The moisture content of wheat directly affects its quality and storage conditions. Excessive moisture can easily lead to issues such as mildew, germination, and pest infestations, reducing wheat quality and impacting processing and consumption. Conversely, insufficient moisture can cause wheat to break easily, affecting both processing and storage. Therefore, strict control of wheat moisture content is crucial for ensuring its quality and extending its storage period.

Compared to the traditional oven-drying method, the intelligent microwave moisture analyzer demonstrates significant advantages in wheat detection:

• High Precision

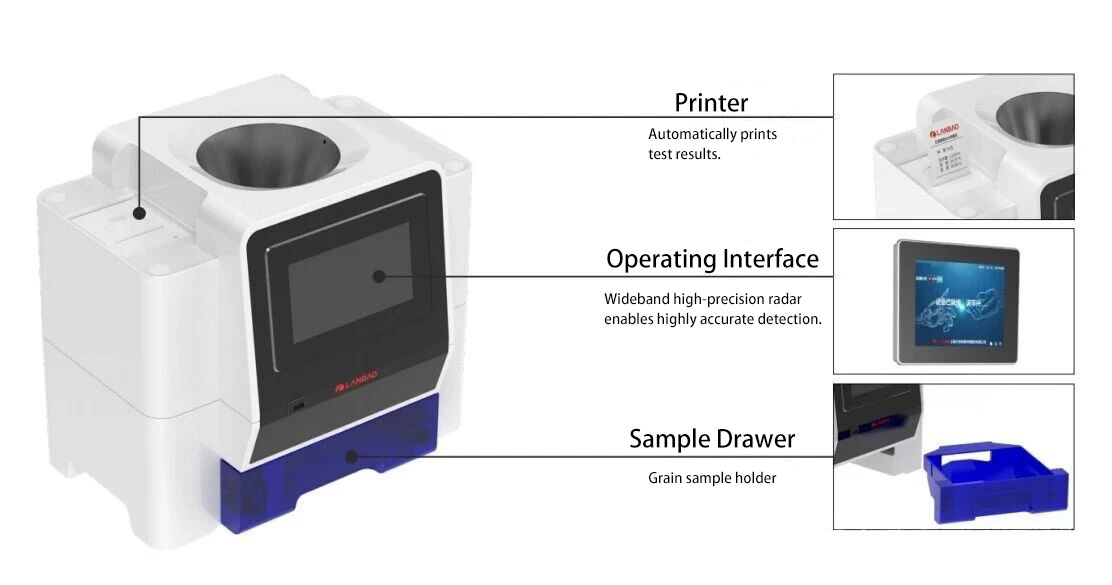

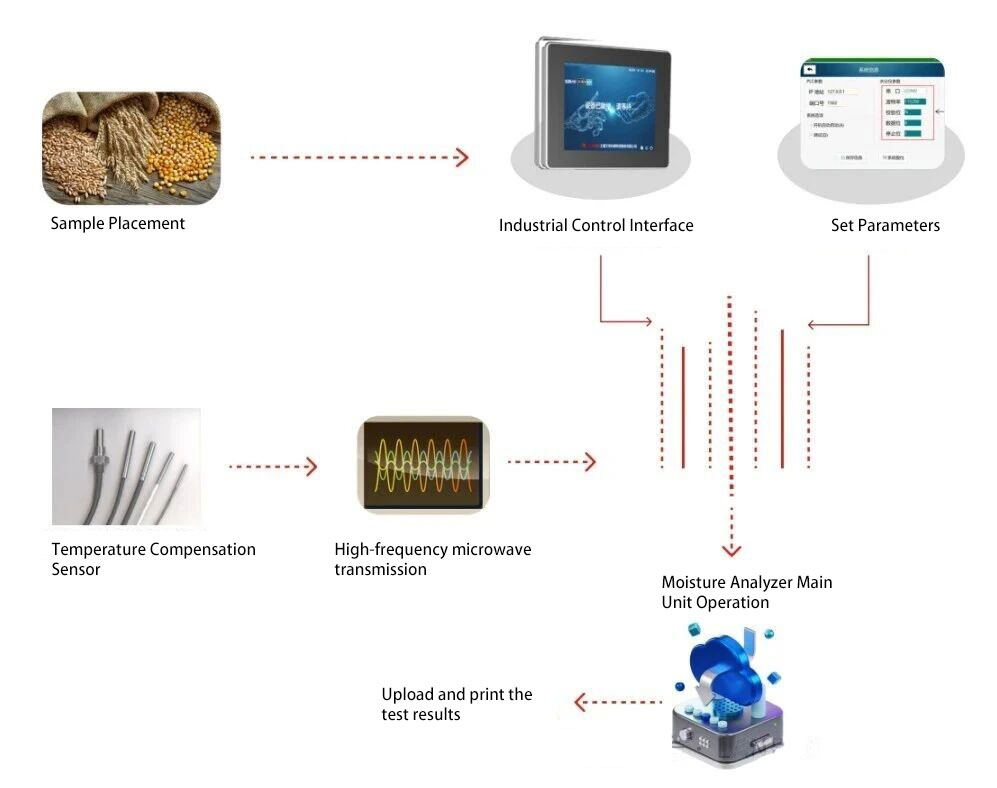

The device employs wideband high-precision radar to achieve highly accurate measurement of the comprehensive moisture content inside the sample.

• Rapid and Non‑Destructive Testing

It enables real‑time, non‑destructive moisture analysis of grains, with fast detection speed (within 1 minute), high accuracy, low sensitivity to grain origin, and a wide dynamic range.

• Real‑Time Microwave Response

The microwave field responds rapidly, providing real‑time feedback of measurement results.

• Temperature Compensation

Equipped with a high‑precision temperature sensor for real‑time temperature compensation, making it suitable for different temperature environments.

• Wide Applicability

Widely applicable to moisture content measurement in various materials. Detection accuracy is not affected by ambient temperature, dust, light, or material color.

LANBAO Intelligent Microwave Moisture Analyzer

Based on an embedded system operating platform, this detection system not only achieves precise moisture monitoring, but also serves as a crucial link in industrial process automation by continuously supplying reliable moisture data. The real‑time measurement results can directly feed into automated process control, ensuring efficient and precise moisture regulation and detection.

| Model | MSD-MGO1A |

| Working temperature | 0-50°C |

| Working humidity | <70% |

| Power supply source | 100-240VAC/50Hz |

| Overall power consumption | <100W |

| Measurement cycle | 0-60S |

| Measurement range of moisture | 5%-35% |

| Measurement accuracy of moisture | <0.50% |

| Signal output form | Display, Label Printing, Communication |

| Size of touch screen | 7-inch |

| Size of main unit | 425mm*290mm*376mm |

| Sample capacity | <1L |

Core Application Scenarios of Wheat Moisture Detection

The Intelligent Microwave Moisture Analyzer covers key stages of the wheat industry chain, with specific applications including:

Pre‑warehouse Quality Management: Wheat with moisture content exceeding 15% is prone to mildew. The microwave moisture analyzer provides second‑level moisture data to ensure wheat meets the safe storage standard (12%‑14%).

Storage and Ventilation Optimization: In silos or warehouses, the microwave moisture analyzer monitors changes in the moisture content of stored wheat, preventing pest infestation or sprouting caused by moisture regain and extending shelf life.

Quality Control During Transportation: At ports or during transit, the microwave moisture analyzer safeguards wheat quality by ensuring moisture content remains ≤14% through continuous monitoring.

The application of intelligent microwave moisture analyzers in wheat moisture detection is witnessing rapid adoption and an intelligent upgrade trend. Against the backdrop of food security strategies, the core significance of microwave moisture analyzers lies in enabling efficient, precise, and non-destructive online monitoring. They provide critical data support for quality control during grain storage and transportation, thereby enhancing the quality and efficiency of the grain industry.

Post time: Feb-11-2026