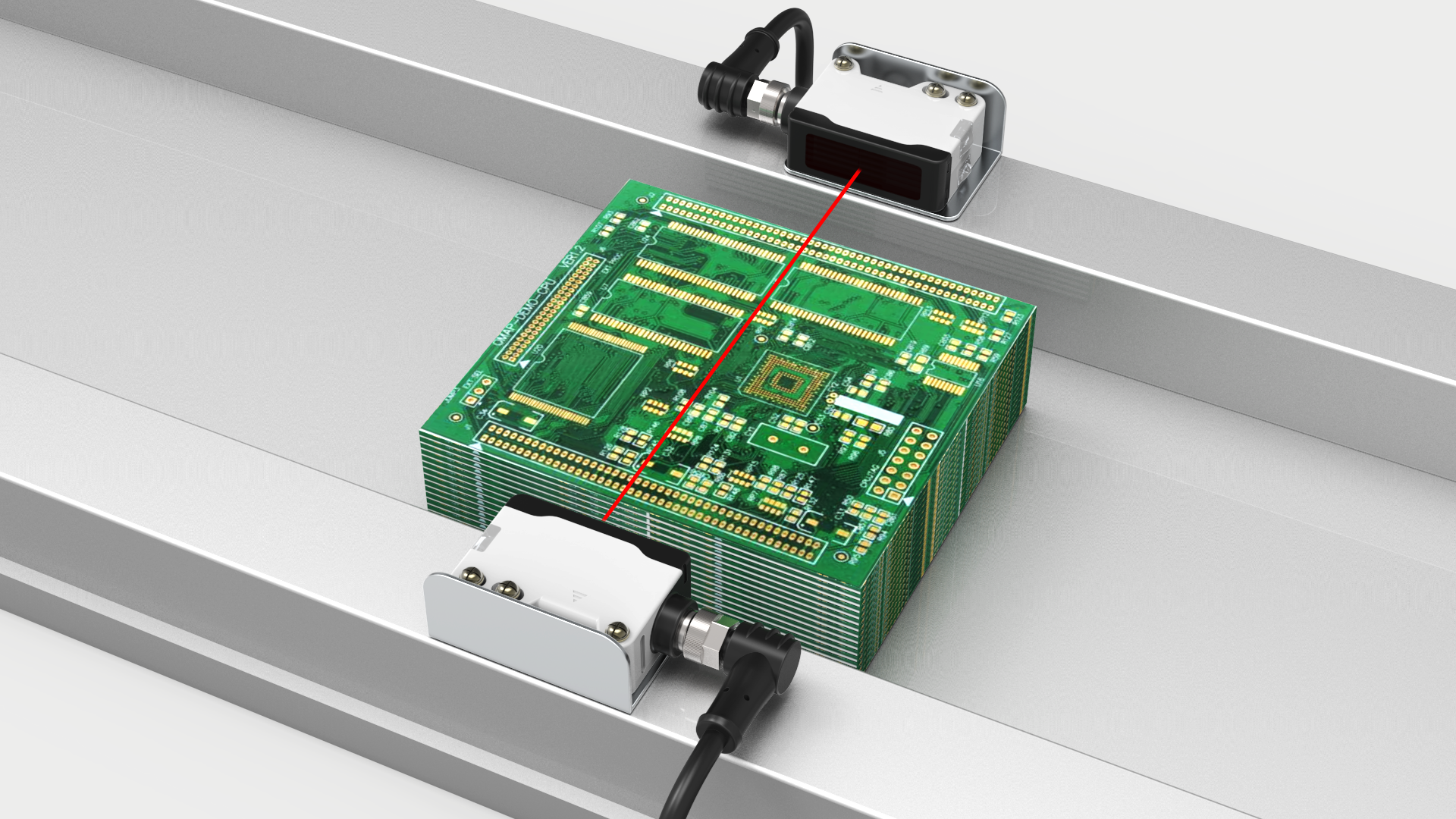

I-PSE through-beam photoelectric sensor ivumela ukujonga ngokuchanekileyo ukuphakama kwe-PCB stack kumgama omfutshane. I-laser displacement sensor ilinganisa ngokuchanekileyo ukuphakama kwe-PCB components, ikwazi ukubona ngokufanelekileyo ii-components ezinde kakhulu.

Ngaba wakha wazibuza ukuba iibhodi zePCB, iintliziyo zezixhobo ze-elektroniki esizisebenzisa imihla ngemihla njengee-smartphones, iikhompyutha, kunye neetablet, zenziwa njani? Kule nkqubo yemveliso echanekileyo neyinkimbinkimbi, "amehlo akrelekrele" asebenza buthule, oko kukuthi, ii-proximity sensors kunye nee-photoelectric sensors.

Khawucinge ngomgca wemveliso okhawulezayo apho izinto ezincinci ezininzi ze-elektroniki kufuneka zibekwe ngokuchanekileyo kwiibhodi ze-PCB. Nayiphi na impazamo encinci inokukhokelela ekusileleni kwemveliso. Izinzwa ezikufutshane kunye nezinzwa ze-photoelectric, ezisebenza njenge-"All-Seeing Eye" kunye ne-"All-Hearing Ear" yomgca wemveliso we-PCB, zinokubona ngokuchanekileyo indawo, ubungakanani, kunye nobukhulu bezinto, zibonelele ngempendulo yexesha langempela kwizixhobo zemveliso, ziqinisekise ukuchaneka nokusebenza kakuhle kwenkqubo yonke yokuvelisa.

Izinzwa ezikufutshane kunye nezinzwa ze-Photoelectric: Amehlo eMveliso ye-PCB

I-proximity sensor ifana "ne-distance detector" ekwaziyo ukubona umgama phakathi kwento kunye ne-sensor. Xa into isondela, i-sensor ikhupha isignali, ixelela isixhobo ukuba, "Ndine-element apha!"

I-sensor ye-photoelectric ifana kakhulu "ne-light detective," ekwaziyo ukubona ulwazi olufana nokukhanya kunye nombala. Umzekelo, ingasetyenziselwa ukujonga ukuba amalungu e-solder kwi-PCB akhuselekile okanye ukuba umbala wezinto ulungile na.

Indima yabo kumgca wemveliso we-PCB ingaphezulu kakhulu kunokuba "babone" kwaye "bamamele"; bakwathatha nemisebenzi emininzi ebalulekileyo.

Ukusetyenziswa kweeSensors zeProximity kunye nePhotoelectric kwiMveliso yePCB

Ukuhlolwa kwecandelo

- Ukufunyanwa kweCandelo elingekhoyo:

Izinzwa zokusondela zinokubona ngokuchanekileyo ukuba izixhobo zifakwe ngokufanelekileyo na, ziqinisekisa ukuthembeka kwebhodi ye-PCB. - Ukufunyanwa kokuphakama kweCandelo:

Ngokubona ukuphakama kwezixhobo, umgangatho wokutywina ungamiselwa, ukuqinisekisa ukuba izixhobo aziphezulu kakhulu kwaye aziphantsi kakhulu.

Ukuhlolwa kwebhodi yePCB

-

- Umlinganiselo Wemilinganiselo:

Izinzwa ze-photoelectric zinokulinganisa ngokuchanekileyo ubukhulu beebhodi ze-PCB, ziqinisekisa ukuba ziyahlangabezana neemfuno zoyilo. - Ukuchonga Umbala:

Ngokubona iimpawu zombala kwibhodi yePCB, kunokuqinisekiswa ukuba izixhobo zifakwe ngokuchanekileyo na. - Ukufunyanwa Kweziphene:

Izinzwa ze-photoelectric zinokubona iziphene kwiibhodi ze-PCB ezifana nemikrwelo, i-copper foil engekhoyo, kunye nezinye iziphene.

- Umlinganiselo Wemilinganiselo:

Ulawulo lweNkqubo yeMveliso

- Ukubekwa kwezinto:

Izinzwa zokusondela zinokubona ngokuchanekileyo indawo yeebhodi ze-PCB ukuze zisetyenzwe kamva. - Ukubala Izinto:

Izinzwa ze-photoelectric zingabala iibhodi ze-PCB njengoko zidlula, ziqinisekisa ubungakanani obuchanekileyo bemveliso.

Uvavanyo kunye noLungiso

-

- Uvavanyo loQhagamshelwano:

Izinzwa zokusondela zinokubona ukuba iiphedi ezikwibhodi yePCB zifutshane okanye zivulekile. - Uvavanyo Lokusebenza:

Izinzwa zefotoelectric zingasebenza kunye nezinye izixhobo ukuvavanya ukusebenza kwebhodi yePCB.

- Uvavanyo loQhagamshelwano:

Iimveliso ezicetyiswayo ezinxulumene neLANBAO

Ukufunyanwa kweSikhundla sokuphakama kweSitayile sePCB

-

- Iimbonakalo zePSE - Through-Beam Photoelectric Series:

- Umgama wokufumanisa: 5m, 10m, 20m, 30m

- Umthombo wokukhanya ochongiweyo: Ukukhanya okubomvu, ukukhanya kwe-infrared, i-laser ebomvu

- Ubungakanani bendawo: 36mm @ 30m

- Isiphumo samandla: 10-30V DC NPN PNP idla ngokuvula kwaye ivalwe ngokuqhelekileyo

- Iimbonakalo zePSE - Through-Beam Photoelectric Series:

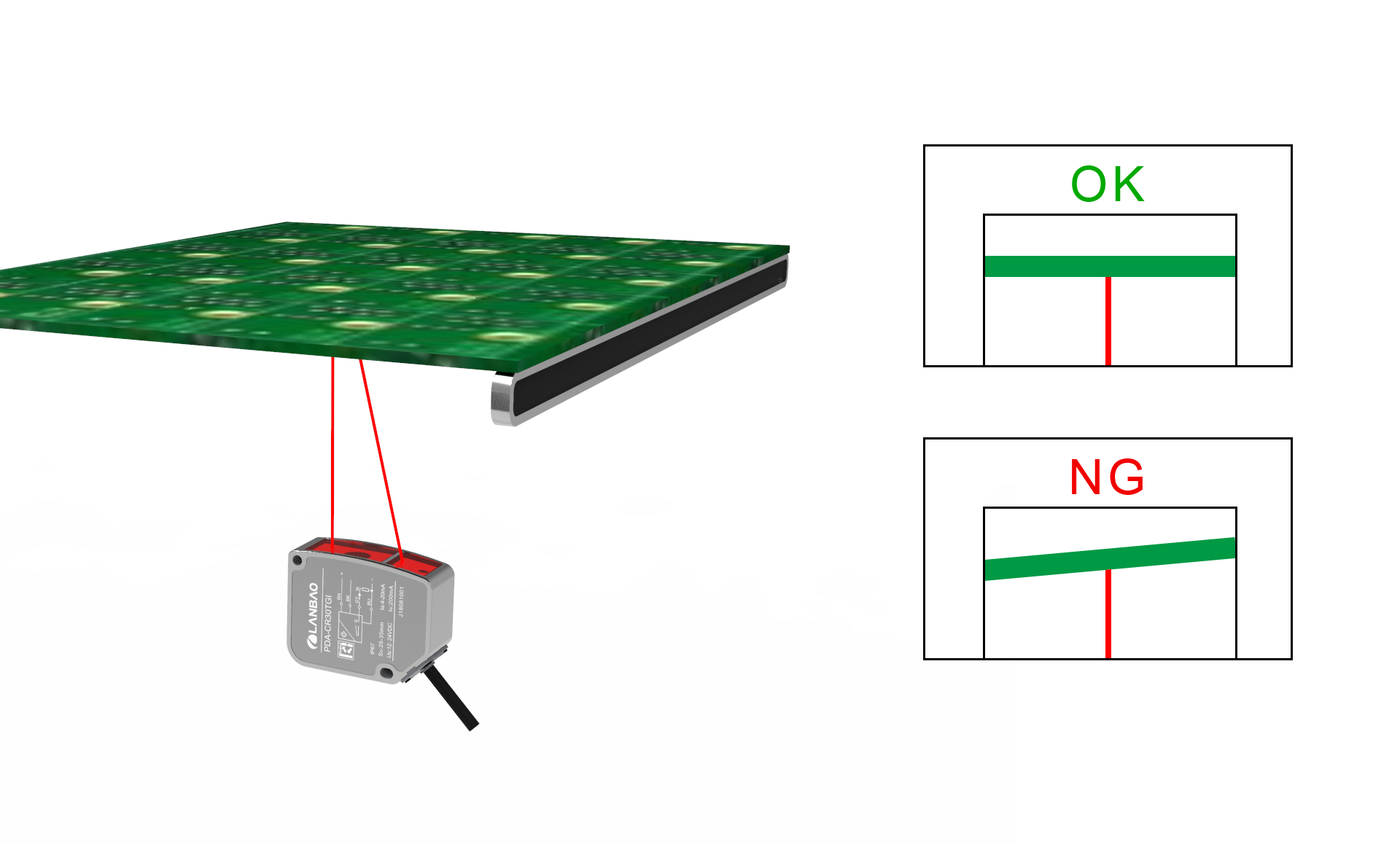

Ukufunyanwa kweSubstrate Warpage

Ngokusebenzisa imveliso yePDA-CR ukulinganisa ukuphakama kweendawo ezininzi ze-PCB substrate, i-warpage inokufunyanwa ngokuvavanya ukuba amaxabiso okuphakama ayafana na.

-

- I-PDA - Uthotho lokuFuduka koMgama ngeLaser

- Indlu ye-aluminium, eqinileyo kwaye ihlala ixesha elide

- Ukuchaneka komgama ophezulu ukuya kuthi ga kwi-0.6% FS

- Uluhlu olukhulu lokulinganisa, ukuya kuthi ga kwi-1 mitha

- Ukuchaneka kokufuduka ukuya kuthi ga kwi-0.1%, kunye nobukhulu bendawo obuncinci kakhulu

- I-PDA - Uthotho lokuFuduka koMgama ngeLaser

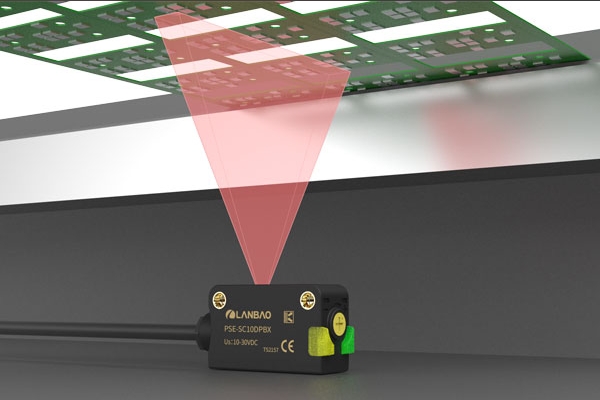

Ukuqatshelwa kwePCB

Ukuva nokuqaphela ngokuchanekileyo ii-PCB kusetyenziswa i-PSE - Limited Reflection Series.

Kutheni Zifuneka?

- Ukuphucula Ukusebenza kakuhle kweMveliso: Ukwenziwa kwezinto ngokuzenzekelayo ekufumaneni nasekulawuleni kunciphisa ukungenelela ngesandla kwaye kuphucula ukusebenza kakuhle kwemveliso.

- Ukuqinisekisa Umgangatho Wemveliso: Ukufunyanwa ngokuchanekileyo kuqinisekisa ukuba iimveliso ziyahlangabezana neemfuno zoyilo kwaye kunciphisa izinga leziphene.

- Ukuphucula Ukuguquguquka Kwemveliso: Ukuzivumelanisa neentlobo ezahlukeneyo zemveliso ye-PCB kwandisa ukuguquguquka komgca wemveliso.

Uphuhliso Lwexesha Elizayo

Ngenxa yokuqhubela phambili kwezobuchwepheshe, ukusetyenziswa kwezinzwa zokusondela kunye nezinzwa ze-photoelectric kwimveliso ye-PCB kuya kusasazeka ngakumbi nangakumbi. Kwixesha elizayo, singalindela ukubona oku kulandelayo:

- Ubungakanani obuncinci: Iisensor ziya kuba zincinci ngakumbi kwaye zinokudityaniswa nezinto ezincinci ze-elektroniki.

- Imisebenzi Ephuculweyo: Iisensor ziya kukwazi ukubona uluhlu olubanzi lobuninzi obubonakalayo, njengobushushu, ukufuma, kunye noxinzelelo lomoya.

- Iindleko eziphantsi: Ukunciphisa iindleko zesensor kuya kuqhuba ukusetyenziswa kwazo kwiindawo ezininzi.

Izinzwa ezikufutshane kunye nezinzwa ze-photoelectric, nangona zincinci, zidlala indima ebalulekileyo ebomini bethu. Zenza iimveliso zethu ze-elektroniki zibe krelekrele kwaye zizisa lula ngakumbi kubomi bethu bemihla ngemihla. Olu guqulelo lugcina intsingiselo yokuqala kunye nomxholo ngelixa luqinisekisa ukucaca kunye nokuhambelana kwisiNgesi.

Ixesha leposi: Julayi-23-2024