Sensors are the "invisible engineers" of automotive intelligent manufacturing, achieving precise control and intelligent upgrades throughout the entire automotive manufacturing process. Sensors, through real-time data collection, precise defect identification and data feedback, have become the core technology for the digital transformation of automotive manufacturing, helping to achieve zero-defect production, energy efficiency optimization and safety improvement .

一、Conveying link

Conveying serves as the bridge of the entire automotive manufacturing process and is the prerequisite for ensuring the smooth implementation of production in the entire workshop.

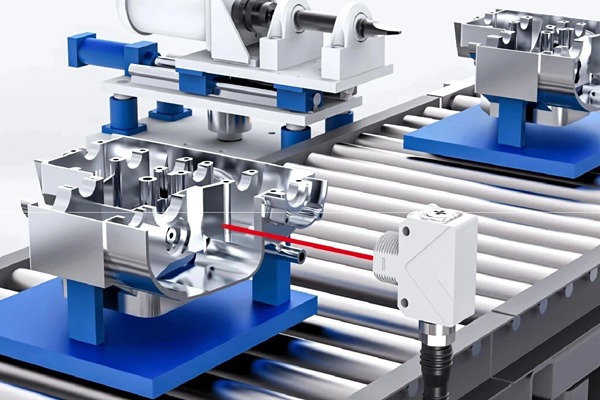

Workpiece in place/counting inspection

The Lanbao PSR-TM20 series through-beam photoelectric sensor plays a crucial role in the in-place and counting detection of automotive parts. Its non-contact detection, high precision and fast response features make it an indispensable component in modern automotive manufacturing.

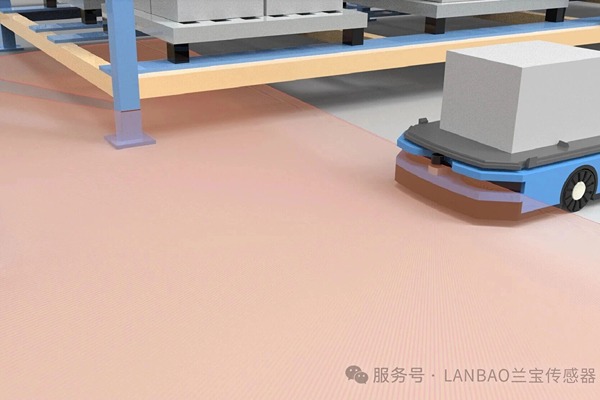

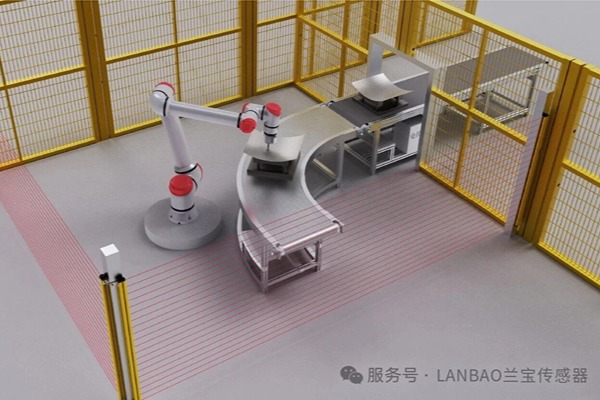

Spare parts delivery

The management of Lanbao PDL lidar is usually installed around the AGV body. By detecting obstacles in real time, it controls the deceleration or stop of the AGV to ensure operational safety .

Skid and vehicle body identification

The Lanbao LE40 series inductive sensors are widely used in accumulation chain conveyor lines. They achieve track separation control by detecting the position status of skids and vehicle bodies. They can be flexibly installed in limited Spaces and reduce interference through a metal-free area design .

The Lanbao MH measurement light curtain sensor can reliably identify different vehicle body types, preventing long downtime or collisions when moving the vehicle body from the skid to the suspension system.

二、Cutting and welding assembly process

Welding is a crucial step in the manufacturing of complete vehicles. In processes such as spot welding, laser welding, positioning welding and bonding, Lanbao sensors and control equipment play a significant role.

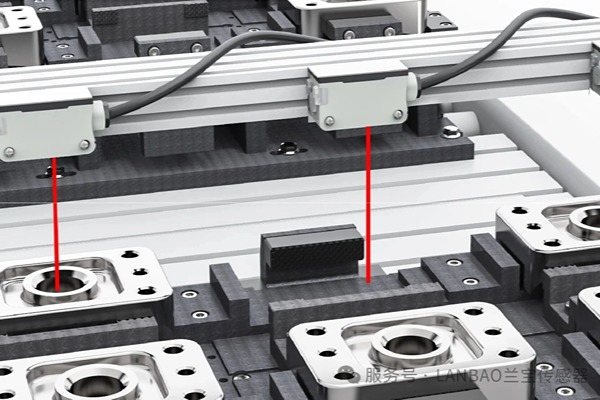

Door assembly gap/weld seam inspection

The Lanbao 3D vision sensor detects the assembly gap between the car door and the body through 3D scanning technology to ensure the accuracy of the hinge installation hole position. The PHM6000 series 3D laser line scan sensor actively projects laser and captures stripe images to identify the position and shape features of weld seams in real time, guiding the welding torch to precisely align.

The Lanbao LR30 series welding immune inductance sensor can resist strong magnetic interference during the welding process, prevent slag adhesion (with PTFE coating), stably detect the position of the car door, reduce welding defects , and achieve an IP67 protection level with a sensor attenuation coefficient of approximately 1.

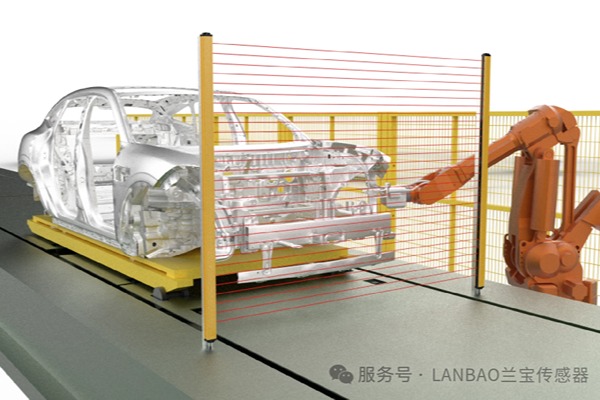

Welding entry

The Lanbao SFS series safety light curtain forms a protective net by emitting infrared light through the projector. When the welding entrance area is blocked by personnel limbs, tools, etc., the light receiver will immediately trigger a signal, cut off the equipment power system within milliseconds, and force the machine to stop to avoid injury . This rapid response capability is particularly suitable for high-risk links such as welding, and can effectively prevent accidents caused by mistakenly entering dangerous areas.

三、Painting process

The painting process is one of the most technology-intensive techniques in automotive manufacturing. Its functions cover protection, decoration, functional identification and environmental innovation , directly affecting the lifespan, aesthetics, safety and market value of automobiles.

Part identification recognition

During the painting process, it is necessary to ensure that the model and batch of the parts match the vehicle. The Lanbao PID series intelligent code reader can quickly read the surface QR code/barcode, avoiding the problems of wrong installation and missed installation.

Industrial cleaning liquid level monitoring

Before painting, the vehicle body or components must be thoroughly cleaned to remove oil stains, rust, oxide scale and other impurities, ensuring the surface cleanliness. The Lanbao CR18XT liquid level sensor measures the liquid level height by detecting changes in capacitance, and can continuously and stably monitor the liquid level of the cleaning solution, providing crucial data support for the production system.

四、Final assembly stage

The final assembly stage in automobile manufacturing is a crucial phase where components such as the body, chassis, powertrain, interior, and exterior are assembled into a complete vehicle, directly determining the final quality of the car.

Automobile assembly

In automotive assembly lines, PSE photoelectric sensors can detect whether parts on the machine are in place or missing. For black components with strong light absorption (such as automotive interiors), the PSE-C red light TOF type photoelectric sensor can stably detect high-brightness and high-reflection objects, and also provide a longer detection distance for dark-colored parts. When inspecting car window glass or windshields, the coaxial optical path design of the PSE-G photoelectric sensor can effectively address the issue of excessive permeability of transparent inspection objects.

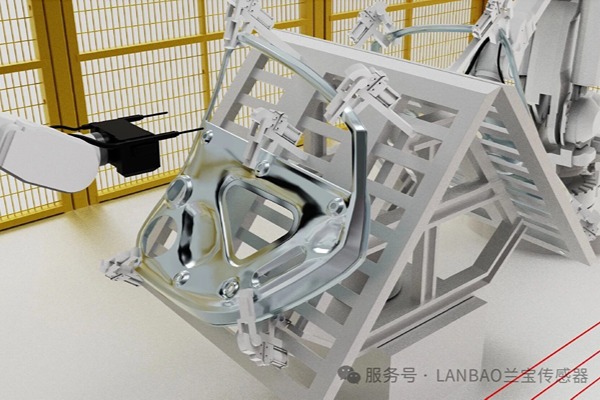

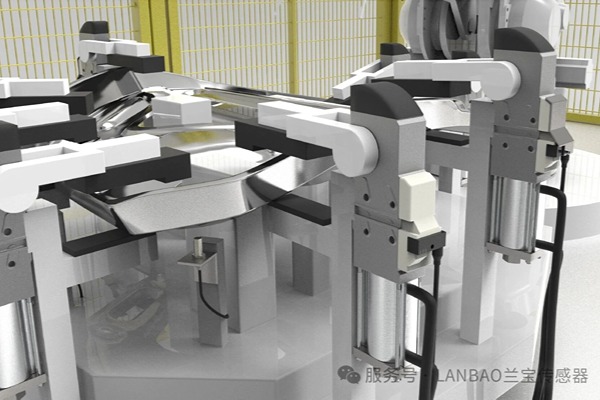

Automobile clamp position detection

The LT18 clamp sensor is mainly used in automotive clamp position detection to monitor the opening and closing status of the clamp in real time, detect whether the car door or other sheet metal parts are in place, and ensure precise control.

Youdaoplaceholder0 sensor technology, as the core support for the intelligence of automotive manufacturing, is reshaping the entire industrial process. From the accurate identification of the presence or absence of workpieces by photoelectric sensors, to the safety light curtains ensuring personnel safety, and then to the visual system completing the detection of vehicle body defects, various sensors build a closed loop of "perception - decision-making - execution" through real-time data feedback.

In the future, multi-sensor collaboration will continue to drive the automotive manufacturing industry towards intelligent production. It not only enhances production efficiency and product consistency but also provides underlying technical support for flexible and green manufacturing, helping the automotive industry maintain its leadership in the wave of intelligence.

Post time: Nov-12-2025