Ukwenziwa kwee-semiconductors kuphakathi kwezona ndawo zifuna ukuchaneka kakhulu kwaye zintsonkothileyo kwezobuchwepheshe kushishino lwanamhlanje lobuchwepheshe obuphezulu. Njengoko iinkqubo zee-chip zisiya kwi-3nm nakwii-nodes ezincinci, ukuchaneka kokulinganisa ubukhulu be-wafer, ukuthamba komphezulu, kunye nobukhulu be-microstructure kumisela ngokuthe ngqo isivuno kunye nokusebenza kwee-chip. Kule meko, ii-sensors ze-laser displacement, ngokusebenza kwazo okungaqhagamshelwanga, ukuchaneka okuphezulu, amaxesha okuphendula ngokukhawuleza, kunye nokuzinza okuphuculweyo, ziye zaba "ngamehlo okulinganisa" ayimfuneko kuyo yonke inkqubo yokwenziwa kwee-semiconductor.

Njengesiseko esiphambili sokwenza izixhobo ze-semiconductor, ii-wafers zifuna ukuchaneka okukhulu kunye nokuthembeka ngexesha lokuvelisa. Phakathi kwamanqanaba amaninzi abalulekileyo okuvelisa ii-wafer, ukulinganisa ngokuchanekileyo ukufuduka kubaluleke kakhulu—kunefuthe ngqo ekusebenzeni kwe-chip yokugqibela kunye nemveliso. Njengenkokeli yokuvelisa izinto ezintsha kwicandelo lokuqonda imboni laseTshayina, ii-PDE series laser displacement sensors zeLansensor, ezinesisombululo se-micron-level, ii-algorithms ezikrelekrele, kunye nokuthembeka kwe-industrial-grade, ziye zavela njengesisombululo esikhethwayo kwiinkqubo zokuvelisa ii-wafer.

Imingeni echanekileyo ekuvelisweni kweWafer kunye neenzuzo zeeSensors zokuFuduka ngeLaser

Ukwenziwa kweewafer kubandakanya uthotho lweenkqubo ezintsonkothileyo ezifana ne-photolithography, i-etching, i-thin-film deposition, kunye ne-bonding—nganye ifuna ukuchaneka okungqongqo kwinqanaba le-micrometer okanye ne-nanometer. Umzekelo:

-

Kwi-photolithography, ukulungelelaniswa ngokuchanekileyo kwe-photomask kunye ne-wafer kubalulekile ukuqinisekisa ukudluliselwa ngokuchanekileyo kwepateni kumphezulu we-wafer.

-

Ngexesha lokufakwa kwefilimu encinci, ulawulo oluchanekileyo lobukhulu befilimu lubalulekile ukuqinisekisa ukusebenza kombane kwezixhobo.

Nokuba kuthe tye kancinci kunokukhokelela kwiingxaki zemveliso okanye kwenze ukuba yonke inqwaba yeewafers ingasetyenziswa.

Iindlela zokulinganisa zemveli zoomatshini zihlala zingaphumeleli ekuhlangabezaneni neemfuno ezinjalo ezichanekileyo. Ngaphezu koko, zibeka emngciphekweni wokonakalisa okanye ukungcolisa umphezulu we-wafer obuthathaka, ngelixa isantya sazo sokuphendula esicothayo sizenza zinganeli kwiimfuno zemetrology eziphambili.

LanbaoinzwaIzinzwa zokuFuduka zeLaser zePDE SeriesIsisombululo esifanelekileyo sezicelo zeWafer

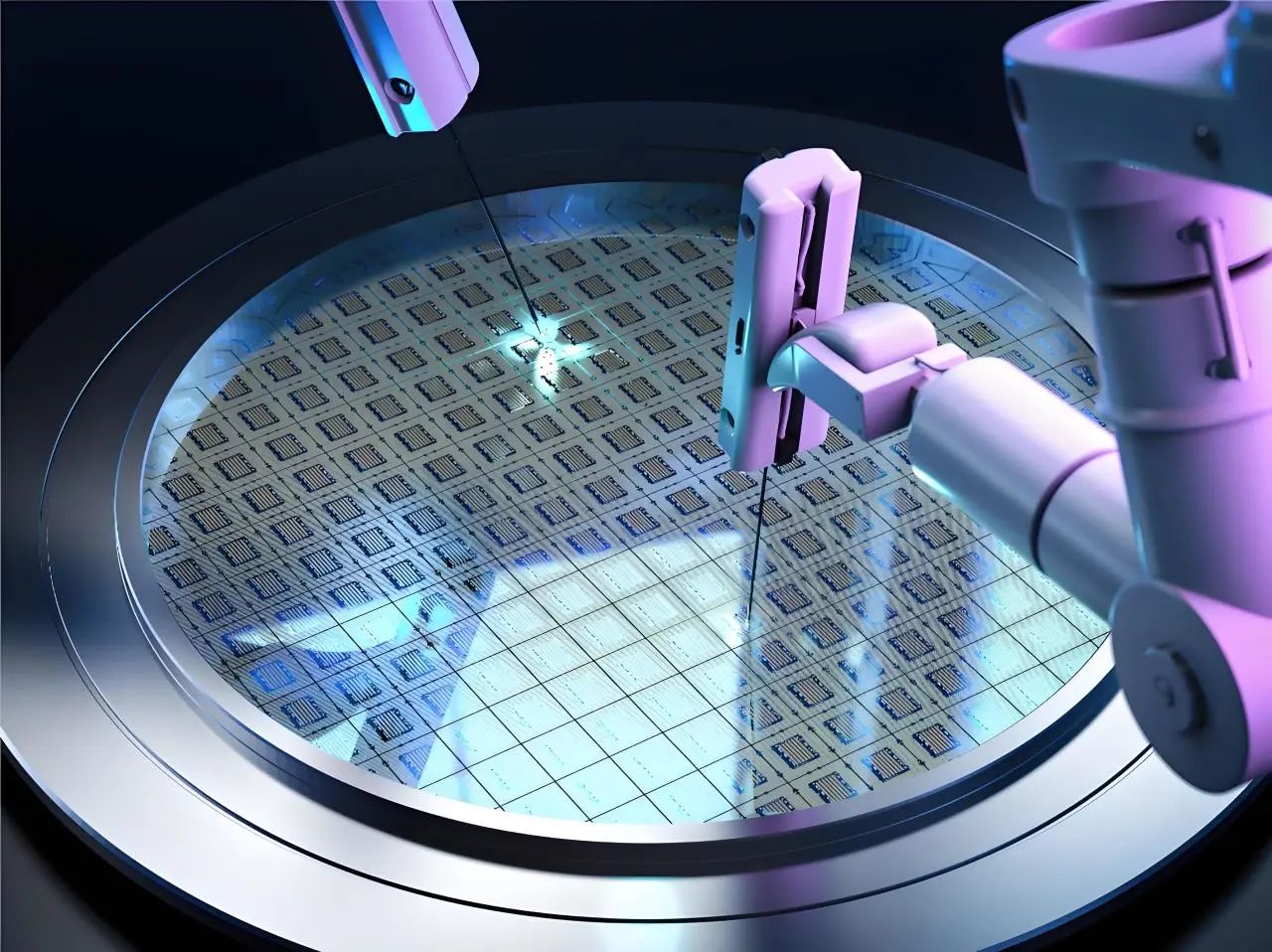

◆Ukulinganisa iLaser engeyiyo eyokuchukumisa

Isebenzisa i-laser beam projection kwiindawo ekujoliswe kuzo, ihlalutya imiqondiso ebonakalisiweyo/esasazekileyo ukuze ifumane idatha yokufuduka - isusa ukudibana ngokomzimba nee-wafers ukuthintela umonakalo woomatshini kunye neengozi zongcoliseko.

◆Ukuchaneka kwenqanaba le-Micron

Itekhnoloji yelaser ephucukileyo kunye nee-algorithms zokucubungula imiqondiso zibonelela ngokuchaneka kunye nesisombululo sokulinganisa isikali se-micrometer, zihlangabezana neemfuno ezichanekileyo kakhulu zeenkqubo zokwenza i-wafer.

◆Impendulo ekhawulezayo kakhulu (<10ms)

Ivumela ukujonga ngexesha langempela utshintsho oluguquguqukayo lwemveliso, ivumela ukufunyanwa nokulungiswa kokuphambuka kwangoko ukuphucula ukusebenza kakuhle kwemveliso.

◆Ukuhambelana okungaqhelekanga kwezinto

Iyakwazi ukulinganisa izinto ezahlukeneyo kunye neentlobo zomphezulu kunye nokuguquguquka okuqinileyo kokusingqongileyo, ifanelekile kwizigaba ezininzi zenkqubo ye-semiconductor.

◆Uyilo oluQhelekileyo lweMizi-mveliso

I-compact form factor inceda ukuhlanganiswa okungenamthungo kwizixhobo ezizenzekelayo kunye neenkqubo zolawulo, okuvumela ukujonga inkqubo ngobuchule kunye nokulungiswa kwe-closed-loop.

Imizekelo yesiceloIzinzwa zokuFuduka zeLaser zePDE SeriesekuHlaziyweni kweWafer

Inzwa yeLanbaoIzinzwa zokuFuduka zeLaser zePDE SeriesIzicelo ezibalulekileyo kwiMveliso yeWafer

Ngokusebenza okugqwesileyo, ii-Lansensor PDE laser displacement sensors zidlala indima ebalulekileyo kwiinkqubo ezininzi zokwenza ii-wafer:

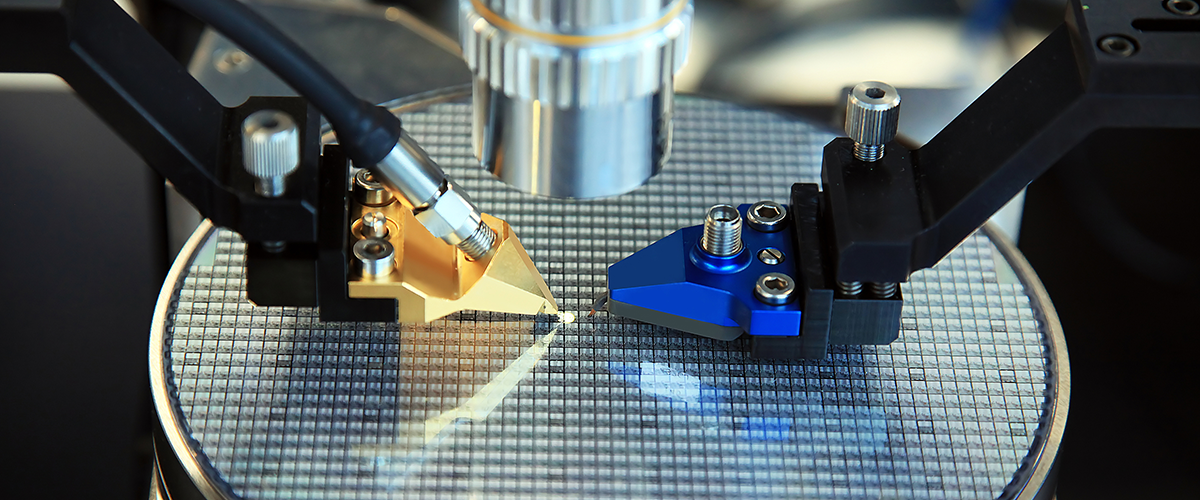

◆Ulungelelwaniso lweWafer kunye nokuBeka

Kwi-photolithography kunye neenkqubo zokubopha ezifuna ukuchaneka kwinqanaba le-micron, ii-sensors zethu zilinganisa ngokuchanekileyo indawo ye-wafer kunye nee-angles zokuthambeka ukuqinisekisa ukulungelelaniswa okugqibeleleyo kwemaski ukuya kwi-wafer kunye nokubekwa kwengalo yokubopha - okuphucula ukuchaneka kokudluliselwa kwepateni.

◆I-Metrology yoButyebi beWafer

Ukuvumela ukulinganiswa kobukhulu obungadibaniyo ngokubekwa esweni ngexesha langempela ngexesha leenkqubo zokubeka, ukuqinisekisa ulawulo olufanelekileyo lomgangatho wefilimu encinci.

◆Uvavanyo lwe-Wafer Flatness

Ukufumanisa i-wafer warpage kunye nokuguqulwa komphezulu ngesisombululo se-sub-micron ukuthintela ii-wafers ezineziphene ukuba zingahambi ziye ezantsi.

◆Ukubeka esweni ukutyeba kwefilimu encinci

Ukubonelela ngokulandelela ubukhulu bokufakwa ngexesha langempela ngexesha leenkqubo ze-CVD/PVD ukugcina iinkcukacha ezingqongqo zokusebenza kombane.

◆Ukufunyanwa kweZiphene eziPhezulu

Ukuchonga izinto ezingaqhelekanga kumphezulu we-micron (imikrwelo, amasuntswana) ngokusebenzisa imephu yokufuduka enesisombululo esiphezulu, nto leyo ephucula kakhulu amazinga okubonwa kweziphene.

◆Ukubeka iliso kwimeko yezixhobo

Ukulandelela ukufuduka kwezinto ezibalulekileyo (iingalo zerobhothi, iintshukumo zesiteji) kunye nokungcangcazela koomatshini ukuze kugcinwe kusengaphambili kwaye kuphuculwe uzinzo.

Uthotho lwe-PDE lwesensor yaseLanbao alupheleli nje ekuvaleni izikhewu ezibalulekileyo zobuchwepheshe kwimarike ye-sensor yemizi-mveliso ephezulu yaseTshayina kodwa luseka iindlela ezintsha zehlabathi ngokusebenza kwayo okugqwesileyo. Nokuba kukunyusa amazinga emveliso, ukunciphisa iindleko zemveliso, okanye ukukhawulezisa uphuhliso lwenkqubo yesizukulwana esilandelayo, uthotho lwe-PDE lumi njengesixhobo sakho sokugqibela sokunqoba imingeni yokuvelisa i-semiconductor echanekileyo!

Ixesha leposi: Meyi-08-2025