Mu gawo la opanga zinthu zopangidwa ndi semiconductor, kusakhazikika kwa ma chip stacking ndi vuto lalikulu pakupanga. Kuyika ma chips mosayembekezereka panthawi yopanga kungayambitse kuwonongeka kwa zida ndi kulephera kwa ntchito, komanso kungayambitse kutaya zinthu zambiri, zomwe zingayambitse kutayika kwakukulu kwachuma kwa mabizinesi.

Ndi kukonzanso kosalekeza kwa njira zopangira semiconductor, kufunikira kwakukulu kumayikidwa pakuwongolera khalidwe panthawi yopanga. Masensa osunthika a laser, monga ukadaulo wosakhudzana ndi kulondola kwambiri, amapereka njira yothandiza yodziwira zolakwika za chip stacking ndi kuthekera kwawo kuzindikira mwachangu komanso molondola.

Mfundo Yozindikira ndi Malingaliro Oweruza Osazolowereka

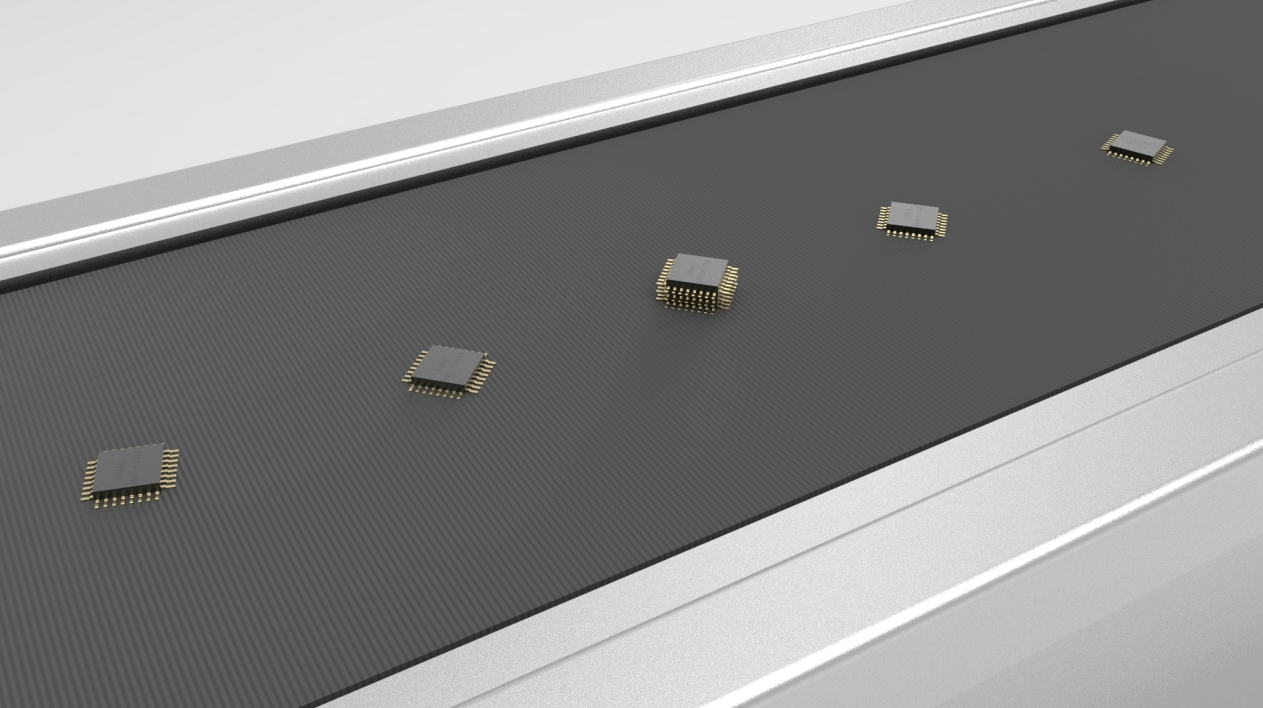

Mu njira yopangira ma semiconductor, ma chip nthawi zambiri amaikidwa pa zonyamulira kapena njira zonyamulira mu dongosolo limodzi losalala. Panthawiyi, kutalika kwa pamwamba pa chip ndi mtengo woyambira wokonzedweratu, nthawi zambiri kuchuluka kwa makulidwe a chip ndi kutalika kwa chonyamulira. Ma chip akamayikidwa mwangozi, kutalika kwawo pamwamba kumawonjezeka kwambiri. Kusinthaku kumapereka maziko ofunikira kwambiri pozindikira zolakwika pakuyika ma stacking.

Kuzindikira Kuchuluka kwa Mayendedwe a Njira Yoyendera

Ma track oyendera ndi njira zofunika kwambiri zoyendetsera ma chip panthawi yopanga. Komabe, ma chips amatha kusonkhana pa ma track chifukwa cha kulowetsedwa kwa ma electrostatic kapena kulephera kwa makina panthawi yoyendetsa, zomwe zimapangitsa kuti ma track atseke. Kutsekeka kotereku sikungosokoneza kayendedwe ka kupanga komanso kumawononga ma chips.

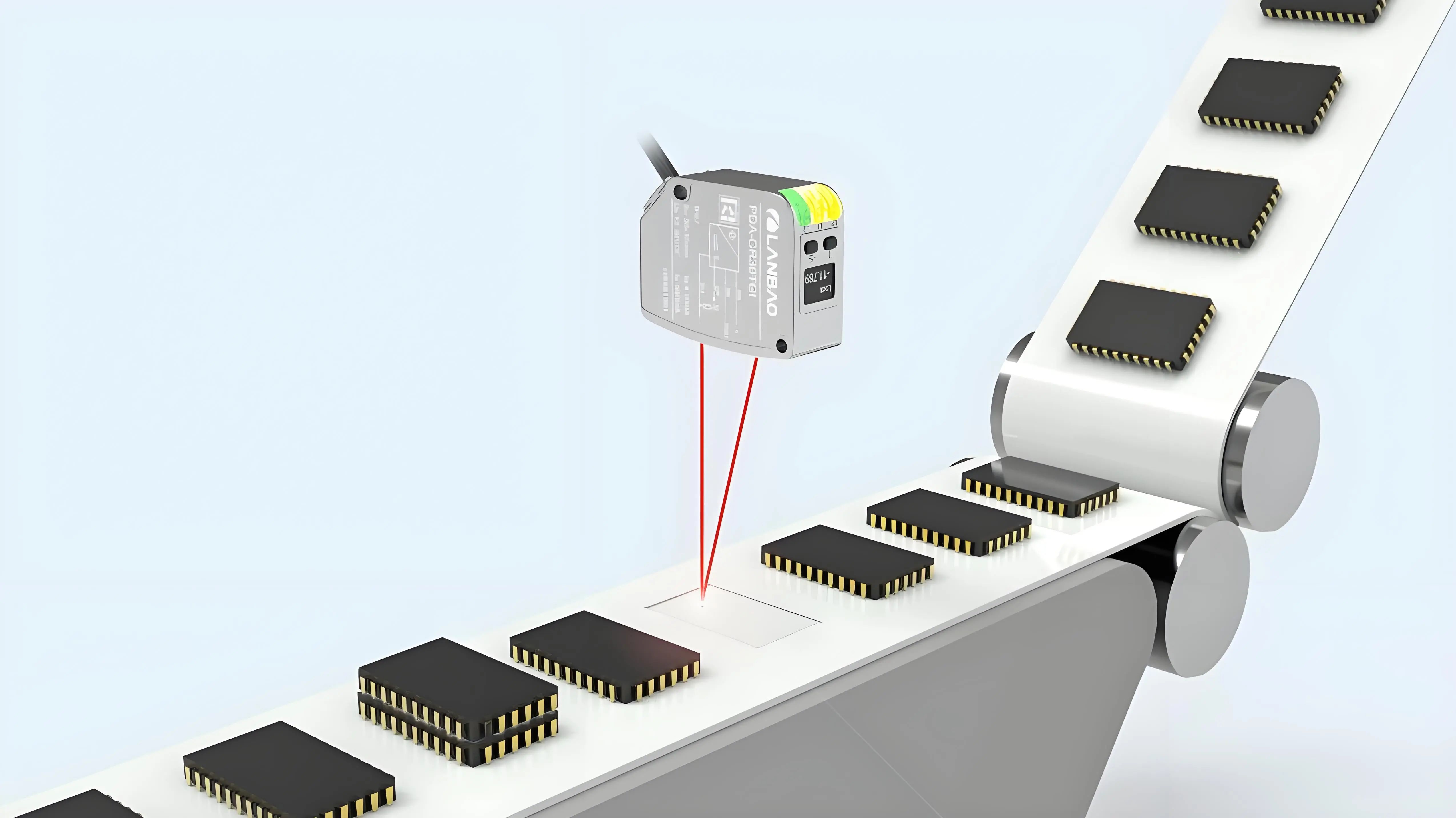

Kuti ayang'anire kayendedwe ka njanji zonyamulira popanda choletsa, masensa osunthika a laser amatha kuyikidwa pamwamba pa njanji kuti azitha kuwona kutalika kwa gawo la njanji. Ngati kutalika kwa malo omwe ali pamalopo kuli kosazolowereka (monga, kokwera kapena kotsika kuposa makulidwe a gawo limodzi la tchipisi), masensawo adzazindikira ngati kutsekeka kwa stacking ndikuyambitsa njira yochenjeza kuti idziwitse ogwiritsa ntchito kuti agwire ntchito nthawi yake, kuonetsetsa kuti ntchito ikuyenda bwino.

Njira Yodziwira

Masensa osunthika a laser a Lanbao amayesa molondola kutalika kwa malo omwe akufuna potulutsa kuwala kwa laser, kulandira chizindikiro chowunikira, ndikugwiritsa ntchito njira ya triangulation.

Sensa imayendetsedwa molunjika ndi malo ozindikira ma chip, imatulutsa laser mosalekeza ndikulandira chizindikiro chowonetsedwa. Pakutumiza ma chip, sensa imatha kupeza zambiri za kutalika kwa pamwamba nthawi yeniyeni.

Sensa imagwiritsa ntchito njira yamkati yowerengera kutalika kwa pamwamba pa chip kuchokera ku chizindikiro chomwe chawonetsedwa. Kuti ikwaniritse zofunikira zotumizira mwachangu kwambiri za mizere yopanga semiconductor, izi zimafuna kuti sensa ikhale ndi kulondola kwakukulu komanso pafupipafupi kwambiri.

Kusiyanasiyana kwa kutalika kovomerezeka kumakhazikitsidwa, nthawi zambiri ±30 µm kuchokera kutalika koyambira. Ngati mtengo woyesedwa ukupitirira malire awa, umawonedwa kuti ndi vuto la kukwera. Njira yodziwira malire iyi imatha kusiyanitsa bwino pakati pa ma chips wamba a single-layer ndi ma chips okhazikika.

Akazindikira vuto la kukwera kwa zinthu, sensa imayambitsa alamu yomveka komanso yowoneka bwino, ndipo nthawi yomweyo imayatsa mkono wa robotic kuti ichotse malo olakwikawo, kapena kuyimitsa mzere wopanga kuti zinthu zisawonjezeke. Njira yofulumira iyi yoyankhira imachepetsa kutayika komwe kumachitika chifukwa cha kukwera kwa zinthu mopitirira muyeso.

Kuzindikira molondola komanso nthawi yeniyeni zinthu zosakhazikika pa chip pogwiritsa ntchito masensa osuntha a laser kungathandize kwambiri kudalirika ndi kukolola kwa mizere yopanga semiconductor. Ndi kupita patsogolo kwaukadaulo kosalekeza, masensa osuntha a laser adzachita gawo lalikulu kwambiri pakupanga semiconductor, kupereka chithandizo champhamvu pakukula kokhazikika kwa makampaniwa.

Nthawi yotumizira: Marichi-25-2025