Wax soo saarka Semiconductor-ka wuxuu u taagan yahay mid ka mid ah meelaha ugu saxsan uguna adag ee teknoolojiyadda warshadaha casriga ah ee maanta. Maadaama hababka chip-ku ay u socdaan 3nm iyo xitaa qanjidhada yaryar, saxnaanta cabbiraadda dhumucda wafer-ka, fidsanaanta dusha sare, iyo cabbirrada qaab-dhismeedka yar yar si toos ah ayay u go'aamiyaan wax soo saarka iyo waxqabadka chip-ka. Xaaladdan oo kale, dareemayaasha barokaca laysarka, oo leh hawlgalkooda aan xiriirka lahayn, saxnaanta sare, waqtiyada jawaab celinta degdegga ah, iyo xasilloonida la xoojiyay, waxay noqdeen "indho cabbir" oo aan lagama maarmaan ahayn inta lagu jiro habka wax soo saarka semiconductor-ka.

Maadaama ay tahay aasaaska ugu muhiimsan ee sameynta qalabka semiconductor-ka, wafer-yadu waxay u baahan yihiin saxnaan iyo isku hallayn xad dhaaf ah inta lagu jiro wax soo saarka. Marxaladaha badan ee muhiimka ah ee soo saarista wafer-ka, cabbirka saxda ah ee barokaca ayaa ah mid aad muhiim u ah - waxay si toos ah u saamaysaa waxqabadka iyo wax soo saarka chip-ka ugu dambeeya. Iyada oo ah hoggaamiye hal-abuur leh oo ka tirsan qaybta dareemayaasha warshadaha ee Shiinaha, dareemayaasha barokaca laysarka ee taxanaha Lansensor ee PDE, oo leh xallinta heerka micron-ka, algorithms-ka caqliga badan, iyo isku halaynta heerka warshadaha, ayaa soo ifbaxay iyagoo ah xalka la doorbidayo ee hababka wax soo saarka wafer-ka.

Caqabadaha Saxda ah ee Soo saarista Wafer-ka iyo Faa'iidooyinka Dareemayaasha Barakaca Laser-ka

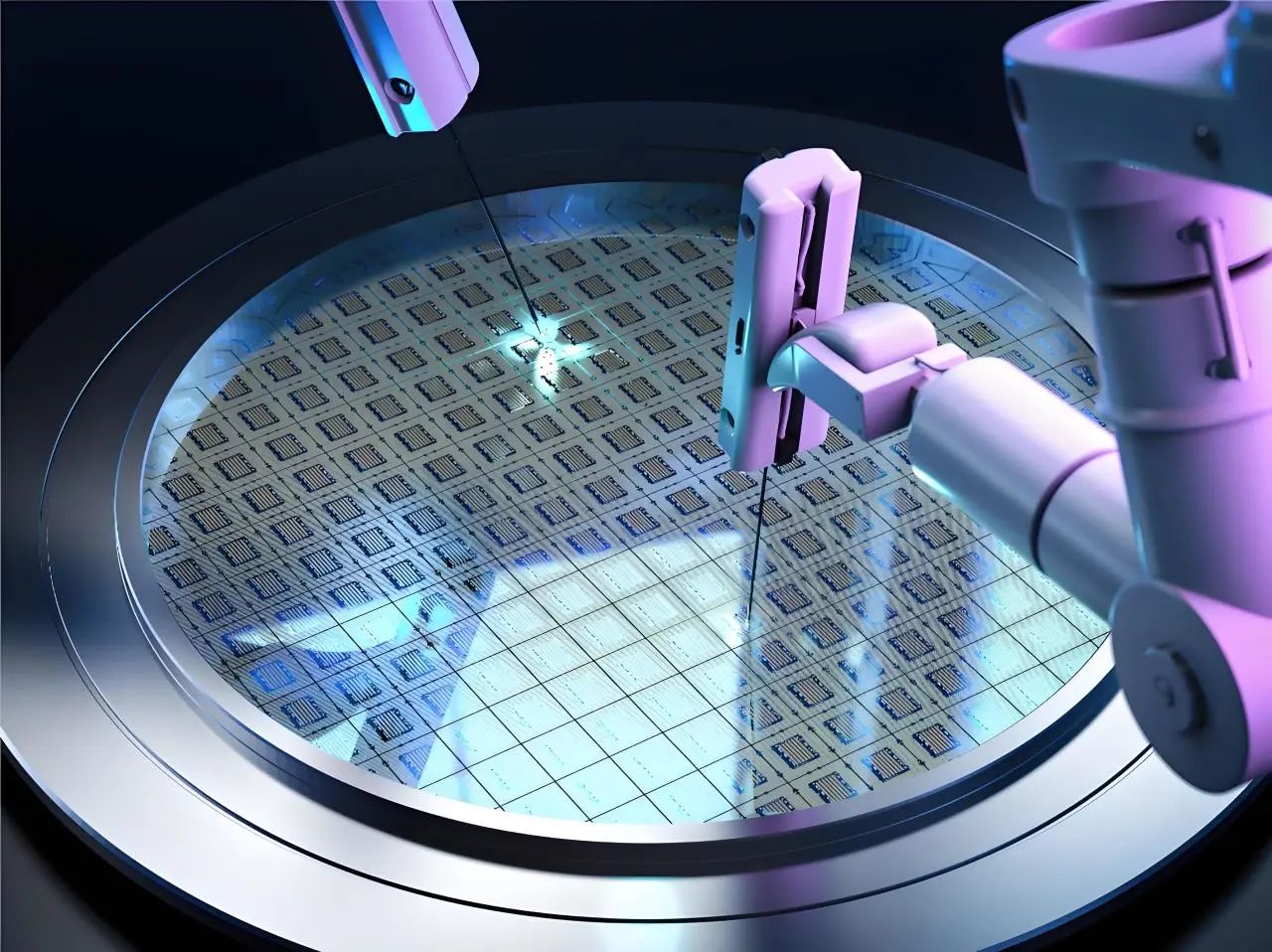

Soo saarista Wafer waxay ku lug leedahay taxane ah habab isku dhafan sida sawir-qaadista, xoqidda, dhigista filim khafiif ah, iyo isku xidhka - mid walbana wuxuu u baahan yahay saxnaan adag oo heer micrometer ah ama xitaa nanometer ah. Tusaale ahaan:

-

Sawirka sawirka, isku-xidhka saxda ah ee u dhexeeya maaskarada sawirka iyo wafer-ka ayaa muhiim u ah hubinta in qaabka saxda ah loo wareejiyo dusha sare ee wafer-ka.

-

Inta lagu jiro kaydinta filimka khafiifka ah, xakamaynta saxda ah ee dhumucda filimka ayaa lagama maarmaan u ah hubinta waxqabadka korantada ee aaladaha.

Xitaa leexashada ugu yar waxay keeni kartaa cillado badeecad ama xitaa waxay ka dhigi kartaa dufcad dhan oo wafer ah mid aan la isticmaali karin.

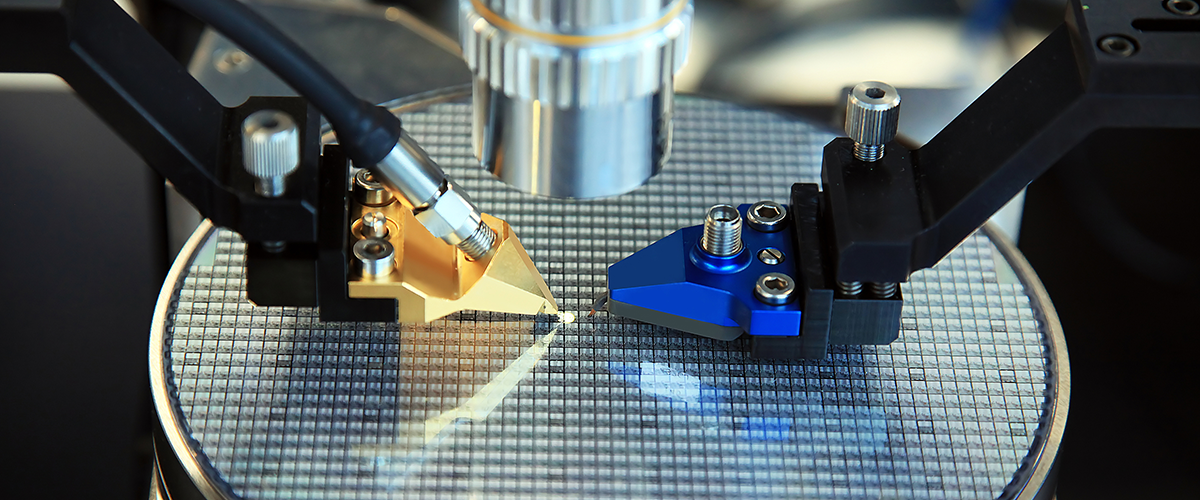

Hababka cabbiraadda farsamada dhaqameed badanaa way ku yar yihiin buuxinta baahiyaha saxda ah ee noocaas ah. Intaa waxaa dheer, waxay halis ugu jiraan inay waxyeelleeyaan ama wasakheeyaan dusha sare ee wafer-ka jilicsan, halka xawaaraha jawaab celintooda gaabiska ah ay ka dhigayaan kuwo aan ku filnayn shuruudaha mitirka casriga ah.

LanbaodareemahaDareemayaasha Barakaca Laser-ka Taxanaha PDEXalka ugu Fiican ee Codsiyada Wafer-ka

◆Cabbirka Laser-ka ee aan taabashada lahayn

Wuxuu adeegsadaa saadaasha iftiinka laysarka dusha sare ee bartilmaameedka, isagoo falanqeynaya calaamadaha muuqda/kala firirsan si uu u helo xogta barokaca - isagoo meesha ka saaraya taabashada jireed ee wafers-ka si looga hortago waxyeelada farsamada iyo khataraha wasakheynta.

◆Saxnaanta Heerka Micron

Tiknoolajiyadda laysarka ee horumarsan iyo algorithms-ka habaynta calaamadaha waxay bixiyaan saxnaanta iyo xallinta cabbirka cabbirka mitirka, iyagoo daboolaya shuruudaha saxda ah ee hababka soo saarista wafer-ka.

◆Jawaab aad u dhakhso badan (<10ms)

Waxay awood u siineysaa la socodka waqtiga-dhabta ah ee kala duwanaanshaha wax soo saarka firfircoon, taasoo u oggolaaneysa ogaanshaha leexashada degdega ah iyo sixitaanka si kor loogu qaado hufnaanta wax soo saarka.

◆Iswaafajinta Walxaha Gaarka ah

Awood u leh cabbiraadda agabyada kala duwan iyo noocyada dusha sare iyadoo la qabsan karo deegaanka oo xooggan, oo ku habboon marxalado badan oo geeddi-socodka semiconductor-ka ah.

◆Naqshadeynta Warshadaha ee Is-waafajinta

Qaabka is haysta wuxuu fududeeyaa is-dhexgal aan kala go 'lahayn oo ku jira qalabka otomaatiga ah iyo nidaamyada xakamaynta, taasoo suurtogalinaysa la socodka habka caqliga leh iyo hagaajinta wareegga xiran.

Xaaladaha Codsiga eeDareemayaasha Barakaca Laser-ka Taxanaha PDEku jira Wafer Processing

Dareemaha LanbaoDareemayaasha Barakaca Laser-ka Taxanaha PDEAdeegsiga Muhiimka ah ee Wax-soo-saarka Wafer-ka

Iyada oo leh waxqabad heer sare ah, dareemayaasha barokaca laysarka ee Lansensor PDE waxay door muhiim ah ka ciyaaraan hababka soo saarista wafer-ka badan:

◆Isku-dubaridka iyo Meelaynta Wafer-ka

Hababka sawir-qaadista iyo isku-xidhka ee u baahan saxnaanta heerka micron-ka, dareemayaashayadu si sax ah ayay u cabbiraan booska wafer-ka iyo xaglaha janjeedhka si loo hubiyo isku-hagaajinta maaskarada-ilaa-wafer ee qumman iyo booska gacanta isku-xidhka - kor u qaadista saxnaanta wareejinta qaabka.

◆Jaantuska Dhumucda Wafer

Awoodsiinta cabbiraadda dhumucda aan taabashada lahayn iyadoo la kormeerayo waqtiga dhabta ah inta lagu jiro hababka dhigista, iyadoo la hubinayo xakamaynta tayada ugu wanaagsan ee filim khafiif ah.

◆Kormeerka Fidsan ee Wafer

Ogaanshaha isbeddelka wafer-ka iyo isbeddelka dusha sare iyadoo la adeegsanayo xallinta sub-micron si looga hortago in wafer-yada cilladaysan ay u socdaan dhinaca hoose.

◆Kormeerka Dhumucda Filimka Khafiifka ah

Bixinta dabagalka dhumucda dhigista waqtiga dhabta ah inta lagu jiro hababka CVD/PVD si loo ilaaliyo qeexitaannada waxqabadka korantada ee adag.

◆Ogaanshaha Cilladaha Dusha Sare

Aqoonsashada cilladaha dusha sare ee micron-scale (xoqitaan, walxo) iyada oo loo marayo khariidaynta barokaca xallinta sare leh, si weyn u hagaajinaysa heerarka ogaanshaha cilladaha.

◆La socodka Xaaladda Qalabka

La socodka barokaca qaybaha muhiimka ah (gacmaha robot-ka, dhaqdhaqaaqyada masraxa) iyo gariirka mashiinka si loo helo dayactir saadaalin ah iyo hagaajinta xasilloonida.

Taxanaha PDE ee dareemayaasha Lanbao ma aha oo kaliya inuu buuxiyo farqiga tignoolajiyada muhiimka ah ee suuqa dareemayaasha warshadaha ee heerka sare ah ee Shiinaha laakiin wuxuu dejiyaa halbeegyo caalami ah oo cusub oo leh waxqabadkiisa gaarka ah. Hadday tahay kor u qaadista heerarka wax soo saarka, yaraynta kharashyada wax soo saarka, ama dardargelinta horumarinta habka jiilka xiga, taxanaha PDE wuxuu u taagan yahay hubkaaga ugu dambeeya ee lagu guuleysto caqabadaha wax soo saarka semiconductor-ka saxda ah!

Waqtiga boostada: Maajo-08-2025