Tlhahiso ea li-semiconductor e eme e le e 'ngoe ea masimo a hlokang ho nepahala le ho rarahana ka ho fetisisa indastering ea theknoloji e phahameng ea kajeno. Ha lits'ebetso tsa chip li ntse li tsoela pele ho ea ho 3nm le li-node tse nyane, ho nepahala ha litekanyo bakeng sa botenya ba wafer, ho batalla ha bokaholimo, le litekanyo tsa sebopeho sa microstructure ho khetholla ka ho toba chai le ts'ebetso ea chip. Moelelong ona, li-sensor tsa ho falla ha laser, ka ts'ebetso ea tsona e sa amaneng, ho nepahala ho phahameng, linako tsa karabelo tse potlakileng, le botsitso bo ntlafalitsoeng, li fetohile "mahlo a tekanyo" a bohlokoa ho pholletsa le ts'ebetso ea tlhahiso ea semiconductor.

Jwalo ka karolo ya mantlha ya tlhahiso ya disebediswa tsa semiconductor, di-wafer di hloka ho nepahala ho feteletseng le ho tshepahala nakong ya tlhahiso. Har'a mehato e mengata ya bohlokwa ya tlhahiso ya di-wafer, tekanyo e nepahetseng ya ho falla ke ya bohlokwa haholo—e ama ka ho toba tshebetso le tlhahiso ya chip ya ho qetela. Jwalo ka moetapele wa boqapi lefapheng la kutlo ya diindasteri la China, di-sensor tsa ho falla ha laser tsa letoto la PDE tsa Lansensor, tse nang le qeto ya boemo ba micron, di-algorithms tse bohlale, le ho tshepahala ha maemo a indasteri, di hlahile e le tharollo e kgethwang bakeng sa ditshebetso tsa tlhahiso ya di-wafer.

Liphephetso tse Nepahetseng Tlhahisong ea Wafer le Melemo ea Li-sensor tsa ho Falla ha Laser

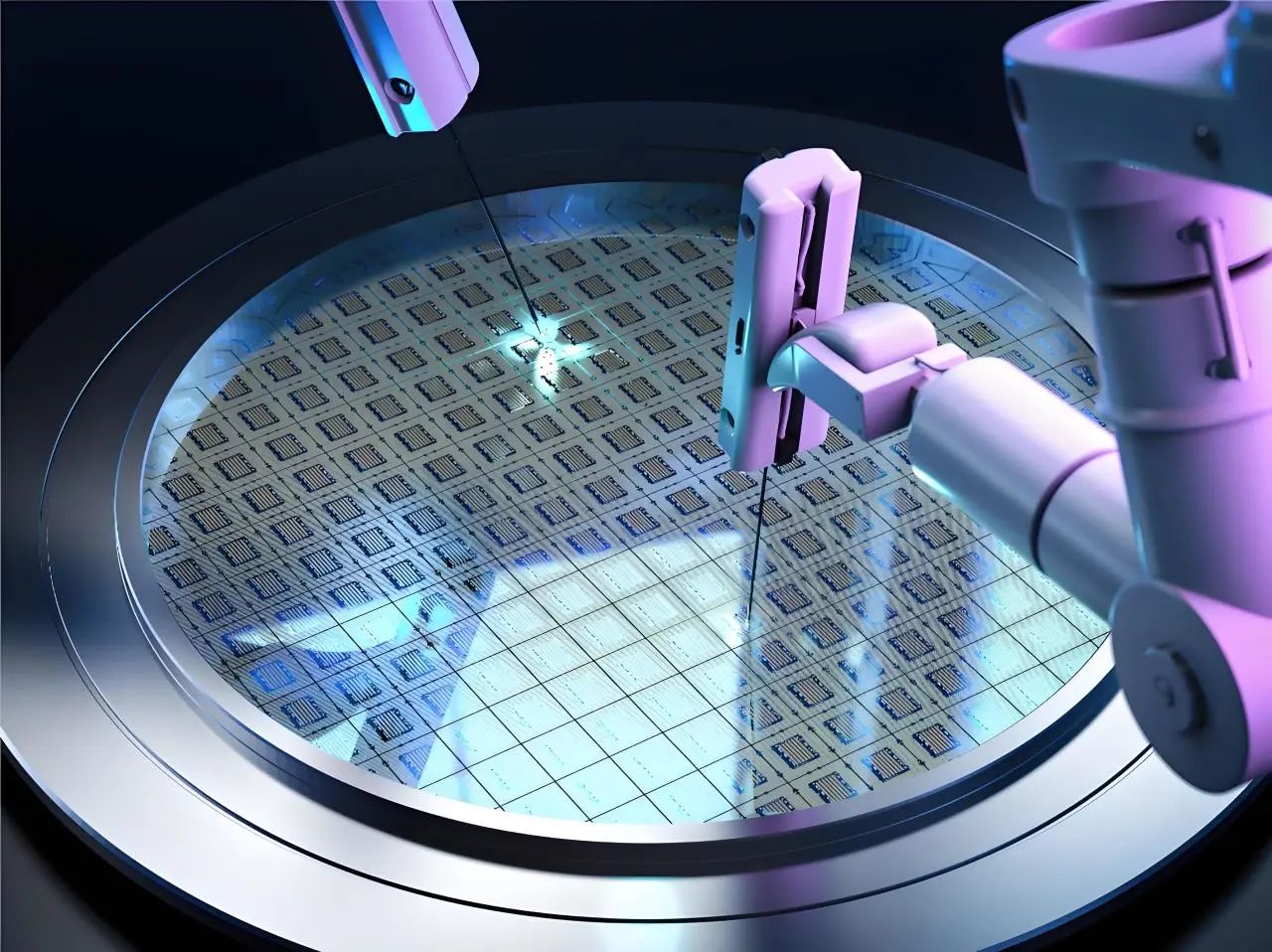

Tlhahiso ea li-wafer e kenyelletsa letoto la lits'ebetso tse rarahaneng tse kang photolithography, etching, thin-film deposition, le ho kopanya—e 'ngoe le e 'ngoe e hloka ho nepahala ho tiileng boemong ba micrometer kapa esita le nanometer. Mohlala:

-

Ho photolithography, ho hokahanya hantle pakeng tsa photomask le wafer ho bohlokoa ho netefatsa phetiso e nepahetseng ea paterone holim'a wafer.

-

Nakong ea ho kenngoa ha filimi e tšesaane, taolo e nepahetseng ea botenya ba filimi ea hlokahala ho netefatsa ts'ebetso ea motlakase ea lisebelisoa.

Esita le ho kheloha ho honyenyane ho ka lebisa bofokoding ba sehlahisoa kapa ha etsa hore sehlopha sohle sa li-wafer se se ke sa sebelisoa.

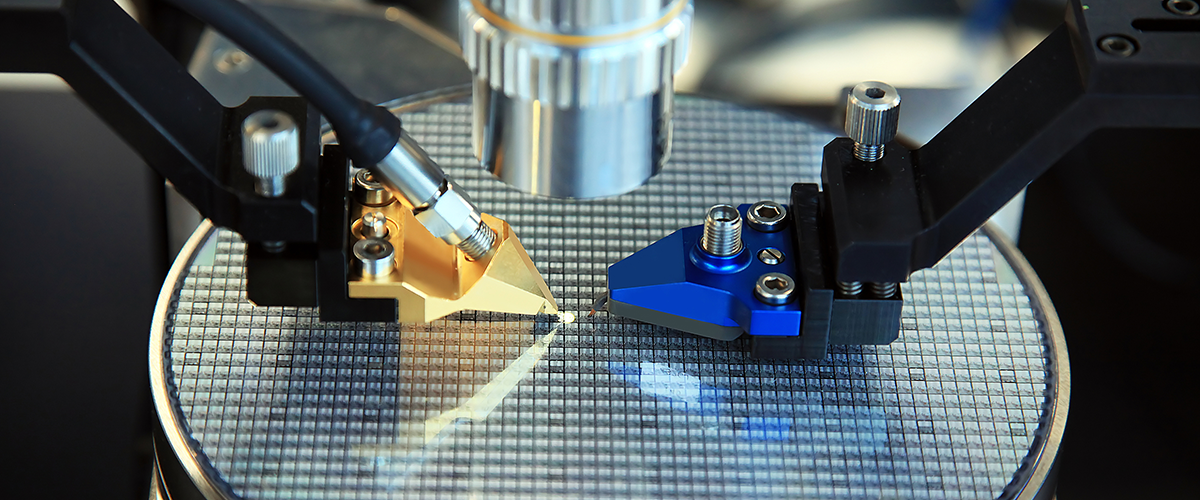

Mekhoa ea setso ea ho lekanya ea mechine hangata e haella ho fihlela litlhoko tse joalo tse nepahetseng haholo. Ho feta moo, e ipeha kotsing ea ho senya kapa ho silafatsa bokaholimo ba wafer bo fokolang, ha lebelo la eona la karabelo le liehang le etsa hore e se lekane bakeng sa litlhoko tsa metrology ea sejoale-joale.

LanbaokutloLi-sensor tsa ho Furalla Laser tsa PDE SeriesTharollo e Molemohali bakeng sa Likopo tsa Wafer

◆Tekanyo ea Laser e sa amaneng le motho

E sebelisa tlhahiso ea mahlaseli a laser holim'a libaka tse reretsoeng, e sekaseka matšoao a bonahalitsoeng/a hasaneng ho fumana lintlha tsa ho falla - e felisa ho kopana 'meleng le li-wafer ho thibela tšenyo ea mechini le likotsi tsa tšilafalo.

◆Ho nepahala ha boemo ba micron

Theknoloji e tsoetseng pele ea laser le li-algorithms tsa ts'ebetso ea matšoao li fana ka ho nepahala le qeto ea tekanyo ea micrometer, li fihlela litlhoko tse phahameng tsa ho nepahala ha lits'ebetso tsa tlhahiso ea wafer.

◆Karabelo e Potlakileng Haholo (<10ms)

E nolofalletsa ho beha leihlo ka nako ea sebele ea liphetoho tse matla tsa tlhahiso, e lumellang ho lemoha le ho lokisa ho kheloha hang-hang ho ntlafatsa katleho ea tlhahiso.

◆Ho lumellana ho ikhethang ha thepa

E khona ho lekanya thepa e fapaneng le mefuta ea bokaholimo ka ho ikamahanya le maemo a tikoloho ka matla, e loketse mekhahlelo e mengata ea ts'ebetso ea semiconductor.

◆Moralo o Monyenyane oa Liindasteri

Ntlha e kopaneng e thusa ho kopanya ka mokhoa o se nang sekoli lisebelisoa le litsamaiso tsa taolo tse iketsang, e nolofalletsang tlhokomelo e bohlale ea ts'ebetso le phetoho ea selika-likoe se koetsoeng.

Maemo a Kopo aLi-sensor tsa ho Furalla Laser tsa PDE SeriesTs'ebetsong ea Wafer

Sensor ea LanbaoLi-sensor tsa ho Furalla Laser tsa PDE SeriesLikopo tsa Bohlokoa Tlhahisong ea Wafer

Ka ts'ebetso e ikhethang, li-sensor tsa ho falla ha laser tsa Lansensor PDE li bapala karolo ea bohlokoa lits'ebetsong tse ngata tsa tlhahiso ea wafer:

◆Ho Lokisa le ho Beha Wafer

Bakeng sa lits'ebetso tsa photolithography le ho kopanya tse hlokang ho nepahala ha boemo ba micron, li-sensor tsa rona li lekanya boemo ba wafer le likhutlo tse sekameng ka nepo ho netefatsa ho lumellana ho phethahetseng ha maske le wafer le ho beha letsoho la ho kopanya - ho ntlafatsa ho nepahala ha phetisetso ea paterone.

◆Metrology ea Botenya ba Wafer

Ho nolofalletsa tekanyo ea botenya bo sa amaneng le ho beha leihlo ka nako ea sebele nakong ea lits'ebetso tsa ho beha, ho netefatsa taolo e ntle ea boleng ba filimi e tšesaane.

◆Tlhahlobo ea Boreleli ba Wafer

Ho lemoha warpage ea wafer le phetoho ea bokaholimo ka qeto ea sub-micron ho thibela li-wafer tse nang le sekoli hore li se ke tsa tsoela pele ho ea tlaase.

◆Tlhokomelo ea Botenya ba Filimi e Nyenyane

Ho fana ka ho latela botenya ba ho boloka thepa ka nako ea sebele nakong ea lits'ebetso tsa CVD/PVD ho boloka litlhaloso tse tiileng tsa ts'ebetso ea motlakase.

◆Ho Sibolloa ha Sekoli se Phethahetseng holim'a Sefahleho

Ho hlwaya diphoso tse ka hodima bokahodimo ba micron (mengoapo, dikarolwana) ka ho etsa 'mapa wa ho falla o nang le qeto e phahameng, ho ntlafatsa haholo sekgahla sa ho lemoha diphoso.

◆Tlhokomelo ea Boemo ba Lisebelisoa

Ho latela ho falla ha likarolo tsa bohlokoa (matsoho a roboto, metsamao ea sethala) le ho thothomela ha mochini bakeng sa tlhokomelo e boletsoeng esale pele le ntlafatso ea botsitso.

Letoto la PDE la sensor la Lanbao ha le koale feela likheo tsa bohlokoa tsa theknoloji 'marakeng oa li-sensor tsa indasteri oa China empa le theha litekanyetso tse ncha tsa lefats'e ka ts'ebetso ea lona e ikhethang. Ebang ke ho eketsa sekhahla sa chai, ho fokotsa litšenyehelo tsa tlhahiso, kapa ho potlakisa nts'etsopele ea ts'ebetso ea moloko o latelang, letoto la PDE le eme e le sebetsa sa hau sa ho qetela sa ho hlola liphephetso tsa tlhahiso ea semiconductor e nepahetseng!

Nako ea poso: Mots'eanong-08-2025