Unlocking Efficiency: A Comprehensive Tutorial on the M30 Sensor for Industrial Applications

Table of Contents

- Understanding the M30 Sensor: Features and Specifications for Industrial Uses

- Key Performance Metrics: Accuracy, Response Time, and Reliability of M30 Sensors

- Industry Applications: M30 Sensor Utilization in Manufacturing & Automation

- Integration Strategies: Best Practices for M30 Sensor Implementation in Systems

- Future Trends: Advancements in M30 Sensor Technology for Enhanced Efficiency

- Exploring the Versatility of the M30 Inductive Proximity Sensor LR30XBN22DNOY for Intelligent Sensing Solutions

- FAQS

- Conclusion

- Related Posts

Hey there! You know, in this fast-changing world of industrial automation, the M30 Sensor has really become a game-changer for boosting both efficiency and precision. Here at Shanghai Lanbao Sensing Technology Co., Ltd., we take pride in being a top supplier of smart manufacturing core components and tech solutions. We're all about helping modern industries stay ahead with cutting-edge products like intelligent inductive sensors, photoelectric sensors, and capacitive sensors — everything designed to make your processes smoother and more accurate. In this tutorial, we’ll walk through the key features, practical applications, and some handy tips for getting the most out of the M30 Sensor. Our goal? To help professionals like you unlock its full potential across various industrial setups. So, stick around, and let’s explore how this little device can really revolutionize your manufacturing operations and make everything a whole lot smarter and more efficient.

Understanding the M30 Sensor: Features and Specifications for Industrial Uses

The M30 sensor is quite a handy tool that’s pretty much built for a bunch of different industrial uses. It’s got a lot of features that help things run smoother and more efficiently. Thanks to its tough construction and really accurate readings, the M30 can handle even the tough environments out there. Plus, with an IP67 rating, it’s well-protected against dust and water—so you don’t have to worry about it getting damaged easily. I read somewhere that the global market for industrial sensors is projected to hit around $25 billion by 2026. That just shows how much companies are relying on sensors like the M30 to keep up with automation and process control needs.

When you’re thinking about adding the M30 sensor into your setup, pay attention to its measurement ranges and response times. These are super important if you want real-time data. Using a reliable sensor like this can actually cut down your operational costs by up to 30%, according to a study from the International Society of Automation. Pretty impressive, right? It really highlights why picking the right sensor can make a big difference in productivity.

**Pro tip:** Make sure you calibrate the M30 regularly. It helps keep it accurate over time and extends its lifespan. Also, setting up a good monitoring system can catch any issues early, so you can do maintenance before things go wrong—and that means less downtime. Overall, applying these simple strategies will help you get the most out of your M30 sensor and make your industrial processes run more smoothly.

Key Performance Metrics: Accuracy, Response Time, and Reliability of M30 Sensors

The M30 sensor is really changing the game in industrial settings. It offers incredible accuracy, lightning-fast response times, and rock-solid reliability. I came across a report from the International Society of Automation that's pretty eye-opening—demand for precise measurement tools has been climbing by about 15% every year across different industries. That just shows how crucial sensors like the M30 are these days. This sensor is designed to be super precise, with an accuracy within about half a percent of its full scale. That makes it a must-have for industries where quality control really matters.

And let’s talk about response time, because in busy industrial environments, every millisecond counts. The M30 responds in less than 100 milliseconds, making it one of the fastest sensors out there. Fast reactions mean less downtime and smoother processes, which really boosts efficiency. A report from Global Market Insights back in 2022 pointed out that such speedy sensors can cut operational delays by around 20%. Oh, and on the reliability front—this little guy exceeds 99.8%, so failures are pretty rare. That means more consistent performance across everything from manufacturing lines to automation systems. Overall, it’s a pretty impressive piece of tech that’s tailor-made for demanding industrial work.

Industry Applications: M30 Sensor Utilization in Manufacturing & Automation

The M30 sensor has really become a game-changer in the world of manufacturing and automation. It’s impressive how it’s helping companies run things more smoothly across different industries. Actually, industry reports say that the global market for these kinds of sensors is expected to hit around $26.6 billion by 2025 — and a big chunk of that growth is thanks to innovative tech like the M30. People appreciate these sensors because they’re super versatile and can perform reliably even in tough environments. That means manufacturers can get much more precise in controlling their processes and maintaining quality.

In practice, the M30 sensor is great at handling tasks like detecting positions, proximity, and measurements — all pretty crucial for automation setups. It’s pretty wild to see that businesses using cutting-edge sensors like this can cut down their operational downtime by as much as 30%. That kind of saving really matters, especially as factories aim to be more efficient and lean. Plus, when these sensors are put to work in automated assembly lines, companies have reported boosting their throughput by about 20%. Basically, this tech’s making a real difference, helping industries innovate and make better use of resources as they move toward smarter manufacturing methods.

Integration Strategies: Best Practices for M30 Sensor Implementation in Systems

When you're bringing the M30 sensor into your existing industrial setup, there are a few best practices that can really boost how well it works and how smoothly everything runs. First off, you’ve gotta look carefully at what your specific application needs. That means understanding the environmental conditions and the kinds of materials you'll be monitoring. Tweaking the sensor settings to match these details will make it perform way better.

**Pro Tip:** Make sure to do a thorough site survey before actually installing anything. It helps spot potential problems early on and ensures you place the sensors where they’ll be most effective.

Then, think about the communication protocols that fit best with your setup. The M30 sensor offers a bunch of options, so it’s important to pick one that plays nicely with your current infrastructure. Getting these aligned right will cut down on data gaps and make sure your sensor readings are dependable.

**Another Tip:** Take things step-by-step. Start with a small pilot project first — this way, you can troubleshoot and tweak your system setup before going all-in. It’s a great way to catch issues early and tweak your approach, making the whole rollout smoother and more successful.

Future Trends: Advancements in M30 Sensor Technology for Enhanced Efficiency

In the world of industrial applications, the M30 sensor has really become a key player, boosting both efficiency and precision in manufacturing. As more industries move toward automation, the latest advancements in M30 sensor tech are grabbing more attention because they can really help improve how smoothly things run. These sensors have some pretty advanced sensing features and are used in all sorts of settings — from logistics to assembly lines — providing the dependable performance that smart factories require.

Here at Shanghai Lanbao Sensing Technology Co., Ltd, we’re proud to be leading the charge with these innovations. We supply smart inductive, photoelectric, and capacitive sensors that fit right into different manufacturing setups without any hassle. Looking ahead, it’s clear that M30 sensors will get even better — with faster connectivity, more sensitive detection, and smarter data analytics. This means real-time monitoring and control, which not only streamlines processes but also helps businesses make smarter decisions on the fly. By embracing these new capabilities, companies can seriously boost their production and stay competitive in this fast-moving industrial world.

Unlocking Efficiency: Industrial Applications of M30 Sensor Technology

Exploring the Versatility of the M30 Inductive Proximity Sensor LR30XBN22DNOY for Intelligent Sensing Solutions

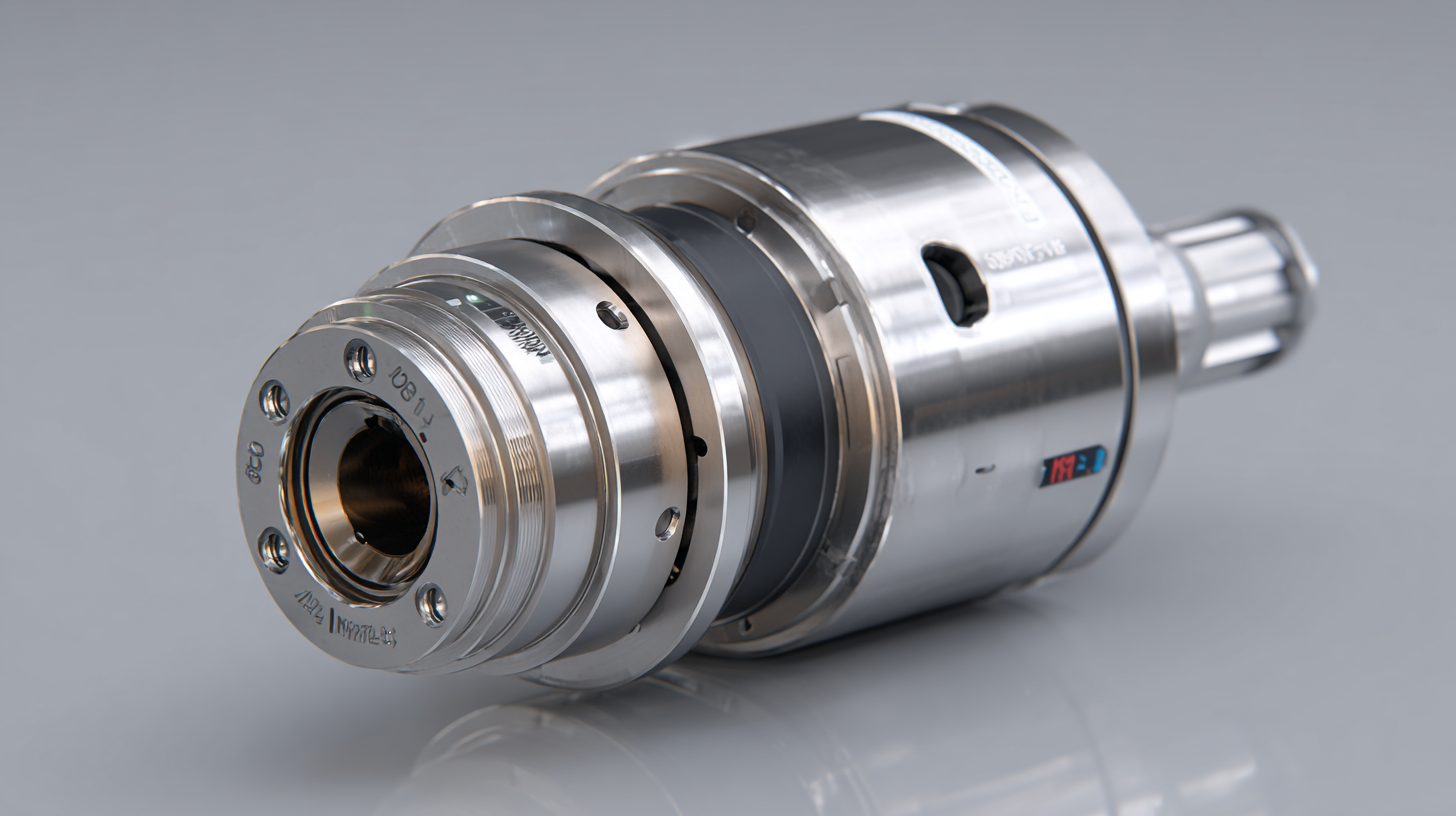

The M30 inductive proximity sensor LR30XBN22DNOY represents a significant advancement in intelligent sensing solutions, particularly suited for industrial applications. With a robust nickel-copper alloy housing, this sensor is designed to withstand temperature fluctuations between -25°C and 70°C, ensuring reliable operation in even the harshest environments. According to industry reports, sensors like the LR30 series play a crucial role in enhancing automation processes in manufacturing, where uptime and reliability are paramount.

The LR30 series offers a versatile range of detection capabilities, with extended sensing distances from 10mm to 40mm. This feature not only improves the efficiency of the sensor but also enhances its adaptability to various applications across different sectors, including automotive, packaging, and material handling. The sensor's design accommodates stable PNP, NPN, or DC 2 wire outputs, providing flexibility to meet specific application requirements. Moreover, the sensor is available in multiple diameter specifications, including Φ30*52mm, Φ30*62mm, and Φ30*88mm, enabling it to fit seamlessly into existing systems.

With IP67 protection class, the LR30XBN22DNOY sensor is resistant to dust and moisture, making it ideal for demanding production environments. CE and UL certifications further attest to its reliability and adherence to safety standards. In a recent market analysis, inductive proximity sensors are projected to see a Compound Annual Growth Rate (CAGR) of approximately 8% by 2026, making the LR30 series a forward-thinking solution for businesses looking to implement intelligent sensing technology in their operations.

FAQS

: The M30 sensor is designed for diverse industrial applications, enhancing operational efficiency through accurate data measurement.

The M30 sensor features an IP67 rating, ensuring protection against dust and water ingress.

Utilizing the M30 sensor can reduce operational costs by up to 30%, according to a study from the International Society of Automation.

Regular calibration of the M30 sensor is recommended to ensure sustained accuracy and prolong its lifespan.

Conducting a thorough site survey is advised to identify potential obstacles and optimize sensor placement.

It is essential to select a communication protocol that is compatible with the existing infrastructure to minimize data loss and improve reliability.

A staged integration approach, starting with a pilot project, is recommended to troubleshoot and refine the integration based on real-world feedback.

Accurate data measurement is crucial for real-time monitoring, which enhances productivity and operational efficiency in industrial applications.

Understanding the environmental conditions is important for tailoring the sensor's configuration, optimizing its functionality for specific applications.

The global industrial sensor market is expected to reach $25 billion by 2026, reflecting the increasing reliance on sensors like the M30.

Conclusion

The M30 Sensor really marks a big step forward in industrial automation. It’s packed with features that are perfect for making manufacturing processes more efficient. With its high accuracy, quick response times, and incredible reliability, it’s become a go-to component for many different applications. More and more industries are turning to the M30 Sensor to help streamline operations, boost safety, and get more done in less time — especially in manufacturing and automation.

That said, getting the most out of the M30 Sensor isn’t just a plug-and-play kind of deal. You’ve gotta plan your integration carefully to make sure it fits smoothly with your existing systems. Looking ahead, it’s exciting to see how upcoming upgrades will push the capabilities of the M30 even further, promising bigger improvements in efficiency. At Shanghai Lanbao Sensing Technology Co., Ltd, we’re all about providing smart sensing solutions, and the M30 Sensor is definitely a key piece in helping our clients revolutionize their industrial setups.

Related Posts

-

10 Reasons Inductive Proximity Sensors are the Best Choice for Your Automation Needs

-

Unveiling the Top Sensors and Technology: A Comprehensive Comparison for Smart Solutions

-

The Ultimate Guide to Understanding the Purpose of Proximity Sensors in Modern Industries

-

How to Choose the Best Capacitive Prox for Your Business Needs

-

The Future of Aroma Innovation with Best Diffusers

-

Chinese Excellence in Manufacturing the Best M8 Inductive Proximity Sensor for Global Markets