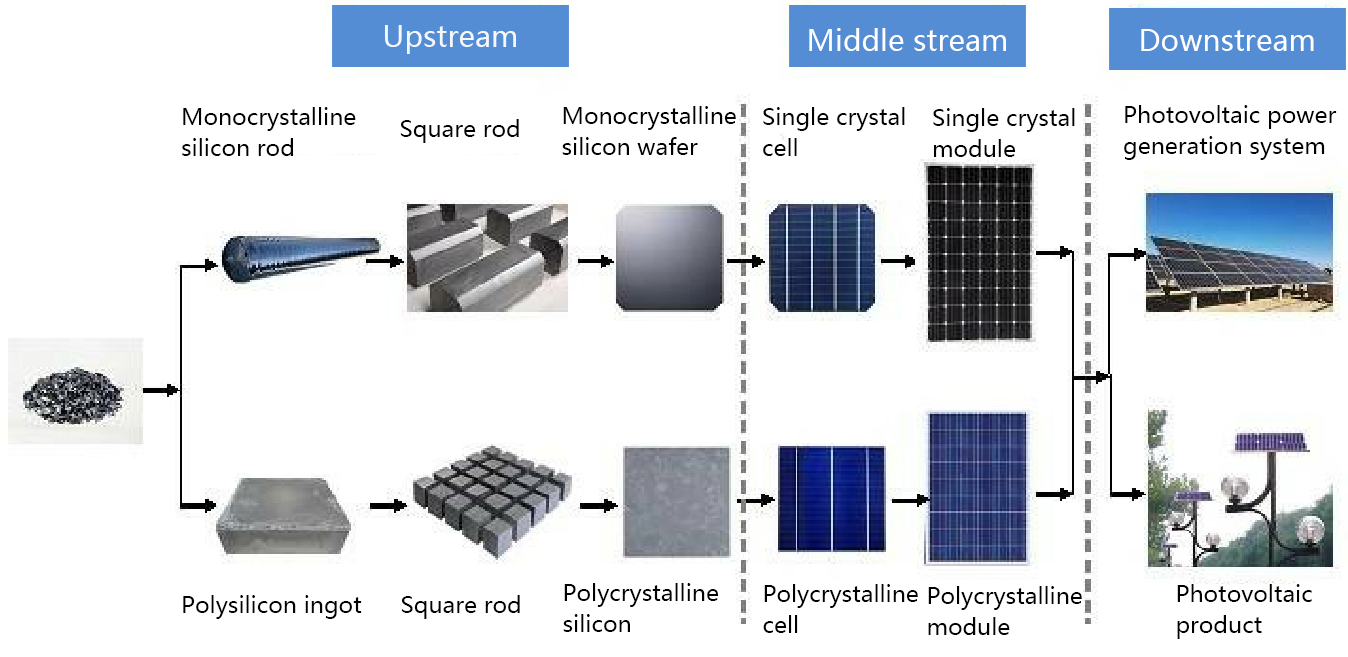

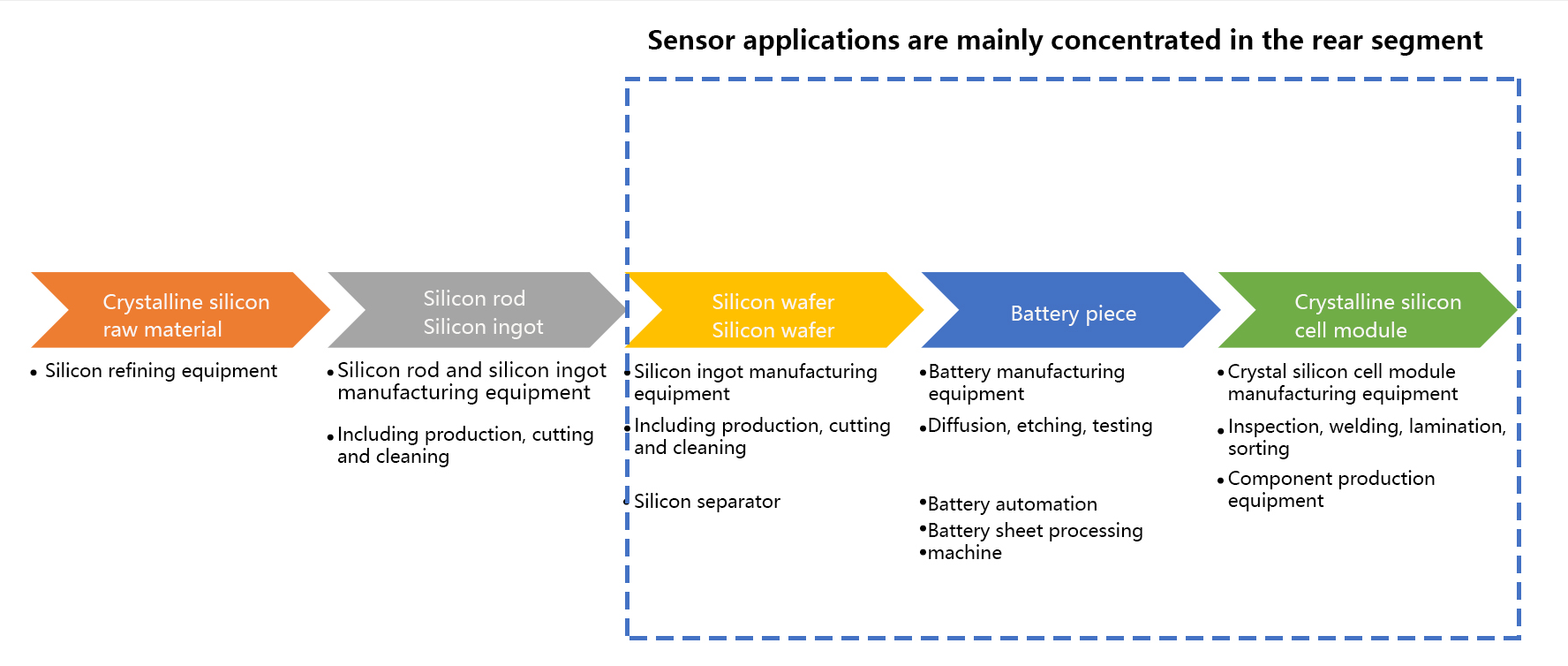

Iyada oo ah tamar nadiif ah oo la cusboonaysiin karo, photovoltaic-gu wuxuu door muhiim ah ka ciyaaraa qaab-dhismeedka tamarta mustaqbalka. Marka laga eego dhinaca silsiladda warshadaha, wax soo saarka qalabka photovoltaic-ga waxaa lagu soo koobi karaa sida wax soo saarka silicon wafer-ka sare, wax soo saarka wafer-ka batteriga dhexe iyo wax soo saarka module-ka hoose. Qalab kala duwan oo wax soo saar ah ayaa ku lug leh xiriir kasta oo wax soo saar ah. Iyadoo la horumarinayo tignoolajiyada wax soo saarka ee joogtada ah, shuruudaha saxda ah ee hababka wax soo saarka iyo qalabka wax soo saarka ee la xiriira ayaa sidoo kale si joogto ah u soo hagaagaya. Marxalad kasta oo wax soo saarka habka, codsiga qalabka otomaatiga ah ee habka wax soo saarka photovoltaic-ga wuxuu door muhiim ah ka ciyaaraa isku xirka wixii hore iyo mustaqbalka, hagaajinta hufnaanta iyo yaraynta kharashyada.

Baytariyadu waxay door muhiim ah ka ciyaaraan geeddi-socodka wax-soo-saarka oo dhan ee warshadaha sawir-qaadista. Qolof kasta oo baytari ah oo laba jibbaaran wuxuu ka kooban yahay qolof iyo saxan dabool ah kaas oo ah qaybta ugu muhiimsan si loo hubiyo badbaadada baytariga lithium. Waxaa lagu shaabadeyn doonaa qolofka unugga batteriga, wax soo saarka tamarta gudaha, waxaana la hubin doonaa qaybaha muhiimka ah ee badbaadada unugga batteriga, kaas oo leh shuruudo adag oo ku saabsan shaabadda qaybaha, cadaadiska waalka gargaarka, waxqabadka korontada, cabbirka iyo muuqaalka.

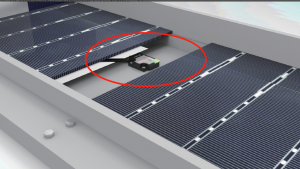

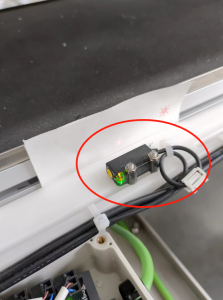

Sida nidaamka dareenka ee qalabka otomaatiga ah,dareemahawaxay leedahay astaamo dareen sax ah, rakibid dabacsan iyo jawaab degdeg ah. Sida loo doorto dareemayaal ku habboon iyadoo loo eegayo xaalad shaqo oo gaar ah, si loo gaaro ujeeddada dhimista kharashka, kordhinta hufnaanta iyo hawlgalka xasilloon. Waxaa jira xaalado shaqo oo kala duwan oo ku jira habka wax soo saarka, iftiin deegaan oo kala duwan, laxanka wax soo saarka ee kala duwan iyo wafers silicon midab kala duwan leh, sida silicon ka dib marka la jaro dheemanka, silicon cawlan iyo wafer buluug ah ka dib dahaarka velvet, iwm. labaduba waxay leeyihiin shuruudo adag. Dareemaha Lanbao wuxuu bixin karaa xal bisil oo loogu talagalay isu-imaatinka otomaatiga ah iyo soo saarista kormeerka saxanka daboolka batteriga.

Taabashada Dambe ee Soo-saarayaasha ee Passivated, oo ah teknoolojiyadda batteriga ee passivation iyo tignoolajiyada baytariyada ee back passivation. Badanaa, iyadoo lagu saleynayo baytariyada caadiga ah, filimka aluminium oxide iyo silicon nitride ayaa lagu dahaadhay dhabarka, ka dibna filimka waxaa lagu furaa laysarka. Waqtigan xaadirka ah, waxtarka beddelka ee unugyada habka PERC wuxuu ku dhowaa xadka aragtiyeed ee 24%.

Dareemayaasha Lanbao waxay qani ku yihiin noocyada waxaana si weyn loogu isticmaalaa qaybaha kala duwan ee habka wax soo saarka baytariyada PERC. Dareemayaasha Lanbao ma aha oo kaliya inay gaaraan meel deggan oo sax ah iyo ogaanshaha booska, laakiin sidoo kale waxay dabooli karaan baahiyaha wax soo saarka xawaaraha sare, iyagoo kor u qaadaya hufnaanta iyo dhimista kharashka wax soo saarka sawir-qaadista.

Codsiyada dareemayaasha ee mashiinka gacanta

| Booska shaqada | Codsiga | Badeecada |

| Foornada daaweynta, ILD | Ogaanshaha goobta gaariga birta ah | Dareemaha Inductive-taxane u adkaysta heerkulka sare |

| Qalabka wax soo saarka baytariga | Helitaanka meesha laga helo wafer silicon ah, side wafer ah, doon tareen iyo doon graphite ah | Sensoe-ka sawir-qaadistaTaxanaha milicsiga ee PSE-fog |

| (Daabacaadda shaashadda, xariiqda raadraaca, iwm.) | ||

| Saldhigga Caalamiga ah - Module-ka Dhaqdhaqaaqa | Goobta asalka ah | Dareemaha Sawirka Korontada-taxanaha booska PU05M/PU05S ee sloat |

Codsiyada dareemayaasha ee mashiinka gacanta

| Booska shaqada | Codsiga | Badeecada |

| Qalabka nadiifinta | Ogaanshaha heerka dhuumaha | Dareemaha Awoodda-Taxanaha CR18 |

| Khadka tareenka | Ogaanshaha joogitaanka iyo ogaanshaha meesha ee wafer silicon ah; Ogaanshaha joogitaanka waferka ... | Dareemaha awoodda-Taxanaha CE05, taxanaha CE34, Dareemaha sawir-qaadista-Taxanaha PSV(doorashada isku-dhafka ah), taxanaha PSV (xakamaynta asalka ah) |

| Gudbinta raadadka | Ogaanshaha markabka wafer-ka qaada iyo goobta doonida quartz | Dareemaha Cpacitive-Taxanaha CR18, dareemaha sawir-koronto-Taxanaha PST(xakamaynta asalka / milicsiga alwaaxa), taxanaha PSE (iyada oo loo marayo milicsiga alwaaxa) |

| Koobka nuugista, hoos u riix, kor u qaadista farsamada | Ogaanshaha joogitaanka jajabyada silikoon | Dareemaha sawir-qaadista-Taxanaha PSV(milicsiga isku-dhafka ah), taxanaha PSV (xakamaynta asalka ah), Dareemaha Cpacitive-Taxanaha CR18 |

| Qalabka wax soo saarka baytariga | Ogaanshaha joogitaanka side-qaadaha wafer-ka iyo jajabyada silikoon / Ogaanshaha booska quartz-ka | Dareemaha sawir-qaadista-Taxanaha PSE(xakamaynta asalka) |

Waqtiga boostada: Luulyo-19-2023