In the automotive manufacturing sector, sensors play a pivotal role—acting as the "sensory organs" of vehicles, continuously detecting and transmitting critical data throughout the production process.

Like a highly responsive "intelligent neural network," Lanbao sensors are deeply embedded in and optimize every key stage—from body welding, paint application, quality inspection, to production line safety and environmental monitoring. With exceptional sensing capabilities and rapid response, they infuse intelligence and vitality into automotive manufacturing!

01-Lanbao sensor

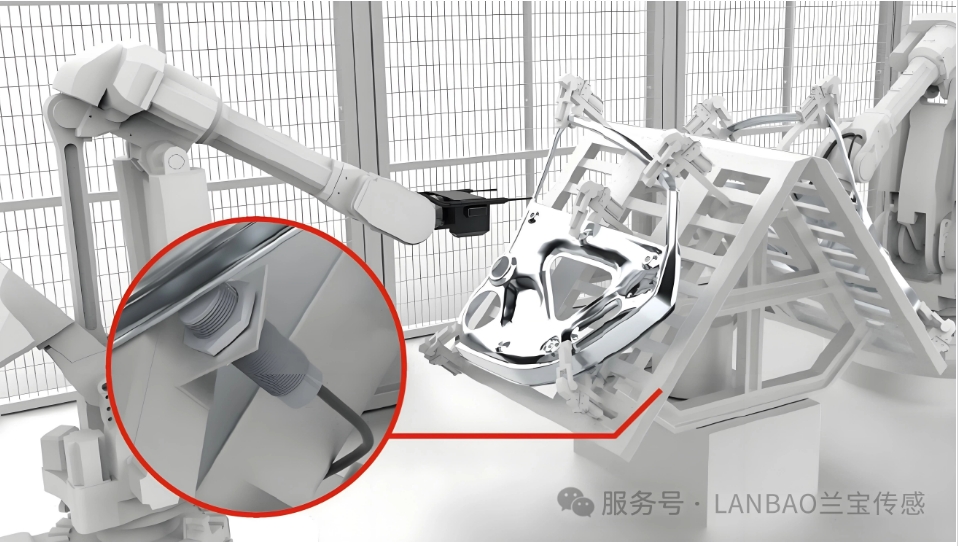

Auto Body Welding

Smart Positioning& Secure Operation

Lanbao Inductive Non-Attenuation Series Sensors achieve precise positioning of automotive components, with their anti-interference capability ensuring stability in subsequent welding processes.

Lanbao Inductive Welding-Immune Sensors resist strong magnetic interference and remain unaffected by welding spatter adhesion, enabling reliable detection of door panel positions and welding status to prevent defects.

Lanbao Photoelectric Slot Sensors guarantee accurate positioning of tray transfer modules, while Landtek 2D LiDAR Sensors provide navigation and obstacle avoidance for AGVs, enabling automated material handling.

Together, these solutions enhance production efficiency and intelligent manufacturing capabilities.

02-Lanbao sensor

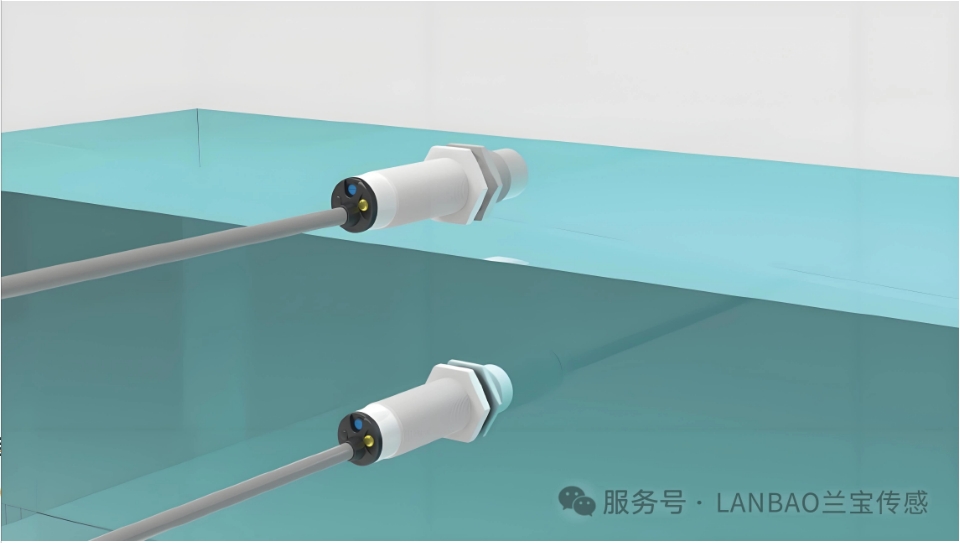

Painting Shop

Smart Monitoring & Automatic Replenishment

The Lanbao high-temperature resistant material level capacitive sensor plays the role of a "smart brain" in the liquid level monitoring of paint tanks in the spraying workshop. They sense the changes in liquid level (non-conductive liquid) in real time and automatically trigger replenishment to ensure the continuity and stability of the spraying operation. Intelligent monitoring combined with artificial intelligence technology can reduce manual intervention, lower the probability of errors, precisely manage materials, improve resource utilization, and lower costs.

03-Lanbao sensor

Quality Inspection

Micro-Defect Prevention & Quality Upgrading

Lanbao Smart Barcode Readers ensure fast and accurate code scanning for automotive lamp seals, guaranteeing correct installation and reliable quality traceability.

Lanbao 3D Line Scan Sensors precisely detect weld point patterns, joint geometries, and tire surface defects to safeguard manufacturing quality standards.

04-Lanbao sensor

Production Line Safety & Environmental Monitoring

Comprehensive Protection & Risk Prevention

Lanbao safety light curtain is used to monitor dangerous areas during the production and manufacturing process. It will quickly alarm and stop the machine when personnel enter the dangerous area. The Lanbao safety door switch is mainly used to monitor the opening and closing status of the door and only allows the equipment to operate when the door is completely closed and locked. This type of security door lock can prevent unauthorized personnel from entering dangerous areas and ensure the safety of the working environment. The high reliability of these sensors ensures the safety of people and equipment.

With cutting-edge performance and smart capabilities, Lanbao sensors are deeply integrated into every automotive production process, serving as a mission-critical enabler for Industry 4.0 transformation.

Post time: May-13-2025