Ukukhiqizwa kwe-semiconductor kumi njengomunye wemikhakha edinga ukunemba kakhulu futhi eyinkimbinkimbi kwezobuchwepheshe embonini yanamuhla yobuchwepheshe obuphezulu. Njengoba izinqubo ze-chip ziqhubekela phambili ku-3nm ngisho nama-node amancane, ukunemba kokulinganisa ubukhulu be-wafer, ukuthamba komphezulu, kanye nobukhulu be-microstructure kunquma ngqo ukukhiqizwa nokusebenza kwe-chip. Kulesi simo, izinzwa zokuhambisa i-laser, ngokusebenza kwazo okungathintani, ukunemba okuphezulu, izikhathi zokuphendula okusheshayo, kanye nokuzinza okuthuthukisiwe, ziye zaba "amehlo okulinganisa" abalulekile kuyo yonke inqubo yokukhiqiza ye-semiconductor.

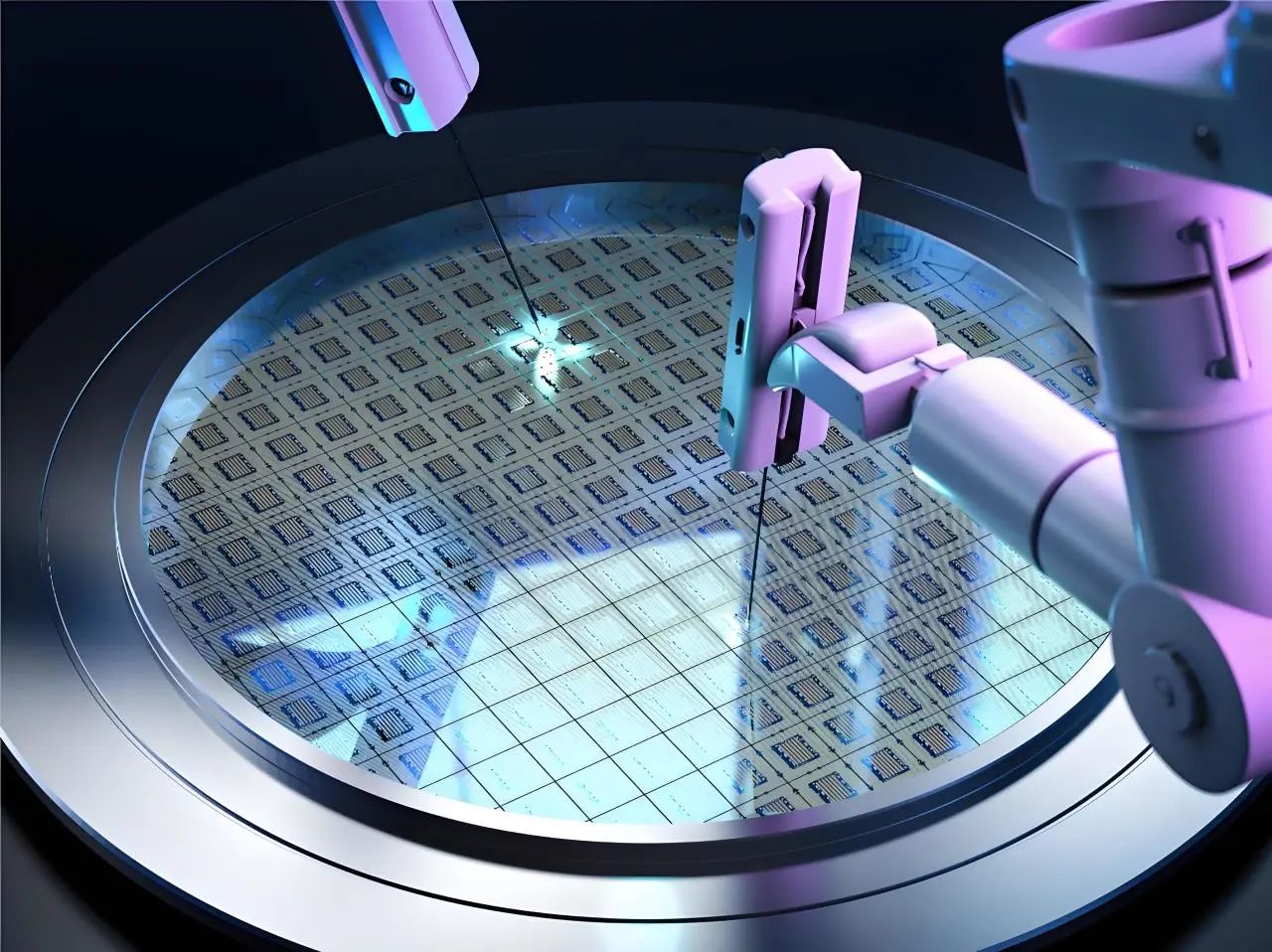

Njengesisekelo esiyinhloko sokwenziwa kwamadivayisi e-semiconductor, ama-wafer adinga ukunemba okukhulu nokuthembeka ngesikhathi sokukhiqiza. Phakathi kwezigaba eziningi ezibucayi zokukhiqiza ama-wafer, ukulinganisa okunembile kokuhamba kubaluleke kakhulu—kuthinta ngqo ukusebenza kwe-chip yokugcina kanye nokukhiqiza. Njengomholi wezinto ezintsha emkhakheni wokuzwa kwezimboni waseShayina, izinzwa zokuhambisa i-laser ze-PDE zochungechunge lwe-Lansensor, ezinesisombululo sezinga le-micron, ama-algorithms ahlakaniphile, kanye nokuthembeka kwezinga lezimboni, ziye zavela njengesixazululo esithandwayo sezinqubo zokukhiqiza ama-wafer.

Izinselele Zokunemba Ekukhiqizeni I-Wafer kanye Nezinzuzo Zezinzwa Zokufuduka Nge-Laser

Ukukhiqizwa kwe-wafer kuhilela uchungechunge lwezinqubo eziyinkimbinkimbi ezifana ne-photolithography, i-etching, i-thin-film deposition, kanye ne-bonding—nganye idinga ukunemba okuqinile ezingeni le-micrometer noma ngisho ne-nanometer. Isibonelo:

-

Ku-photolithography, ukuhambisana okunembile phakathi kwe-photomask ne-wafer kubalulekile ukuqinisekisa ukudluliselwa kwephethini okunembile ebusweni be-wafer.

-

Ngesikhathi sokufakwa kwefilimu encane, ukulawulwa okuqondile kobukhulu befilimu kubalulekile ukuqinisekisa ukusebenza kukagesi kwamadivayisi.

Ngisho nokuphambuka okuncane kakhulu kungaholela ezinkingeni zomkhiqizo noma kwenze inqwaba yama-wafer angasetshenziswa.

Izindlela zokulinganisa zendabuko zemishini zivame ukwehluleka ukuhlangabezana nezidingo ezinjalo ezinembile. Ngaphezu kwalokho, zibeka engcupheni yokulimaza noma ukungcolisa ubuso be-wafer obubuthakathaka, kuyilapho isivinini sazo sokuphendula kancane sizenza zingafaneleki ezidingweni ze-metrology ezisezingeni eliphezulu.

I-LanbaoinzwaIzinzwa Zokufuduka Ze-Laser Zochungechunge lwe-PDEIsixazululo Esifanele Sokufaka Isicelo Se-Wafer

◆Ukulinganisa i-Laser Okungathintani

Isebenzisa ukubonwa kwemisebe ye-laser ezindaweni eziqondiwe, ihlaziya izimpawu ezibonakalisiwe/ezisakazekile ukuze ithole idatha yokufuduka - iqeda ukuthintana ngokomzimba nama-wafer ukuze kuvinjelwe umonakalo wemishini kanye nezingozi zokungcola.

◆Ukunemba kwezinga le-Micron

Ubuchwepheshe be-laser obuthuthukisiwe kanye nama-algorithms okucubungula amasignali aletha ukunemba kanye nesisombululo sokulinganisa ngezinga le-micrometer, okuhlangabezana nezidingo zokunemba okukhulu kwezinqubo zokukhiqiza i-wafer.

◆Impendulo Eshesha Kakhulu (<10ms)

Ivumela ukuqapha kwesikhathi sangempela kokwehluka kokukhiqiza okuguquguqukayo, okuvumela ukutholwa nokulungiswa kokuphambuka okusheshayo ukuthuthukisa ukusebenza kahle kokukhiqiza.

◆Ukuhambisana Okumangalisayo Kwezinto Ezibalulekile

Iyakwazi ukulinganisa izinto ezahlukahlukene kanye nezinhlobo zobuso ngokuzivumelanisa nezimo okunamandla kwemvelo, ifanele izigaba eziningi zenqubo ye-semiconductor.

◆Umklamo Wezimboni Omncane

Isici esiqinile senza kube lula ukuhlanganiswa okungenamthungo kwemishini ezenzakalelayo kanye nezinhlelo zokulawula, okuvumela ukuqapha inqubo okuhlakaniphile kanye nokulungiswa kwe-close-loop.

Izimo ZokusetshenziswaIzinzwa Zokufuduka Ze-Laser Zochungechunge lwe-PDEekucubungulweni kwe-Wafer

Inzwa yeLanbaoIzinzwa Zokufuduka Ze-Laser Zochungechunge lwe-PDEIzicelo Ezibalulekile Ekukhiqizeni Ama-Wafer

Ngokusebenza okuhle kakhulu, izinzwa zokufuduka kwe-laser ze-Lansensor PDE zidlala indima ebalulekile ezinqubweni eziningi zokwenziwa kwe-wafer:

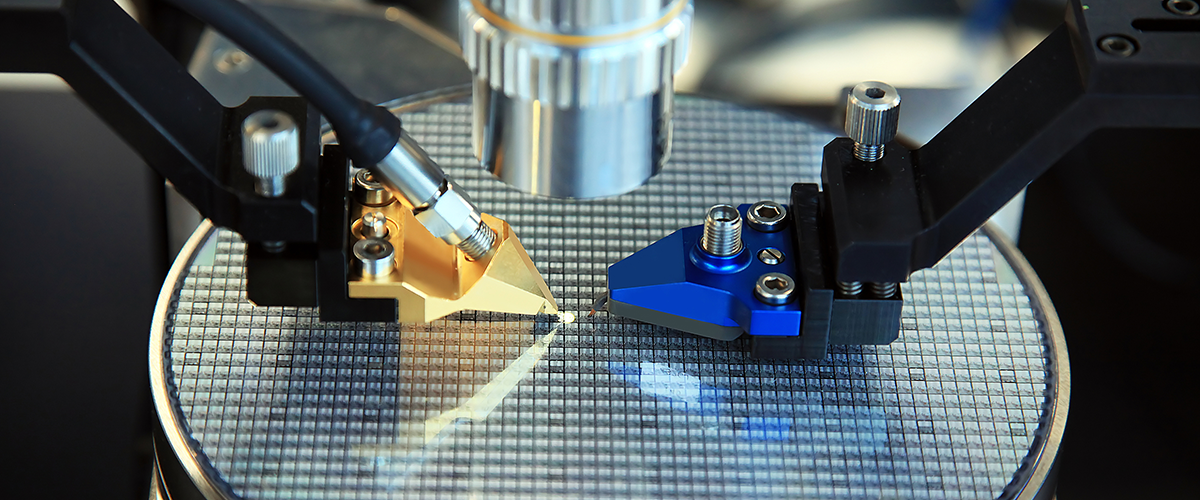

◆Ukulungiswa Nokubekwa Kwe-Wafer

Ngezinqubo ze-photolithography kanye ne-bonding ezidinga ukunemba kwezinga le-micron, izinzwa zethu zilinganisa ngokunembile indawo ye-wafer kanye nama-engeli okuthambekela ukuqinisekisa ukuhambisana okuphelele kwe-mask-to-wafer kanye nokubekwa kwengalo ye-bonding - okuthuthukisa ukunemba kokudluliselwa kwephethini.

◆I-Metology Yobukhulu Be-Wafer

Ukunika amandla ukulinganisa ubukhulu obungathintani nokuqapha ngesikhathi sangempela ngesikhathi sezinqubo zokufaka, ukuqinisekisa ukulawulwa kwekhwalithi yefilimu encane kakhulu.

◆Ukuhlolwa Kokucwebezela Kwe-Wafer

Ukuthola i-wafer warpage kanye nokuguqulwa kwendawo ngesisombululo se-sub-micron ukuvimbela ama-wafer anephutha ukuthi angaqhubeki ehla ngomfula.

◆Ukuqapha Ubukhulu Befilimu Encane

Ukunikeza ukulandelela ukujiya kokufakwa ngesikhathi sangempela ngesikhathi sezinqubo ze-CVD/PVD ukuze kulondolozwe imininingwane eqinile yokusebenza kukagesi.

◆Ukutholwa Okuphelele Kwesici Somphezulu

Ukuhlonza ukungalingani kobuso obuncane (ukuklwebheka, izinhlayiya) ngokusebenzisa imephu yokufuduka enesisombululo esiphezulu, okuthuthukisa kakhulu amazinga okuthola amaphutha.

◆Ukuqapha Isimo Semishini

Ukulandelela ukufuduka kwezingxenye ezibalulekile (izingalo zamarobhothi, ukunyakaza kwesiteji) kanye nokudlidliza komshini ukuze kulungiswe kusengaphambili futhi kuthuthukiswe ukuzinza.

Uchungechunge lwe-PDE lwenzwa yeLanbao alugcini nje ngokuvala izikhala zobuchwepheshe ezibalulekile emakethe yezinzwa zezimboni ezisezingeni eliphezulu zaseShayina kodwa lusungula amazinga amasha omhlaba wonke ngokusebenza kwalo okumangalisayo. Kungakhathaliseki ukuthi kukhulisa amazinga okukhiqiza, ukunciphisa izindleko zokukhiqiza, noma ukusheshisa ukuthuthukiswa kwenqubo yesizukulwane esilandelayo, uchungechunge lwe-PDE luyisikhali sakho sokugcina sokunqoba izinselele zokukhiqiza i-semiconductor ngokunemba!

Isikhathi sokuthunyelwe: Meyi-08-2025