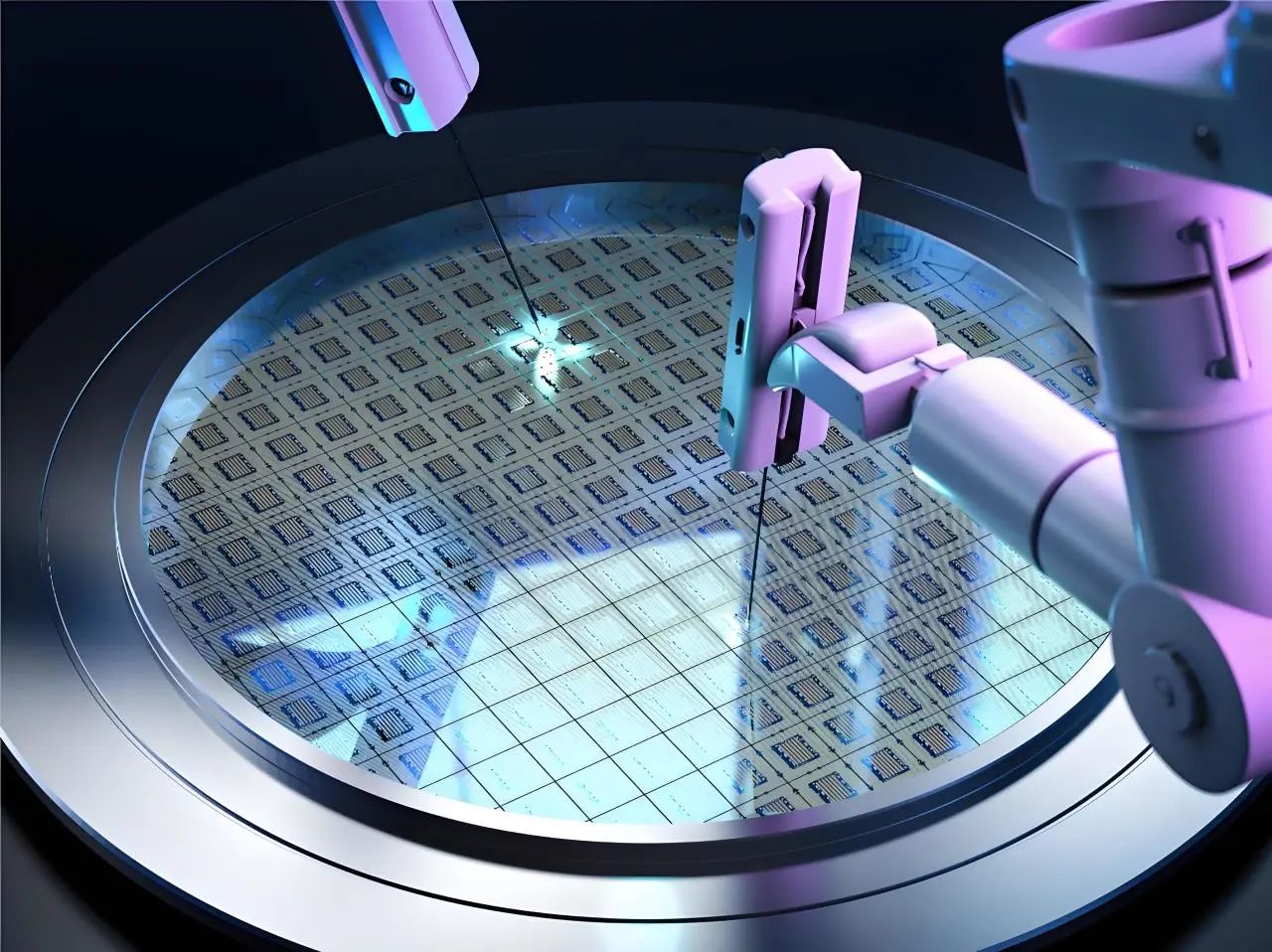

Kupanga ma semiconductors ndi chimodzi mwa madera ovuta kwambiri komanso ovuta kwambiri paukadaulo m'makampani apamwamba amakono. Pamene njira za chip zikupita patsogolo kufika pa 3nm ndi ma node ang'onoang'ono, kulondola kwa miyeso ya makulidwe a wafer, kusalala kwa pamwamba, ndi kukula kwa microstructure kumatsimikiza mwachindunji kuchuluka kwa chip ndi magwiridwe antchito. Pachifukwa ichi, masensa osunthika a laser, omwe amagwira ntchito mosakhudzana, kulondola kwambiri, nthawi yoyankha mwachangu, komanso kukhazikika bwino, akhala "maso oyezera" ofunikira kwambiri panthawi yonse yopanga ma semiconductor.

Monga gawo lalikulu la kupanga zida za semiconductor, ma wafer amafunika kulondola kwambiri komanso kudalirika popanga. Pakati pa magawo ambiri ofunikira popanga ma wafer, kuyeza kolondola kwa kusuntha ndikofunikira kwambiri—kumakhudza mwachindunji magwiridwe antchito ndi phindu la chip yomaliza. Monga mtsogoleri wazinthu zatsopano mu gawo lazowunikira mafakitale ku China, masensa osinthira laser a Lansensor a PDE series, okhala ndi micron-level resolution, ma algorithms anzeru, komanso kudalirika kwa mafakitale, apezeka ngati njira yabwino kwambiri yopangira ma wafer.

Mavuto Olondola Pakupanga Ma Wafer ndi Ubwino wa Ma Laser Displacement Sensors

Kupanga ma wafer kumaphatikizapo njira zingapo zovuta monga photolithography, etching, thin-film deposition, ndi bonding—iliyonse imafuna kulondola kokhwima pa micrometer kapena nanometer level. Mwachitsanzo:

-

Mu photolithography, kulinganiza bwino pakati pa photomask ndi wafer ndikofunikira kwambiri kuti pakhale kusamutsa kolondola kwa mapangidwe pamwamba pa wafer.

-

Pakaikidwa filimu yopyapyala, kuwongolera bwino makulidwe a filimu ndikofunikira kuti zitsimikizire kuti magetsi a zipangizo zikugwira ntchito.

Ngakhale kusintha pang'ono kungayambitse vuto la mankhwala kapena kupangitsa kuti ma wafer ambiri asagwiritsidwe ntchito.

Njira zoyezera zachikhalidwe nthawi zambiri sizimakwaniritsa zofunikira kwambiri. Kuphatikiza apo, zimakhala pachiwopsezo chowononga kapena kuipitsa pamwamba pa wafer wofooka, pomwe liwiro lawo loyankha pang'onopang'ono limapangitsa kuti zisakwanire zofunikira zamakono za metrology.

LabaosensaMasensa Osamutsa Laser a PDE Series: Yankho Labwino Kwambiri la Ma Wafer Applications

◆Kuyeza kwa Laser Kosakhudzana ndi Kukhudza

Amagwiritsa ntchito kuwala kwa laser pamalo omwe akufuna, kusanthula zizindikiro zomwe zawonetsedwa/zobalalika kuti apeze deta yosuntha - kuchotsa kukhudzana ndi ma wafer kuti apewe kuwonongeka kwa makina ndi zoopsa za kuipitsidwa.

◆Kulondola kwa Micron-level

Ukadaulo wapamwamba wa laser ndi ma algorithms opangira zizindikiro amapereka kulondola ndi kutsimikiza kwa muyeso wa micrometer, kukwaniritsa zofunikira kwambiri pakupanga ma wafer.

◆Yankho Lofulumira Kwambiri (<10ms)

Zimathandizira kuyang'anira nthawi yeniyeni kusintha kwa kupanga, zomwe zimathandiza kuzindikira ndi kukonza zolakwika nthawi yomweyo kuti ziwonjezere magwiridwe antchito opanga.

◆Kugwirizana Kwapadera kwa Zinthu

Yokhoza kuyeza zinthu zosiyanasiyana ndi mitundu ya pamwamba yokhala ndi kusinthasintha kwamphamvu kwa chilengedwe, yoyenera magawo angapo a semiconductor processing.

◆Kapangidwe Kakang'ono ka Mafakitale

Chopangidwa ndi mawonekedwe ang'onoang'ono chimathandizira kuphatikiza bwino zida zodziyimira pawokha komanso makina owongolera, zomwe zimathandiza kuyang'anira njira mwanzeru komanso kusintha kosalekeza.

Zochitika Zogwiritsira NtchitoMasensa Osamutsa Laser a PDE Seriesmu Kukonza Ma Wafer

Sensa ya LanbaoMasensa Osamutsa Laser a PDE SeriesNtchito Zofunikira Pakupanga Ma Wafer

Ndi magwiridwe antchito abwino kwambiri, masensa osinthira laser a Lansensor PDE amachita ntchito zofunika kwambiri pakupanga ma wafer angapo:

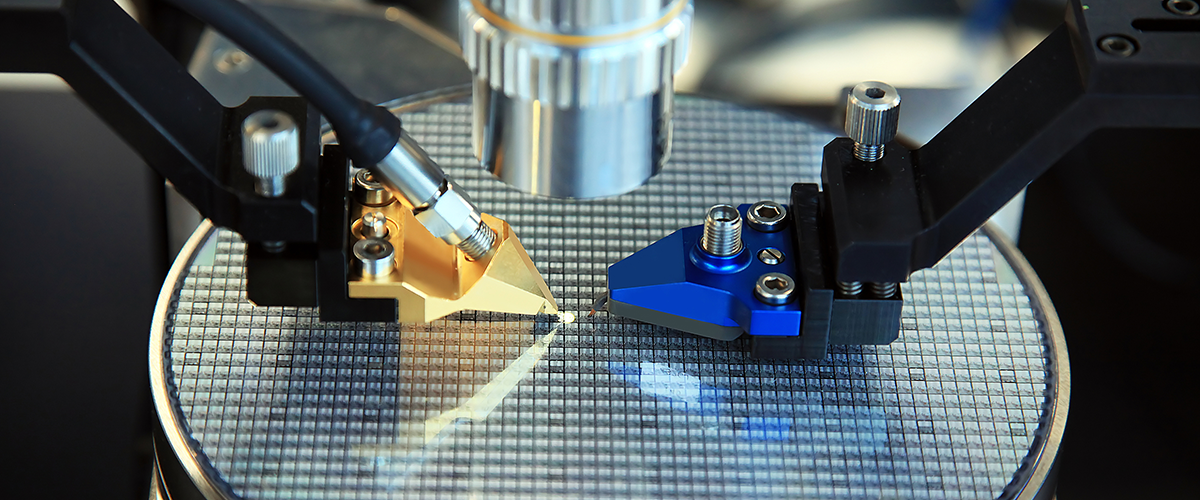

◆Kulinganiza ndi Kuyika Wafer

Pa njira zojambulira zithunzi ndi zolumikizira zomwe zimafuna kulondola kwa micron-level, masensa athu amayesa bwino malo a wafer ndi ma angles opendekera kuti atsimikizire kulumikizana bwino kwa chigoba ndi wafer komanso malo olumikizirana mkono - zomwe zimapangitsa kuti kusamutsa mawonekedwe kukhale kolondola.

◆Kuchuluka kwa Wafer Metrology

Kuthandizira kuyeza makulidwe osakhudzana ndi kukhudzana ndi kuyang'anira nthawi yeniyeni panthawi yoyika zinthu, kuonetsetsa kuti khalidwe la filimu yopyapyala ndi loyenera.

◆Kuyang'anira Kusalala kwa Wafer

Kuzindikira kupotoka kwa wafer ndi kusintha kwa pamwamba ndi resolution ya sub-micron kuti ma wafers olakwika asapitirire pansi pa mtsinje.

◆Kuwunika Kukhuthala kwa Filimu Yoonda

Kupereka njira yowunikira makulidwe a depositi nthawi yeniyeni panthawi ya CVD/PVD kuti zisunge zofunikira zamagetsi.

◆Kuzindikira Kwabwino kwa Ziphuphu Pamwamba

Kuzindikira zolakwika za pamwamba pa micron-scale (kukanda, tinthu tating'onoting'ono) kudzera mu mapu osunthika apamwamba, zomwe zimathandizira kwambiri kuzindikira zolakwika.

◆Kuwunika Mkhalidwe wa Zipangizo

Kutsata kusuntha kwa zigawo zofunika kwambiri (manja a robot, mayendedwe a siteji) ndi kugwedezeka kwa makina kuti zikonzedwe bwino komanso kuti zikhale bwino.

Mndandanda wa PDE wa Lanbao sensor sumangolumikiza mipata yofunika kwambiri yaukadaulo pamsika wapamwamba wa masensa aku China komanso umakhazikitsa miyezo yatsopano yapadziko lonse lapansi ndi magwiridwe ake abwino kwambiri. Kaya kukweza mitengo yokolola, kuchepetsa ndalama zopangira, kapena kufulumizitsa chitukuko cha njira zatsopano, mndandanda wa PDE ndi chida chanu chachikulu chothana ndi zovuta zopangira semiconductor molondola!

Nthawi yotumizira: Meyi-08-2025