As manufacturing precision and automation levels in the 3C electronics industry continue to advance, efficient and stable detection of metal components has become a critical factor in ensuring product quality and production line efficiency.

In this process, Lanbao's non-attenuating inductive sensors, with their outstanding performance and adaptability, are increasingly becoming an indispensable "perception powerhouse" in 3C manufacturing.

What is Factor 1 inductive sensor?

Non-attenuating inductive sensors, a type of inductive proximity switch, are distinguished by their ability to detect metal objects without being affected by material type. Their core advantage lies in maintaining a consistent sensing distance across different metals—such as iron, stainless steel, copper, and aluminum—without signal attenuation due to material variations. This unique characteristic makes them exceptionally well-suited for metal component inspection in the 3C electronics industry.

Lanbao non-attenuating inductive sensor

✔ Zero Attenuation Detection

Attenuation coefficient ≈1 for different metals (Cu, Fe, Al, etc.)

Detection tolerance ≤±10% across all supported metals

✔ Wide Material Compatibility

Supports detection of various metal types

Adaptable to diverse industrial applications

✔ Non-Contact Sensing

Eliminates mechanical wear

Extends service life and reduces maintenance costs

✔ High-Speed Response

Ideal for high-speed production lines

Ensures real-time detection and control

✔ Superior EMI Resistance

Passes EMC compliance tests

Withstands strong magnetic interference

Specific applications of Lanbao non-attenuation sensors

Metal parts loading station

Check whether the parts are missing or wrongly installed

In the automatic feeding system, Lanbao non-attenuation sensors are used to detect whether parts are in place, preventing missed or incorrect installation. For instance, at the feeding ports of metal parts such as the middle frames of mobile phones and the bottom shells of laptops, sensors can precisely identify whether the parts exist, ensuring that robots or mechanical arms can accurately grasp them.

Transmission line body monitoring

Real-time monitoring of parts and emergency safety protection

During the conveyor belt or workpiece carrier transportation process, sensors can monitor the flow state of metal parts in real time. Once a missing part or positional shift is detected, the system can immediately sound an alarm and stop the transmission to prevent defective products from flowing into the next workstation.

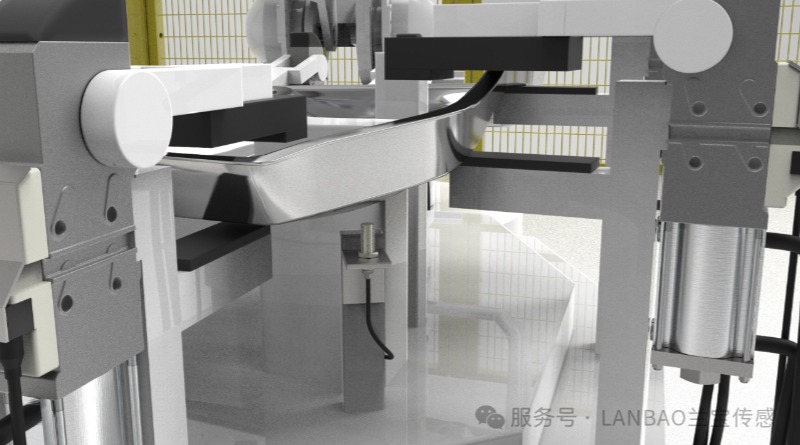

Positioning inspection before welding/riveting

Detection of whether the part is embedded in the fixture

Before the ultrasonic welding or riveting station, the Lanbao non-attenuation sensor is used to confirm whether the metal parts are in place and ensure the welding accuracy. For instance, before welding the metal parts of the notebook hinge, the sensor can detect whether they are accurately embedded in the fixture.

Finished product inspection and sorting

High-efficiency sorting and detection

Before the finished products are dispatched from the warehouse, sensors can be used to detect whether metal parts are missing, such as the metal rings of mobile phone cameras and the metal contacts of battery covers, and in combination with the vision system, achieve efficient sorting.

Why choose Lanbao non-attenuation sensors?

When traditional proximity switches are exposed to different metal materials, the detection distance may change, which can easily lead to misjudgment or missed detection. The Lanbao non-attenuation sensor, through optimizing the electromagnetic induction design, achieves equidistant detection of all metal materials, significantly enhancing detection reliability and system stability.

Today, as 3C manufacturing moves towards high precision and high efficiency, Lanbao's non-attenuation sensors, with their stable, reliable and intelligent features, are becoming the "invisible guardians" in the metal parts inspection process. Whether it is feeding materials, assembly or inspection, it is safeguarding the efficient operation of the production line!

Post time: Jul-16-2025