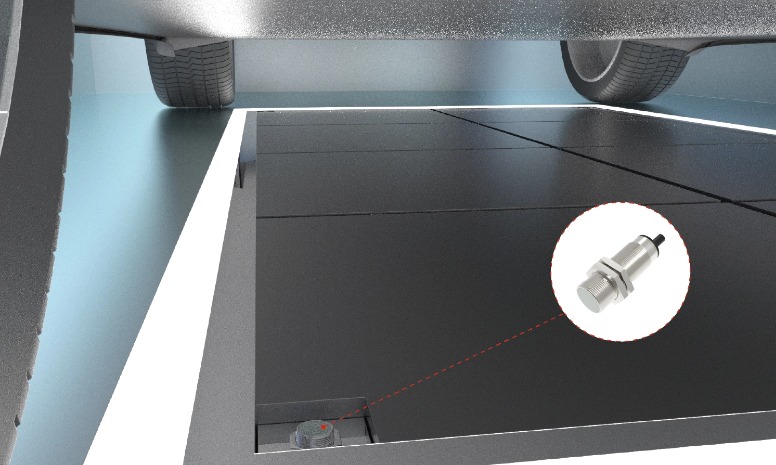

The Factor One inductive sensor offers an effective solution to these challenges.

Defined by a coefficient K≈1, non-attenuation ensures the sensor maintains an almost uniform detection distance across diverse metals, including iron, stainless steel, copper, and aluminum. This eliminates the need for repeated installation position adjustments for different vehicle models, enabling a single swap channel to accommodate multiple chassis configurations such as sedans and SUVs.

Boasting an extremely low attenuation coefficient, the sensor achieves a substantial extension in detection distance, generating longer-range and more stable trigger signals within a fixed installation space, thus providing enhanced mechanical tolerance for shuttle vehicles and battery pallets.

The Factor One inductive sensor

• Non-attenuation detection: The attenuation coefficient for different metals is approximately 1.

• Strong anti-interference capability: It passes EMC environmental testing and resists strong magnetic field interference.

• Enhanced distance detection: It features a longer detection distance, enabling flexible installation and easier position setting and target control.

• Wide application range: It supports the detection of various metal materials, meeting the needs of different industrial scenarios.

| Series model |

LR12XB |

LR18XB |

LR30XB |

| Rated distance |

4mm |

8mm |

15mm |

| Standard target |

Fe 12*12*1t |

Fe 24*24*1t |

Fe 45*45*1t500Hz |

| Switching frequency |

1000Hz |

800Hz |

500Hz |

| Mounting |

Flush |

| Supply voltage |

10-30VDC |

| Repeat accuracy |

≤5% |

| Anti-magnetic field interference |

100mT |

| Temperature drift |

≤15% |

| Hysteresis range [%/Sr] |

3....20% |

| Consumption current |

≤15mA |

| Residual voltage |

≤2V |

| Special features |

Factor 1 (iron,copper,aluminum,stainless steel attenuation < ±10%) |

| Circuit protection |

Short circuit,overload,reverse polarity |

| Output indicator |

Yellow LED |

| Ambient temperature |

-40~70C |

| Ambient humidity |

35...95%RH |

| Degree of protection |

IP67 |

| Connection way |

2m PVC cable |

| Housing material |

Nickel-copper alloy |

Application of The Factor One Inductive Sensor in Battery Swap Stations

Chassis Battery Positioning Detection

Battery Presence Detection on Loading Platforms

Jointly Build an Efficient, Safe and Intelligent Battery Swap System

The Factor One inductive sensor can also perfectly cooperate with other Lanbao products to jointly build an efficient, safe and intelligent battery swap system, thereby significantly improving both the safety and efficiency of battery swap stations.

Vehicle Warehouse Entry and Position Detection —— PTE-PM5 Photoelectric Sensor

RGV Operation Safety Detection —— SFG Safety Light Curtain

Fork Tooth Battery Position Detection —— PSE-YC35, PST-TM2 Photoelectric Sensors

Forklift Lifting/Operation Position Detection —— LR12X Enhanced Long-Distance Inductive Sensor

Battery Compartment Battery Presence Detection —— LR18X Enhanced Long-Distance Inductive Sensor

With the continuous iteration of technologies in the new energy vehicle energy supplement system and the expanding application scenarios, it will play an increasingly important role in promoting the large-scale popularization of the battery swap mode and boosting the high-quality development of the new energy vehicle industry.