A fannin masana'antar semiconductor, yawan tara guntu ba bisa ƙa'ida ba matsala ce ta samarwa. Tara guntu ba tare da tsammani ba yayin aikin ƙera na iya haifar da lalacewar kayan aiki da gazawar tsari, kuma yana iya haifar da rushewar kayayyaki da yawa, wanda ke haifar da asarar tattalin arziki mai yawa ga kamfanoni.

Tare da ci gaba da inganta hanyoyin kera semiconductor, ana buƙatar ƙarin buƙatu kan kula da inganci yayin samarwa. Na'urori masu auna firikwensin Laser, a matsayin fasahar aunawa mai inganci, ba tare da taɓawa ba, suna samar da mafita mai inganci don gano matsalolin tara guntu tare da iyawar gano su cikin sauri da daidaito.

Ka'idar Ganowa da Tsarin Hukuncin Rashin Da'a

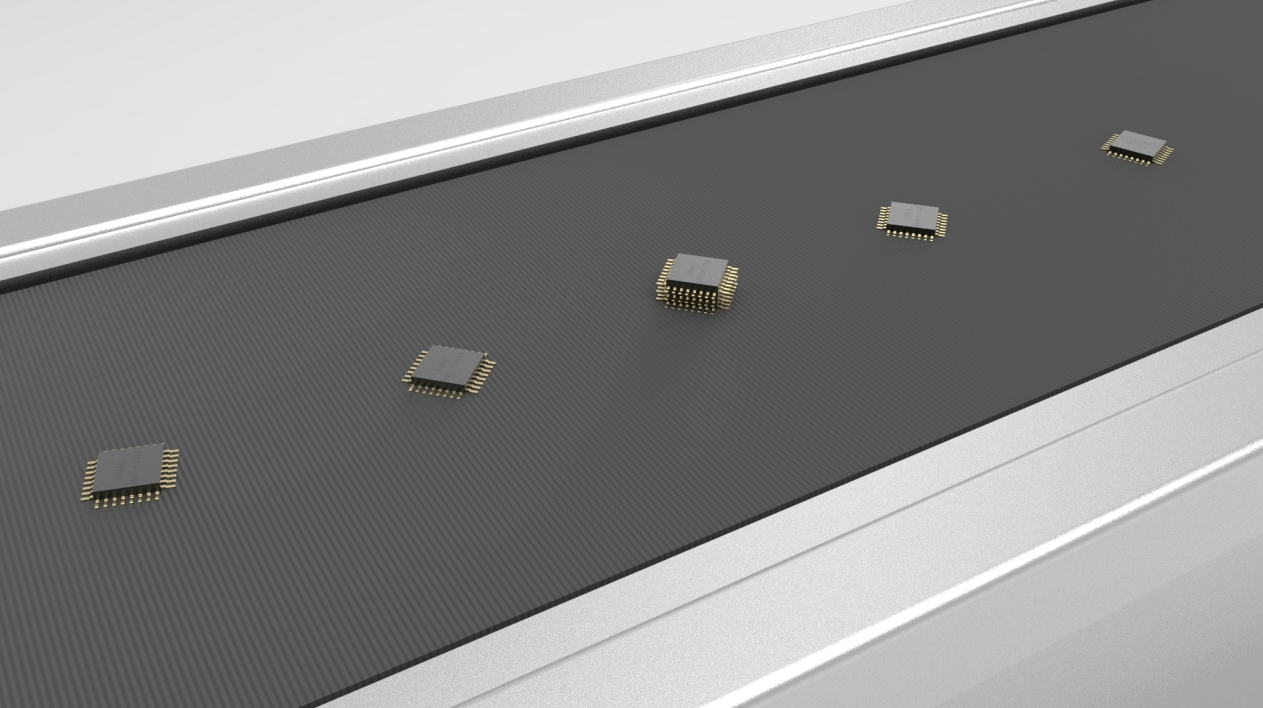

A tsarin kera na'urorin semiconductor, yawanci ana sanya guntu a kan masu ɗaukar kaya ko hanyoyin jigilar kaya a cikin tsari mai faɗi ɗaya. A wannan lokacin, tsayin saman guntu shine ƙimar tushe da aka riga aka saita, gabaɗaya jimlar kauri guntu da tsayin mai ɗaukar kaya. Lokacin da aka tara guntu ba da gangan ba, tsayin saman su zai ƙaru sosai. Wannan canjin yana ba da muhimmin tushe don gano matsalolin tarin.

Gano Tarin Layukan Sufuri

Layukan sufuri muhimman hanyoyin motsa guntu ne a lokacin aikin ƙera su. Duk da haka, guntu na iya taruwa a kan hanyoyin saboda shaƙar lantarki ko gazawar injina yayin sufuri, wanda ke haifar da toshewar hanyoyin. Irin waɗannan toshewar ba wai kawai za su iya katse kwararar samarwa ba har ma da lalata guntu.

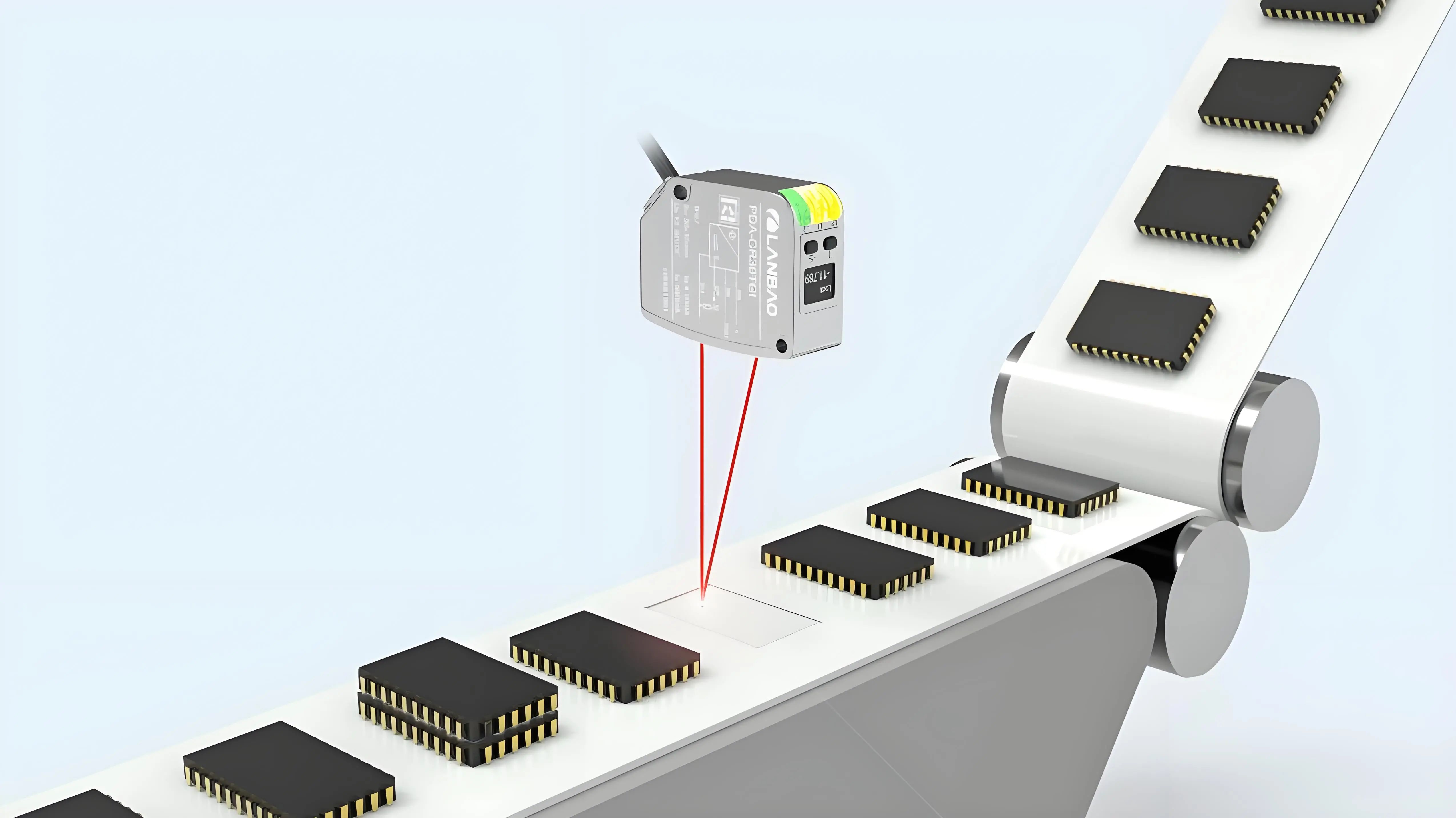

Domin lura da kwararar hanyoyin sufuri ba tare da wani cikas ba, ana iya tura na'urori masu auna motsi na laser a saman hanyoyin don duba tsayin hanyar da ke kan hanyar. Idan tsayin yankin da aka ware ba shi da kyau (misali, sama ko ƙasa da kauri na wani yanki ɗaya na guntu), na'urorin za su tantance shi a matsayin toshewar tarko kuma su haifar da tsarin faɗakarwa don sanar da masu aiki don sarrafa su akan lokaci, don tabbatar da ingantaccen kwararar samarwa.

Tsarin Ganowa

Na'urori masu auna motsi na laser na Lanbao suna auna tsayin saman da aka nufa daidai ta hanyar fitar da hasken laser, karɓar siginar da aka nuna, da kuma amfani da hanyar triangle.

Na'urar firikwensin tana daidaita a tsaye da yankin gano guntu, tana fitar da laser akai-akai kuma tana karɓar siginar da aka nuna. A lokacin jigilar guntu, na'urar firikwensin za ta iya samun bayanai game da tsayin saman a ainihin lokaci.

Na'urar firikwensin tana amfani da tsarin lissafi na ciki don ƙididdige ƙimar tsayin saman guntu daga siginar da aka nuna. Don biyan buƙatun canja wurin sauri na layukan samar da semiconductor, wannan yana buƙatar na'urar firikwensin ta sami daidaito mai girma da kuma mitar samfuri mai yawa.

An saita kewayon bambancin tsayi da aka yarda da shi, yawanci ±30 µm daga tsayin tushe. Idan ƙimar da aka auna ta wuce wannan kewayon iyaka, an ƙaddara ta a matsayin rashin daidaituwa na tara. Wannan dabarar tantance iyaka za ta iya bambanta yadda ya kamata tsakanin guntu-guntu na yau da kullun mai layi ɗaya da guntu-guntu masu tara.

Da zarar an gano wani rashin daidaituwa a cikin na'urar, na'urar firikwensin tana kunna ƙararrawa mai ji da gani, kuma a lokaci guda tana kunna hannun robot don cire wurin da ba shi da kyau, ko kuma ta dakatar da layin samarwa don hana ci gaba da tabarbarewar yanayin. Wannan hanyar amsawar gaggawa tana rage asarar da ke faruwa sakamakon tarin na'urori masu rikitarwa har zuwa mafi girman matakin.

Gano abubuwan da ba su dace ba na tara guntu ta amfani da na'urori masu auna firikwensin laser a ainihin lokaci zai iya inganta aminci da yawan layukan samar da semiconductor. Tare da ci gaba da ci gaba a fasaha, na'urori masu auna firikwensin laser za su taka muhimmiyar rawa a masana'antar semiconductor, suna ba da goyon baya mai ƙarfi ga ci gaban masana'antar mai dorewa.

Lokacin Saƙo: Maris-25-2025