Kwicandelo lokuvelisa ii-semiconductor, ukubekwa kwee-chip ezingaqhelekanga yingxaki enkulu yemveliso. Ukubekwa kwee-chips ezingalindelekanga ngexesha lenkqubo yokuvelisa kunokukhokelela ekonakaleni kwezixhobo kunye nokusilela kwenkqubo, kwaye kunokubangela ukulahlwa kweemveliso ezininzi, okubangela ilahleko enkulu kwezoqoqosho kumashishini.

Ngokuphucuka okuqhubekayo kweenkqubo zokwenziwa kwee-semiconductor, iimfuno eziphezulu zibekwa kulawulo lomgangatho ngexesha lokuveliswa. Izinzwa zokufuduka kwelaser, njengeteknoloji yokulinganisa echanekileyo nengenanxibelelwano, zibonelela ngesisombululo esisebenzayo sokufumanisa iingxaki zokubeka ii-chip ngezakhono zazo zokufumanisa ngokukhawuleza nangokuchanekileyo.

Umgaqo wokufumanisa kunye neLogic yokugweba engaqhelekanga

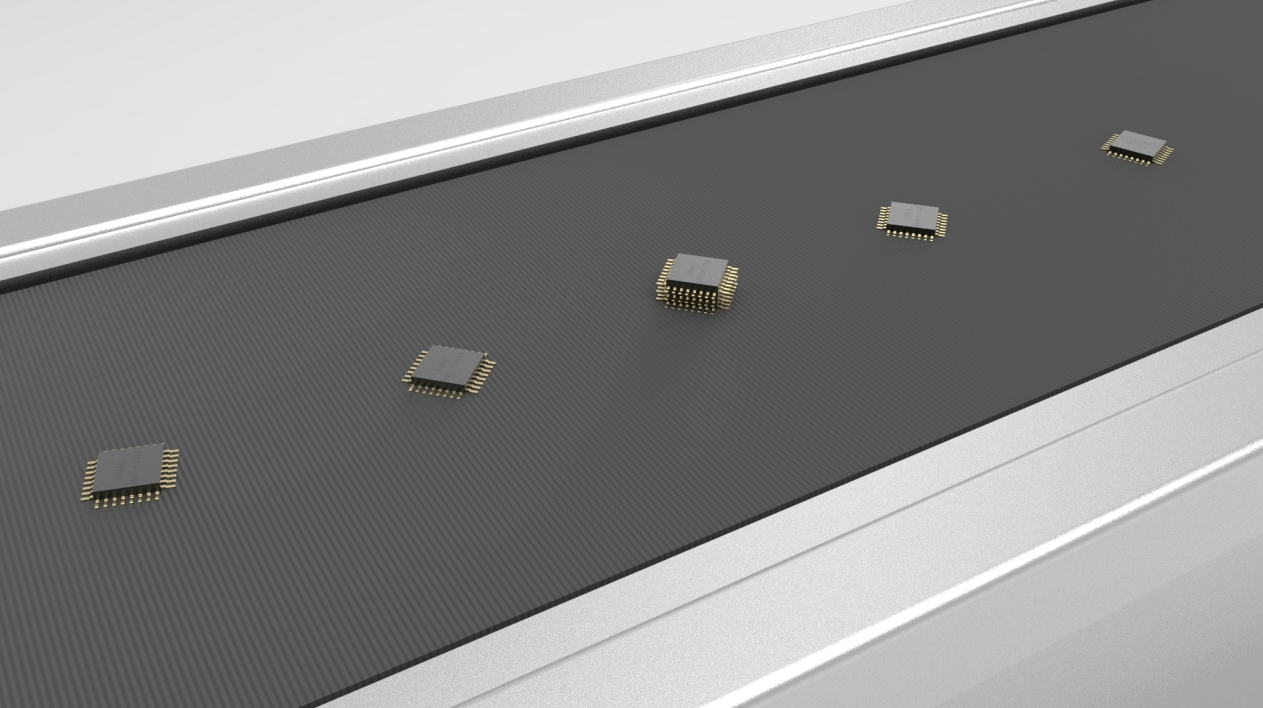

Kwinkqubo yokwenziwa kwee-semiconductor, ii-chips zihlala zibekwe kwiindlela zokuthwala okanye zokuthutha ngendlela enye, ethe tyaba. Ngeli xesha, ukuphakama komphezulu we-chip lixabiso elimiselweyo, ngokubanzi isimbuku sobukhulu be-chip kunye nokuphakama komthwali. Xa ii-chips zibekwe ngempazamo, ukuphakama komphezulu wazo kuya kwanda kakhulu. Olu tshintsho lubonelela ngesiseko esibalulekileyo sokubona ukungaqheleki kwe-stacking.

Ukufunyanwa kokufakwa kweTrack yoThutho

Iindlela zothutho ziyindlela ebalulekileyo yokuhamba kweetshiphusi ngexesha lenkqubo yokwenziwa. Nangona kunjalo, iitshiphusi zinokuqokelelana kwiindlela ngenxa yokutsalwa kwe-electrostatic okanye ukusilela koomatshini ngexesha lothutho, okukhokelela ekuvalekeni kweendlela. Ezi ndlela zokuthintela azinakuphazamisa kuphela ukuhamba kwemveliso kodwa zingonakalisa neetshiphusi.

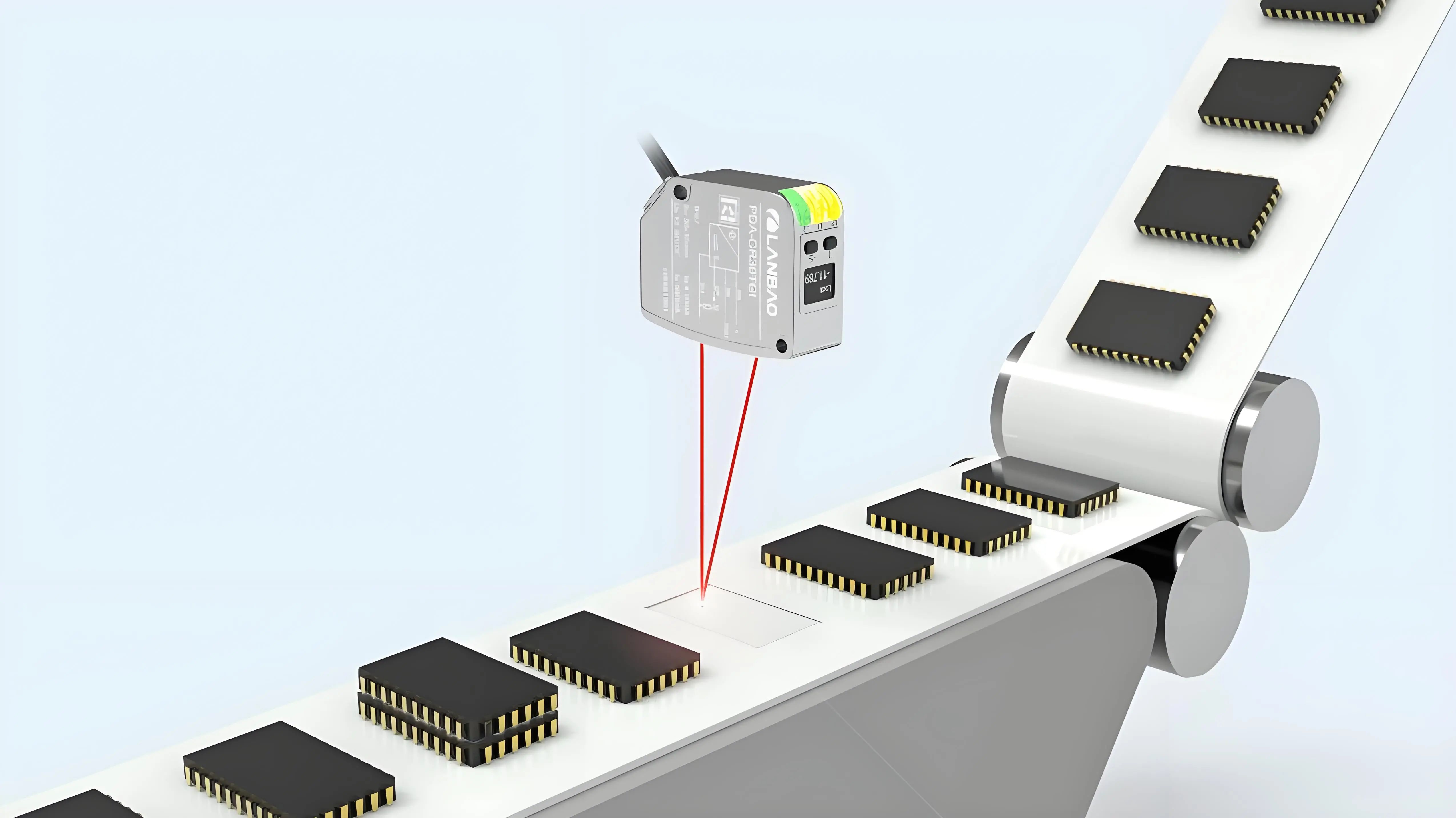

Ukujonga ukuhamba okungapheliyo kwemizila yokuthutha, ii-sensors ze-laser displacement zingafakwa ngaphezulu kwemizila ukuze ziskena ukuphakama kwecandelo elinqamlezileyo lemizila. Ukuba ukuphakama kwendawo ekwindawo ethile akuqhelekanga (umz., kuphezulu okanye kungaphantsi kobukhulu bomaleko omnye weetships), ii-sensors ziya kuyichonga njengento ethintelayo kwaye ziqalise indlela ye-alamu yokwazisa abaqhubi ukuba baphathe ngexesha elifanelekileyo, ukuqinisekisa ukuhamba kakuhle kwemveliso.

Inkqubo yokuFumanisa

Izinzwa zokufuduka kwelaser yeLanbao zilinganisa ngokuchanekileyo ukuphakama kweendawo ekujoliswe kuzo ngokukhupha umqadi welaser, ukufumana isignali ebonakalisiweyo, nokusebenzisa indlela ye-triangulation.

I-sensor ihambelana ngokuthe nkqo nendawo yokubona i-chip, ikhupha i-laser rhoqo kwaye ifumana isignali eboniswayo. Ngexesha lokuthuthwa kwe-chip, i-sensor inokufumana ulwazi lokuphakama komphezulu ngexesha langempela.

I-sensor isebenzisa i-algorithm yangaphakathi ukubala ixabiso lokuphakama komphezulu we-chip ukusuka kwisignali ebonisiweyo efunyenweyo. Ukuze kuhlangatyezwane neemfuno zokudluliselwa kwesantya esiphezulu semigca yemveliso ye-semiconductor, oku kufuna ukuba i-sensor ibe nokuchaneka okuphezulu kunye ne-frequency ephezulu yesampulu.

Kumiselwa uluhlu lokwahluka kokuphakama oluvumelekileyo, oluqhele ukuba yi-±30 µm ukusuka kubude obusisiseko. Ukuba ixabiso elilinganisiweyo lidlula olu luhlu lomlinganiselo, lifunyaniswa ukuba liyinto engaqhelekanga yokubeka izinto. Le ngqiqo yokumisela umda inokwahlula ngokufanelekileyo phakathi kweetships eziqhelekileyo zomaleko omnye kunye neetships ezibekwe izinto.

Xa ifumanisa ukuba kukho into engaqhelekanga eqokelelwayo, inzwa ivuselela i-alamu evakalayo nebonakalayo, kwaye ngaxeshanye ivula ingalo yerobhothi ukususa indawo engaqhelekanga, okanye imise umgca wemveliso ukuthintela ukonakala ngakumbi kwemeko. Le ndlela yokusabela ngokukhawuleza inciphisa ilahleko ezibangelwa kukwahlulwa kwezinto ezingaqhelekanga kakhulu.

Ukufunyanwa kwezinto ezingaqhelekanga kwi-chip stacking ngexesha langempela nangokuchaneka okuphezulu kusetyenziswa ii-laser displacement sensors kunokuphucula kakhulu ukuthembeka kunye nemveliso yemigca ye-semiconductor. Ngophuhliso oluqhubekayo lwetekhnoloji, ii-laser displacement sensors ziya kudlala indima enkulu ngakumbi kwimveliso ye-semiconductor, zibonelela ngenkxaso enamandla kuphuhliso oluzinzileyo lweshishini.

Ixesha leposi: Matshi-25-2025