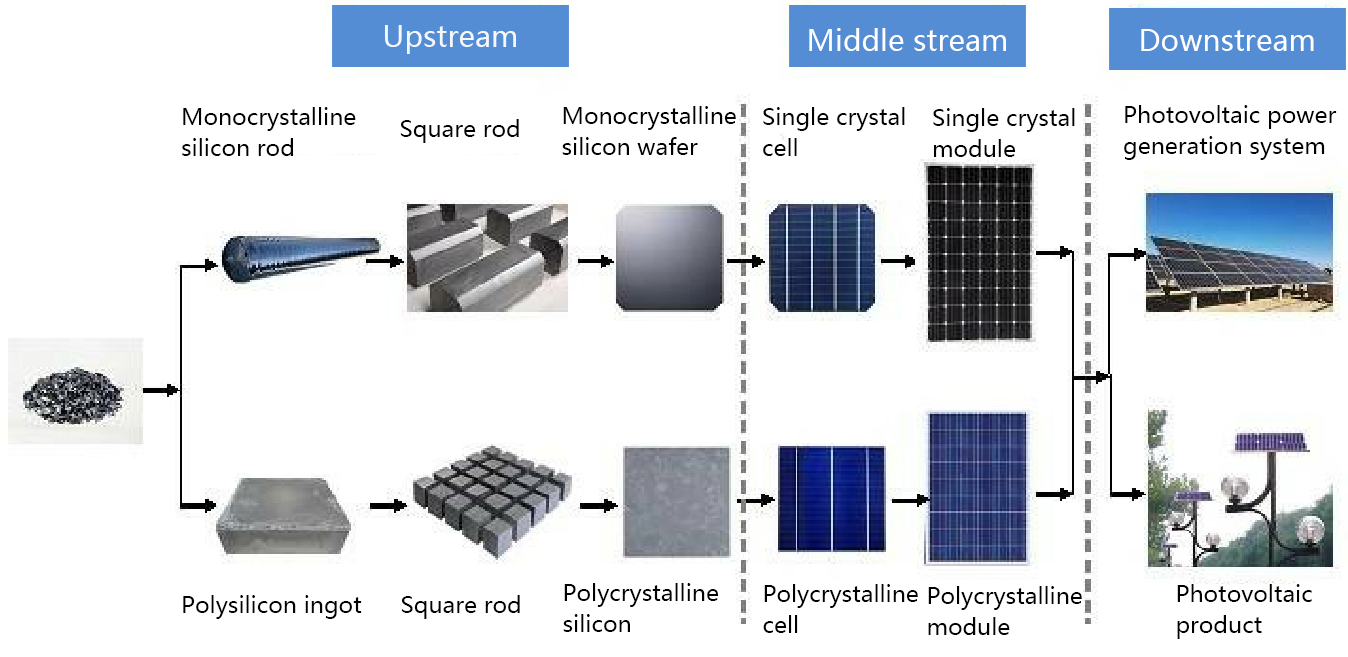

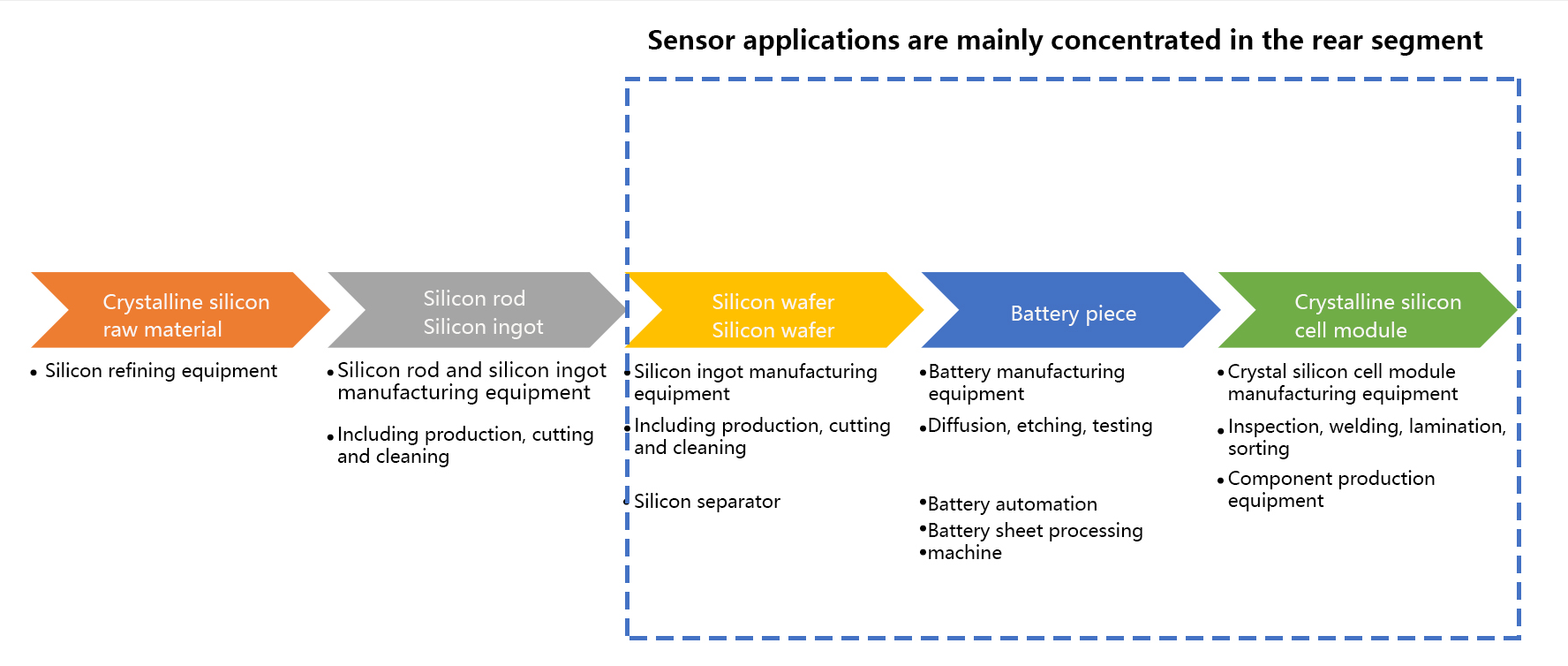

Njengamandla avuselelekayo ahlanzekile, i-photovoltaic idlala indima ebalulekile esakhiweni samandla esizayo. Ngokombono wochungechunge lwezimboni, ukukhiqizwa kwemishini ye-photovoltaic kungafingqwa njengokukhiqizwa kwe-silicon wafer ephezulu, ukukhiqizwa kwe-midstream battery wafer kanye nokukhiqizwa kwe-downstream module. Imishini yokucubungula ehlukene ihilelekile ekuxhumaneni ngakunye kokukhiqiza. Ngokuthuthuka okuqhubekayo kobuchwepheshe bokukhiqiza, izidingo zokunemba zezinqubo zokukhiqiza kanye nemishini yokukhiqiza ehlobene nazo ziyathuthuka njalo. Esigabeni ngasinye sokukhiqiza inqubo, ukusetshenziswa kwemishini yokwenza izinto ngokuzenzakalela enkambisweni yokukhiqiza ye-photovoltaic kudlala indima ebalulekile ekuxhumaniseni isikhathi esidlule nesesikhathi esizayo, ukuthuthukisa ukusebenza kahle kanye nokunciphisa izindleko.

Amabhethri adlala indima ebalulekile kuyo yonke inqubo yokukhiqiza embonini ye-photovoltaic. Igobolondo ngalinye lebhethri eliyisikwele lakhiwe ngegobolondo kanye nepuleti lokumboza eliyingxenye eyinhloko yokuqinisekisa ukuphepha kwebhethri le-lithium. Lizovalwa ngegobolondo leseli lebhethri, ukuphuma kwamandla kwangaphakathi, futhi liqinisekise izingxenye ezibalulekile zokuphepha kweseli lebhethri, elinezidingo eziqinile zokuvalwa kwezingxenye, ukucindezela kwe-valve yokusiza, ukusebenza kukagesi, usayizi kanye nokubukeka.

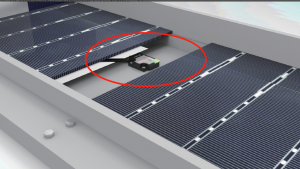

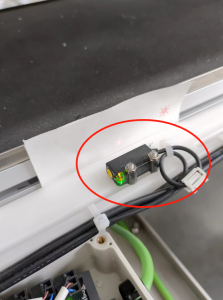

Njengohlelo lokuzwa lwemishini ezenzakalelayo,inzwainezici zokuzwa okunembile, ukufakwa okuguquguqukayo kanye nokuphendula okusheshayo. Indlela yokukhetha inzwa efanelekile ngokwesimo esithile sokusebenza, ukuze kufezwe inhloso yokunciphisa izindleko, ukwanda kokusebenza kahle kanye nokusebenza okuzinzile. Kunezimo zokusebenza ezahlukahlukene enqubweni yokukhiqiza, ukukhanya okuhlukile kwe-ambient, izilinganiso zokukhiqiza ezahlukene kanye nama-wafer e-silicon anemibala ehlukene, njenge-silicon ngemuva kokusika idayimane, i-silicon empunga kanye ne-wafer eluhlaza okwesibhakabhaka ngemuva kokugqoka i-velvet, njll. zombili zinezidingo eziqinile. Inzwa ye-Lanbao inganikeza isisombululo esivuthiwe sokuhlanganiswa okuzenzakalelayo kanye nokukhiqizwa kokuhlolwa kwepuleti lesembozo sebhethri.

Ukuxhumana Kwangemuva Kwe-Emitter Engasebenzi, okungukuthi i-emitter ye-passivation kanye nobuchwepheshe bebhethri ye-passivation yangemuva. Ngokuvamile, ngokusekelwe kumabhethri avamile, ifilimu ye-aluminium oxide ne-silicon nitride ifakwa ngemuva, bese ifilimu ivulwa nge-laser. Njengamanje, ukusebenza kahle kokuguqulwa kwamaseli enqubo ye-PERC kusondele emkhawulweni wethiyori ongu-24%.

Izinzwa zeLanbao zicebile ngezinhlobo futhi zisetshenziswa kabanzi ezigabeni ezahlukahlukene zenqubo yokukhiqizwa kwebhethri le-PERC. Izinzwa zeLanbao azikwazi nje kuphela ukufeza indawo ezinzile nenembile kanye nokutholwa kwendawo, kodwa futhi zihlangabezana nezidingo zokukhiqiza ngesivinini esikhulu, zikhulisa ukusebenza kahle kanye nokunciphisa izindleko zokukhiqiza i-photovoltaic.

Ukusetshenziswa kwezinzwa zomshini weseli

| Isikhundla sokusebenza | Isicelo | Umkhiqizo |

| Ihhavini elicwengayo, ILD | Ukutholwa kwendawo yemoto yensimbi | Inzwa Yokungenisa-Uchungechunge olumelana nokushisa okuphezulu |

| Imishini yokukhiqiza ibhethri | Ukutholwa kwendawo yesikebhe se-silicon wafer, isikebhe se-wafer, isikebhe sesitimela kanye nesikebhe se-graphite | I-Photoelectric Sensoe-Uchungechunge lokubonisa oluhlanganisiwe lwe-PSE |

| (Ukuphrinta isikrini, umugqa wethrekhi, njll.) | ||

| Isiteshi se-Universal - Imodyuli yokunyakaza | Indawo yokuqala | Inzwa ye-Photoelectric-Uchungechunge lwe-sloat slot lwe-PU05M/PU05S |

Ukusetshenziswa kwezinzwa zomshini weseli

| Isikhundla sokusebenza | Isicelo | Umkhiqizo |

| Imishini yokuhlanza | Ukutholwa kwezinga lephayiphi | Inzwa Enamandla-Uchungechunge lwe-CR18 |

| Umugqa wethrekhi | Ukutholwa kobukhona kanye nokutholwa kwamabala kwe-silicon wafer; Ukutholwa kobukhona kwe-wafer carrier | Inzwa yokuphatha amandla-Uchungechunge lwe-CE05, uchungechunge lwe-CE34, Inzwa ye-Photoelectric-Uchungechunge lwe-PSV(ukukhethwa kabusha kwe-convergent), uchungechunge lwe-PSV (ukucindezelwa kwe-backgroud) |

| Ukudluliswa kwethrekhi | Ukutholwa kwendawo yesikebhe se-wafer kanye nendawo yesikebhe se-quartz | Inzwa ye-Cpacitive-Uchungechunge lwe-CR18, inzwa ye-photoelectric-Uchungechunge lwe-PST(ukucindezelwa kwesizinda/ ngokubonakaliswa kwe-beam), uchungechunge lwe-PSE (ngokuboniswa kwe-beam) |

| Inkomishi yokumunca, i-buff ngezansi, ukuphakamisa umshini | Ukutholwa kokuba khona kwama-silicon chips | Inzwa ye-Photoelectric-Uchungechunge lwe-PSV(ukubonakaliswa kokuhlangana), uchungechunge lwe-PSV (ukucindezelwa kwesizinda), Inzwa ye-Cpacitive-Uchungechunge lwe-CR18 |

| Imishini yokukhiqiza ibhethri | Ukutholwa kokuba khona kwesithwali se-wafer kanye nama-silicon chips/ Ukutholwa kwesikhundla se-quartz | Inzwa ye-Photoelectric-Uchungechunge lwe-PSE(ukucindezelwa kwangemuva) |

Isikhathi sokuthunyelwe: Julayi-19-2023