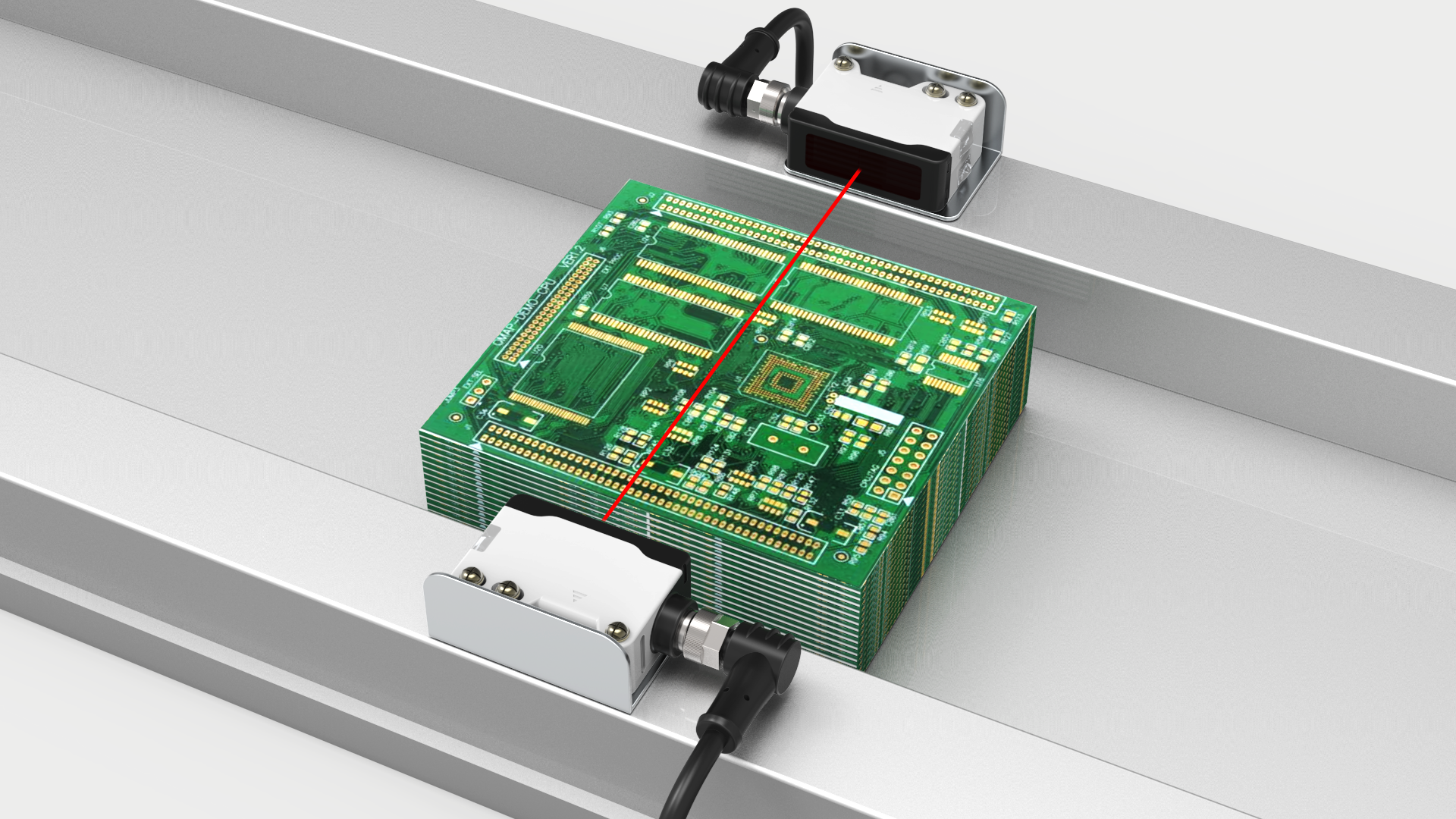

Inzwa ye-PSE through-beam photoelectric ivumela ukuqapha ibanga elifushane, ngokunemba okuphezulu kokuphakama kwe-PCB stack. Inzwa yokuhambisa nge-laser ilinganisa ngokunembile ukuphakama kwezingxenye ze-PCB, ihlonza ngempumelelo izingxenye ezinde kakhulu.

Wake wazibuza ukuthi amabhodi e-PCB, izinhliziyo zamadivayisi kagesi esiwasebenzisa nsuku zonke njengama-smartphone, amakhompyutha, namathebhulethi, enziwa kanjani? Kule nqubo yokukhiqiza enembile neyinkimbinkimbi, "amehlo ahlakaniphile" amabili asebenza buthule, okungukuthi izinzwa zokusondelana kanye nezinzwa ze-photoelectric.

Cabanga ngomugqa wokukhiqiza wesivinini esikhulu lapho izingxenye ezincane eziningi ze-elekthronikhi zidinga ukufakwa ngokunembile emabhodini e-PCB. Noma yiliphi iphutha elincane lingaholela ekwehlulekeni komkhiqizo. Izinzwa eziseduze nezinzwa ze-photoelectric, ezisebenza njenge-"All-Seeing Eye" kanye "ne-All-Hearing Ear" yomugqa wokukhiqiza we-PCB, zingabona ngokunembile indawo, ubuningi, kanye nobukhulu bezingxenye, zinikeze impendulo yesikhathi sangempela emishinini yokukhiqiza, ziqinisekise ukunemba nokusebenza kahle kwayo yonke inqubo yokukhiqiza.

Izinzwa Zokusondelana Nezinzwa Ze-Photoelectric: Amehlo Okukhiqizwa Kwe-PCB

Inzwa yokusondela ifana "nesitholi sebanga" esingakwazi ukuzwa ibanga phakathi kwento nenzwa. Uma into isondela, inzwa ikhipha isignali, itshela idivayisi ukuthi, "Nginesici lapha!"

Inzwa ye-photoelectric ifana kakhulu "nomphenyi wokukhanya," okwazi ukuthola ulwazi olufana nokukhanya okukhulu nombala. Isibonelo, ingasetshenziswa ukuhlola ukuthi amalunga e-solder ku-PCB aphephile noma ukuthi umbala wezingxenye ulungile.

Indima yabo emgqeni wokukhiqiza we-PCB ingaphezu nje "kokubona" kanye "nokulalela"; futhi benza imisebenzi eminingi ebalulekile.

Ukusetshenziswa Kwezinzwa Zokusondela Nezithombe Ekukhiqizweni Kwe-PCB

Ukuhlolwa kwezingxenye

- Ukutholwa Kwengxenye Engekho:

Izinzwa zokusondela zingabona ngokunembile ukuthi izingxenye zifakwe kahle yini, ziqinisekise ubuqotho bebhodi le-PCB. - Ukutholwa Kokuphakama Kwengxenye:

Ngokubona ukuphakama kwezingxenye, ikhwalithi yokunamathisela ingatholakala, kuqinisekiswe ukuthi izingxenye aziphezulu kakhulu futhi aziphansi kakhulu.

Ukuhlolwa kwebhodi le-PCB

-

- Ukulinganisa Ubukhulu:

Izinzwa ze-photoelectric zingalinganisa ngokunembile ubukhulu bamabhodi e-PCB, ziqinisekise ukuthi ziyahlangabezana nezidingo zomklamo. - Ukutholwa Kombala:

Ngokubona izimpawu zombala ebhodini le-PCB, kungatholakala ukuthi izingxenye zifakwe kahle yini. - Ukutholwa Kwamaphutha:

Izinzwa ze-photoelectric zingathola amaphutha emabhodini e-PCB njengokuklwebheka, i-foil yethusi engekho, kanye nezinye izinkinga.

- Ukulinganisa Ubukhulu:

Ukulawulwa Kwenqubo Yokukhiqiza

- Ukubekwa Kwezinto:

Izinzwa zokusondela zingathola ngokunembile indawo yamabhodi e-PCB ukuze acutshungulwe ngokulandelayo. - Ukubalwa Kwezinto:

Izinzwa ze-Photoelectric zingabala amabhodi e-PCB njengoba edlula, ziqinisekise inani elinembile lokukhiqiza.

Ukuhlola Nokulinganisa

-

- Ukuhlolwa Kokuxhumana:

Izinzwa zokusondela zingabona ukuthi amaphedi ebhodini le-PCB afushane noma avulekile. - Ukuhlolwa Kokusebenza:

Izinzwa ze-photoelectric zingasebenza ngokubambisana neminye imishini ukuhlola ukusebenza kwebhodi le-PCB.

- Ukuhlolwa Kokuxhumana:

Imikhiqizo Enconyiwe Ehlobene ne-LANBAO

Ukutholwa Kwesikhundla Sokuphakama Kwe-PCB Stack

-

- I-PSE - Uchungechunge lwe-Photoelectric lwe-Through-Beam Izici:

- Ibanga Lokuthola: 5m, 10m, 20m, 30m

- Umthombo Wokukhanya Okutholakele: Ukukhanya okubomvu, ukukhanya kwe-infrared, i-laser ebomvu

- Usayizi Wendawo: 36mm @ 30m

- Ukukhishwa Kwamandla: 10-30V DC NPN PNP ivame ukuvulwa futhi ivame ukuvalwa

- I-PSE - Uchungechunge lwe-Photoelectric lwe-Through-Beam Izici:

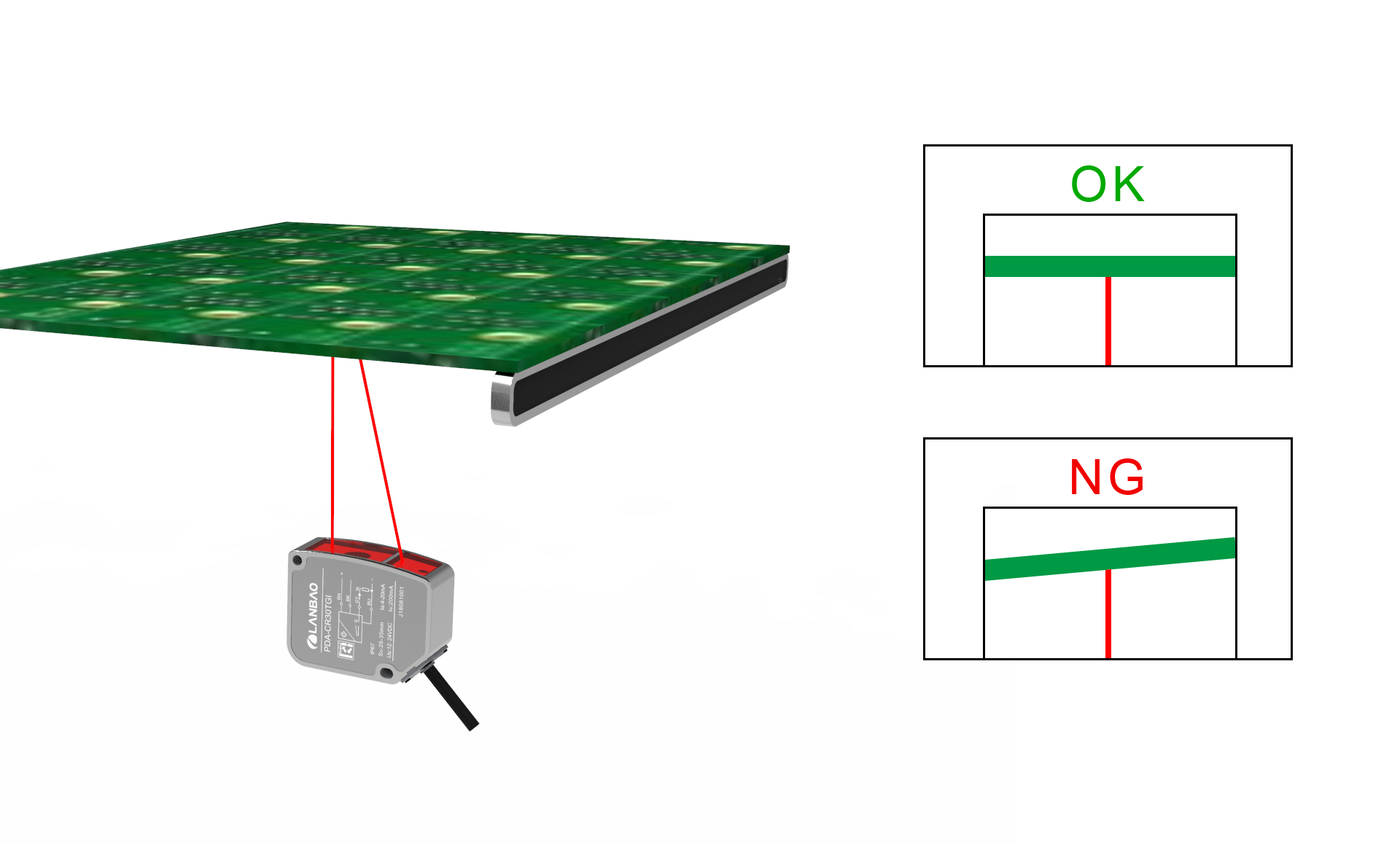

Ukutholwa Kwekhasi Le-Substrate Warpage

Ngokusebenzisa umkhiqizo we-PDA-CR ukukala ukuphakama kwezindawo eziningi ze-PCB substrate, i-warpage inganqunywa ngokuhlola ukuthi amanani okuphakama afana yini.

-

- I-PDA - Uchungechunge Lokufuduka Kwebanga Le-Laser

- Indlu ye-aluminium, eqinile futhi eqinile

- Ukunemba okukhulu kwebanga kufika ku-0.6% FS

- Ibanga lokulinganisa elikhulu, kufika ku-1 imitha

- Ukunemba kokufuduka kufika ku-0.1%, ngosayizi omncane kakhulu wendawo

- I-PDA - Uchungechunge Lokufuduka Kwebanga Le-Laser

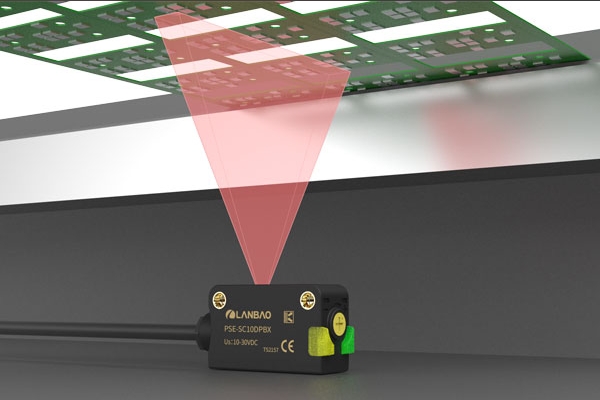

Ukuqashelwa kwe-PCB

Ukuzwa nokuqashelwa okunembile kwama-PCB kusetshenziswa i-PSE - Limited Reflection Series.

Kungani Zidingeka?

- Ukuthuthukisa Ukusebenza Kahle Kokukhiqiza: Ukuzenzakalela ekutholeni nasekulawuleni kunciphisa ukungenelela ngesandla futhi kuthuthukisa ukusebenza kahle kokukhiqiza.

- Ukuqinisekisa Ikhwalithi Yomkhiqizo: Ukutholwa okunembile kuqinisekisa ukuthi imikhiqizo ihlangabezana nezidingo zomklamo futhi yehlisa izinga lokukhubazeka.

- Ukuthuthukisa Ukuvumelana Nezimo Kokukhiqiza: Ukuzivumelanisa nezimo nezinhlobo ezahlukene zokukhiqizwa kwe-PCB kwandisa ukuguquguquka komugqa wokukhiqiza.

Intuthuko Yesikhathi Esizayo

Ngokuthuthuka okuqhubekayo kwezobuchwepheshe, ukusetshenziswa kwezinzwa zokusondelana kanye nezinzwa ze-photoelectric ekukhiqizweni kwe-PCB kuzosabalala kakhulu futhi kujule. Esikhathini esizayo, singalindela ukubona:

- Osayizi Abancane: Izinzwa zizoncishiswa kakhulu futhi zingase zihlanganiswe nezingxenye ezincane ze-elekthronikhi.

- Imisebenzi Ethuthukisiwe: Izinzwa zizokwazi ukubona ububanzi obubanzi bobuningi obubonakalayo, njengokushisa, umswakama, kanye nomfutho womoya.

- Izindleko Eziphansi: Ukwehla kwezindleko zezinzwa kuzothuthukisa ukusetshenziswa kwazo emasimini amaningi.

Izinzwa eziseduze nezinzwa ze-photoelectric, nakuba zincane, zidlala indima ebalulekile ezimpilweni zethu. Zenza imikhiqizo yethu ye-elekthronikhi ibe ngcono futhi iletha lula ekuphileni kwethu kwansuku zonke. Lokhu kuhumusha kugcina incazelo yokuqala kanye nomongo ngenkathi kuqinisekiswa ukucaca nokuhambisana ngesiNgisi.

Isikhathi sokuthunyelwe: Julayi-23-2024