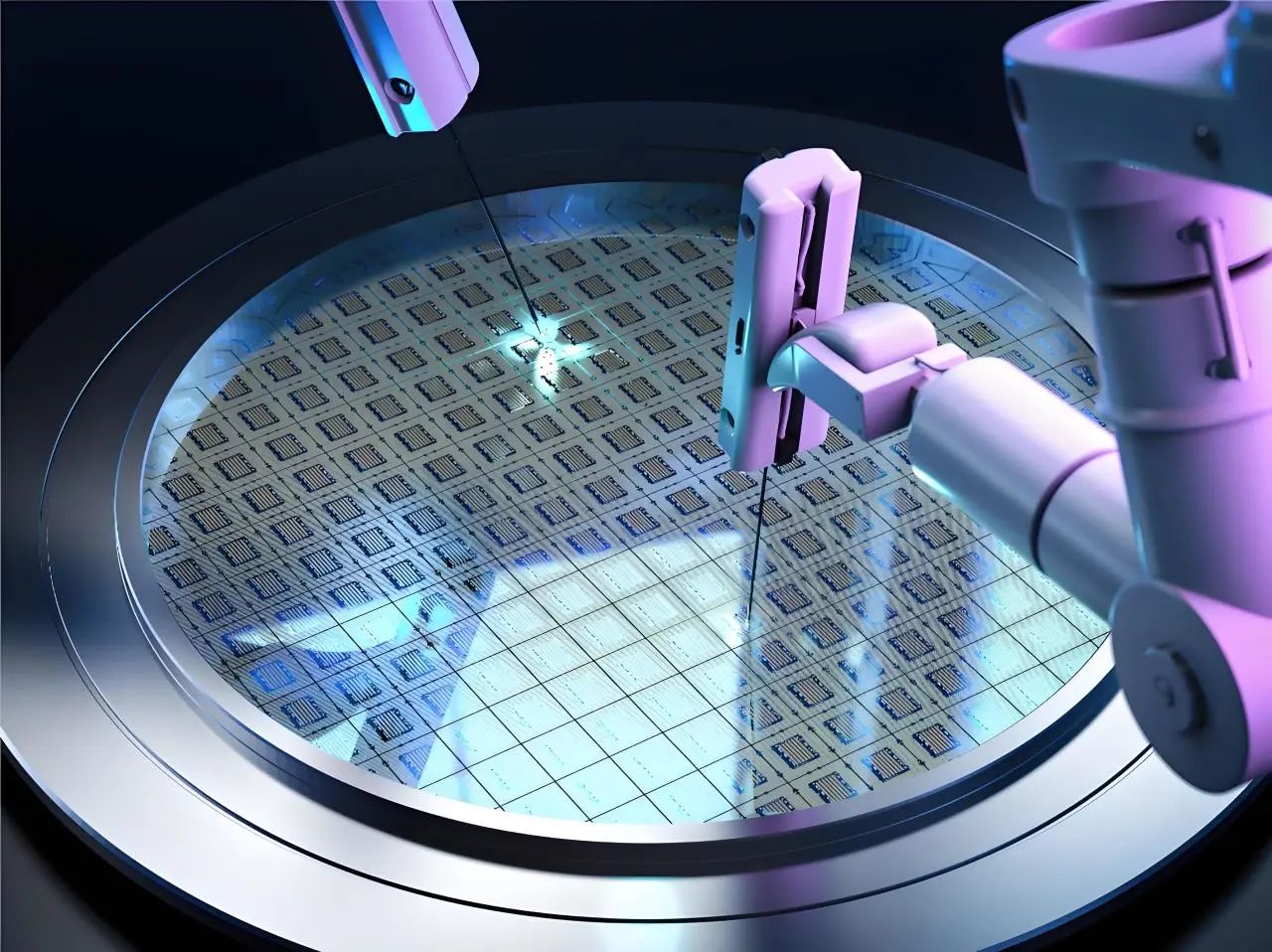

Kera na'urorin Semiconductor yana ɗaya daga cikin fannoni mafi buƙatar daidaito da sarkakiya a fannin fasaha a masana'antar fasahar zamani ta yau. Yayin da hanyoyin guntu ke ci gaba zuwa 3nm har ma da ƙananan ƙwayoyin cuta, daidaiton ma'auni don kauri wafer, madaidaicin saman, da girman ƙananan ƙwayoyin cuta kai tsaye yana ƙayyade yawan amfanin guntu da aiki. A cikin wannan mahallin, na'urori masu auna firikwensin motsa jiki na laser, tare da aikinsu na rashin hulɗa, daidaito mafi kyau, lokutan amsawa cikin sauri, da ingantaccen kwanciyar hankali, sun zama "ido na aunawa" masu mahimmanci a duk lokacin ƙera semiconductor.

A matsayin babban tushen ƙera na'urorin semiconductor, wafers suna buƙatar daidaito da aminci sosai yayin samarwa. Daga cikin matakai masu mahimmanci na ƙera wafer, daidaitaccen ma'aunin ƙaura yana da matuƙar muhimmanci - yana shafar aikin guntu na ƙarshe da yawan amfanin sa. A matsayin jagora a fannin gano sabbin abubuwa a fannin na'urorin lantarki na masana'antu na China, na'urori masu auna firikwensin laser na Lansensor PDE, waɗanda ke da ƙudurin matakin micron, algorithms masu wayo, da amincin matakin masana'antu, sun fito a matsayin mafita mafi dacewa ga hanyoyin ƙera wafer.

Kalubalen Daidaito a Masana'antar Wafer da Fa'idodin Na'urori Masu Saurin Fitarwa da Laser

Kera wafer ya ƙunshi jerin matakai masu rikitarwa kamar photolithography, etching, thinner-film deposition, da kuma haɗin kai—kowannensu yana buƙatar daidaito mai ƙarfi a matakin micrometer ko ma nanometer. Misali:

-

A fannin photolithography, daidaito tsakanin abin rufe fuska da wafer yana da matuƙar muhimmanci don tabbatar da daidaiton canja wurin tsari zuwa saman wafer.

-

A lokacin da aka ajiye fim ɗin siriri, cikakken iko kan kauri na fim ɗin yana da mahimmanci don tabbatar da aikin lantarki na na'urori.

Ko da ƙaramin karkacewa na iya haifar da lahani ga samfurin ko ma ya sa cikakken tarin wafers ɗin ba za a iya amfani da su ba.

Hanyoyin aunawa na gargajiya galibi ba sa aiki yadda ya kamata wajen biyan buƙatun da suka dace. Bugu da ƙari, suna fuskantar haɗarin lalata ko gurɓata saman wafer mai rauni, yayin da saurin amsawarsu mai jinkirin sa ya sa ba su da isasshen buƙatun ilimin kimiyyar lissafi na zamani.

LanbaofirikwensinNa'urori Masu auna Firikwensin Lasisin PDE Series: Mafi kyawun Maganin Aikace-aikacen Wafer

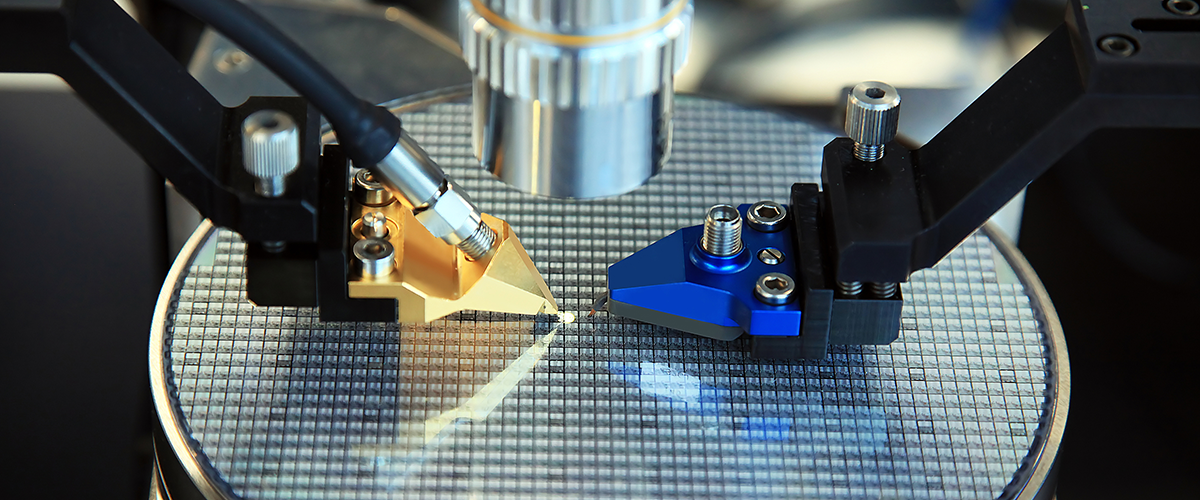

◆Ma'aunin Laser mara hulɗa

Yana amfani da haskokin laser a saman da aka nufa, yana nazarin siginar da aka nuna/watsa don samun bayanan ƙaura - yana kawar da hulɗa ta jiki da wafers don hana lalacewar injiniya da haɗarin gurɓatawa.

◆Daidaiton matakin Micron

Fasahar laser mai ci gaba da kuma tsarin sarrafa sigina suna samar da daidaito da ƙuduri na ma'aunin ma'aunin micrometer, wanda ke biyan buƙatun tsarin ƙera wafer mai tsauri.

◆Amsa mai sauri sosai (<10ms)

Yana ba da damar sa ido kan bambance-bambancen samarwa masu ƙarfi a ainihin lokaci, yana ba da damar gano karkacewa nan take da gyara don haɓaka ingancin masana'antu.

◆Daidaiton Kayan Aiki Na Musamman

Mai ikon auna abubuwa daban-daban da nau'ikan saman tare da ƙarfin daidaitawar muhalli, wanda ya dace da matakai da yawa na aiwatar da semiconductor.

◆Tsarin Masana'antu Mai Ƙaramin Sauƙi

Tsarin tsari mai sauƙi yana sauƙaƙa haɗakar kayan aiki ta atomatik da tsarin sarrafawa, yana ba da damar sa ido kan tsari mai wayo da daidaitawar madauki.

Yanayin Aikace-aikace naNa'urori Masu auna Firikwensin Lasisin PDE Seriesa cikin Sarrafa Wafer

Na'urar firikwensin LanbaoNa'urori Masu auna Firikwensin Lasisin PDE Series: Muhimman Amfani a Masana'antar Wafer

Tare da aiki mai kyau, na'urori masu auna firikwensin laser na Lansensor PDE suna taka muhimmiyar rawa a cikin hanyoyin ƙirƙirar wafer da yawa:

◆Daidaito da Matsayi na Wafer

Don tsarin daukar hoto da haɗin kai da ke buƙatar daidaiton matakin micron, na'urorin aunawa namu suna auna matsayin wafer da kusurwoyin karkatarwa daidai don tabbatar da daidaiton abin rufe fuska da wurin ɗaure hannu - yana haɓaka daidaiton canja wurin tsari.

◆Tsarin Kauri na Wafer

Yana ba da damar auna kauri mara hulɗa tare da sa ido a ainihin lokacin yayin aiwatar da adana bayanai, yana tabbatar da ingantaccen sarrafa ingancin fim ɗin siriri.

◆Dubawar Faɗin Wafer

Gano warpage na wafer da nakasar saman tare da ƙudurin sub-micron don hana wafers masu lahani su ci gaba zuwa ƙasa.

◆Kula da Kauri na Fim ɗin Sirara

Samar da bin diddigin kauri na ajiya a ainihin lokaci yayin ayyukan CVD/PVD don kiyaye takamaiman ƙayyadaddun aikin lantarki.

◆Gano Lalacewar Sama

Gano matsalolin saman micron-scale (karce, barbashi) ta hanyar taswirar ƙaura mai ƙuduri mai girma, yana inganta yawan gano lahani sosai.

◆Kula da Yanayin Kayan Aiki

Bin diddigin matsugunan da ke cikin sassan (hannun robot, motsin mataki) da girgizar injina don gyarawa da inganta kwanciyar hankali.

Jerin PDE na na'urorin firikwensin Lanbao ba wai kawai yana cike gibin fasaha a kasuwar na'urorin firikwensin masana'antu ta China ba, har ma yana kafa sabbin ma'auni na duniya tare da kyakkyawan aikinta. Ko dai ƙara yawan amfanin ƙasa, rage farashin samarwa, ko haɓaka haɓaka tsarin zamani na gaba, jerin PDE suna tsaye a matsayin makamin ku na ƙarshe don shawo kan ƙalubalen kera semiconductor daidai gwargwado!

Lokacin Saƙo: Mayu-08-2025