shafts in the oven】

Star Products for Lithium Batteries

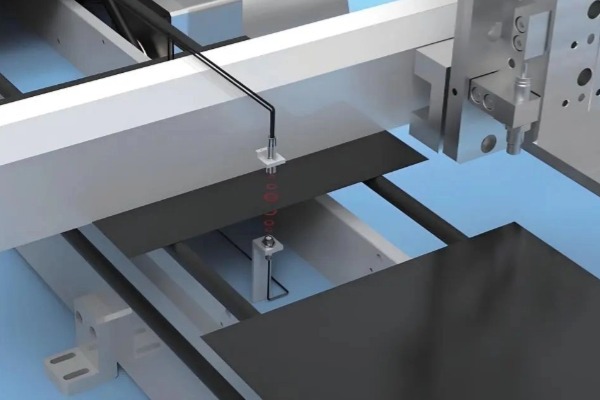

Lanbao LVDT Contact Displacement Sensor

◆ Product Advantages

- Micron-level repeatability accuracy;

- Multiple measurement ranges (5...20mm);

- Diverse (dimensions) to suit various application spaces;

- Comprehensive output modes, including switching quantity, analog quantity, and RS485;

- Induction head pressure as low as 1.7N enables non-wearing detection on both metal and glass surfaces.

◆ Detection of Electrode Sheet Roll Gap

The main purpose of blade gap detection in coating machines is to ensure that the gap between the blade and the coating roller remains within a precise range during the coating process, thereby guaranteeing the coating quality.

Star Products for Lithium Batteries

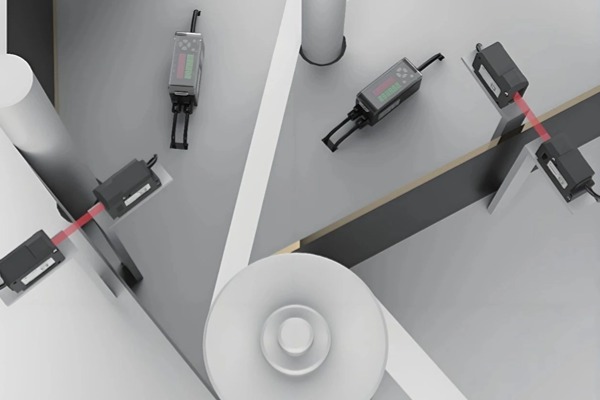

Lanbao CCD Wire Diameter Measurement Sensor

◆ Product Advantages

- Stable & Reliable Detection: Utilizes advanced algorithms and optical systems for consistent, high-precision measurements.

- Non-Contact Design: Features a simple structure with no physical contact, ensuring fast measurement speed, minimal wear, and long-term stability.

- High Performance: Boasts high sensitivity, low distortion, vibration resistance, magnetic field immunity, compact size, and no afterimage.

◆ Material Edge Alignment Measurement

When winding lithium-ion battery cells, it is necessary to ensure that the position of the cell does not deviate during the winding process.

Star Products for Lithium Batteries

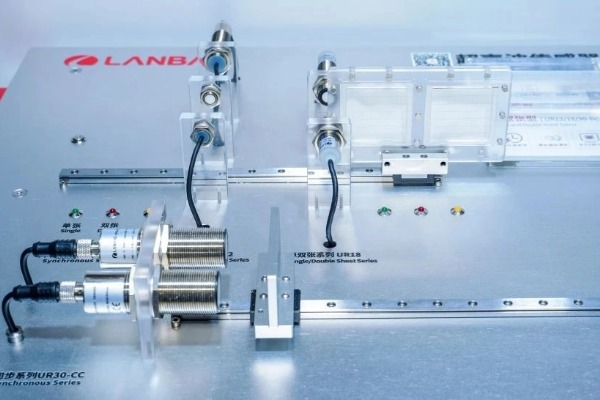

Lanbao Ultrasonic Sensor UR18DC Series

◆ Product Advantages

- Built-in temperature compensation function;

- 3-channel NPN/PNP outputs;

- Capable of detecting single and double sheets of various materials;

- Material learning function via teach-in wire for adapting to different substances.

◆ Double-sheet detection for electrode sheets on laminators

【Detection of single and double electrode sheets】

Star Products for Lithium Batteries

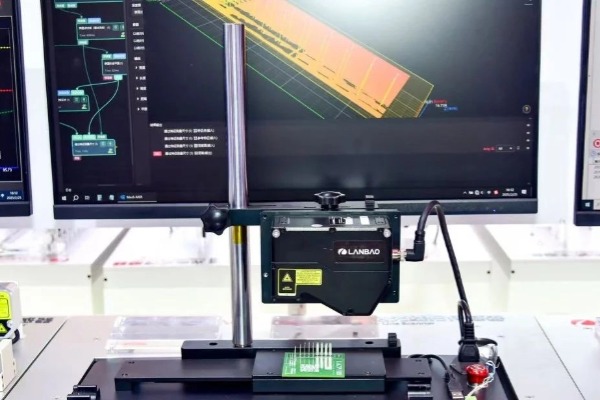

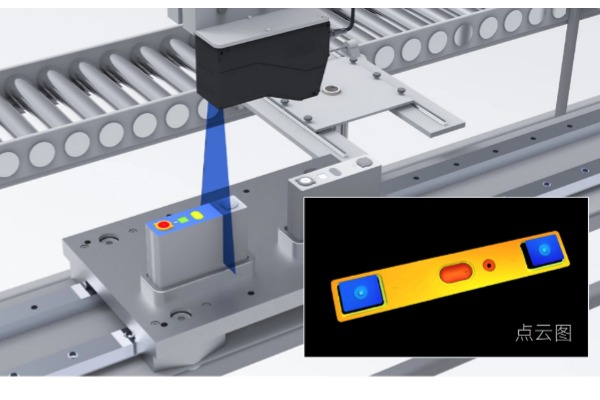

Lanbao 3D Line Scan PHM6000 Series Laser Sensors

◆ Product Advantages

- Flexible output modes and multiple specifications available;

- Precise detection capability and powerful operation functions;

- Stable imaging for highly reflective top covers with a missed detection rate < 0.1%;

- Completes workpiece scanning within 1 second, featuring high measurement accuracy (detection accuracy < 0.01mm).

◆ Measurement of Planarity and Step Difference for Lithium Battery Cell Top Covers

Before welding the top cover of a lithium battery cell to the aluminum casing, the following measurements must be performed:

- Planarity of the top cover: Detection accuracy must be ≤0.02mm.

- Step difference between the top cover and aluminum casing: The height difference must be ≤0.25mm, with a detection accuracy of ≤0.02mm.

Welding can only proceed after these requirements are met.

Star Products for Lithium Batteries

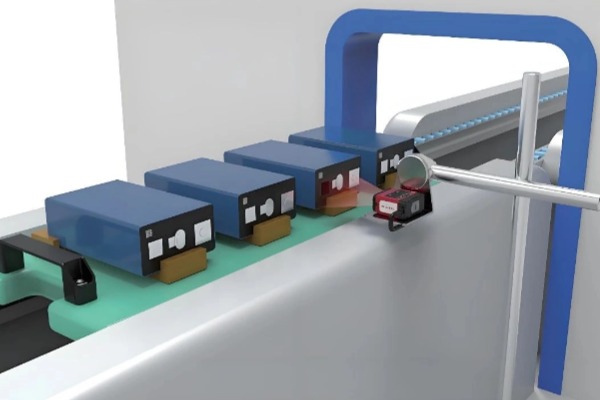

Lanbao Intelligent Code Reader PID Series

◆ Product Advantages

- Operates online without requiring additional downtime;

- Enables stable on-site barcode recognition with a reading rate of over 99.99%;

- Achieves high-speed code reading, completing the entire process of code reading, decoding, and communication feedback within 150ms.

◆ Barcode Information Reading

In the middle-stage process of prismatic battery production, the main function of the casing loading station is to insert the bare cell into the casing and pre-weld the cell cover with the casing opening. Before performing the casing loading operation, the QR code on the battery cover must be identified.

At this exhibition, Lanbao Sensing demonstrated the technical depth of our sensor applications in various lithium battery automation equipment. In the future, Lanbao will continue to refine its products, deepen its presence in the lithium battery industry, assist enterprises in breaking through production bottlenecks and improving efficiency, and inject intelligent sensing power into the global energy transition!

Post time: May-21-2025